Iron removing device and technology for fine powder of refractory material

A refractory material and fine powder technology, applied in the field of refractory materials, can solve the problems of difficult removal and utilization, high iron content, etc., and achieve the effect of safe and effective use, low investment cost, and reduced mining cost and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

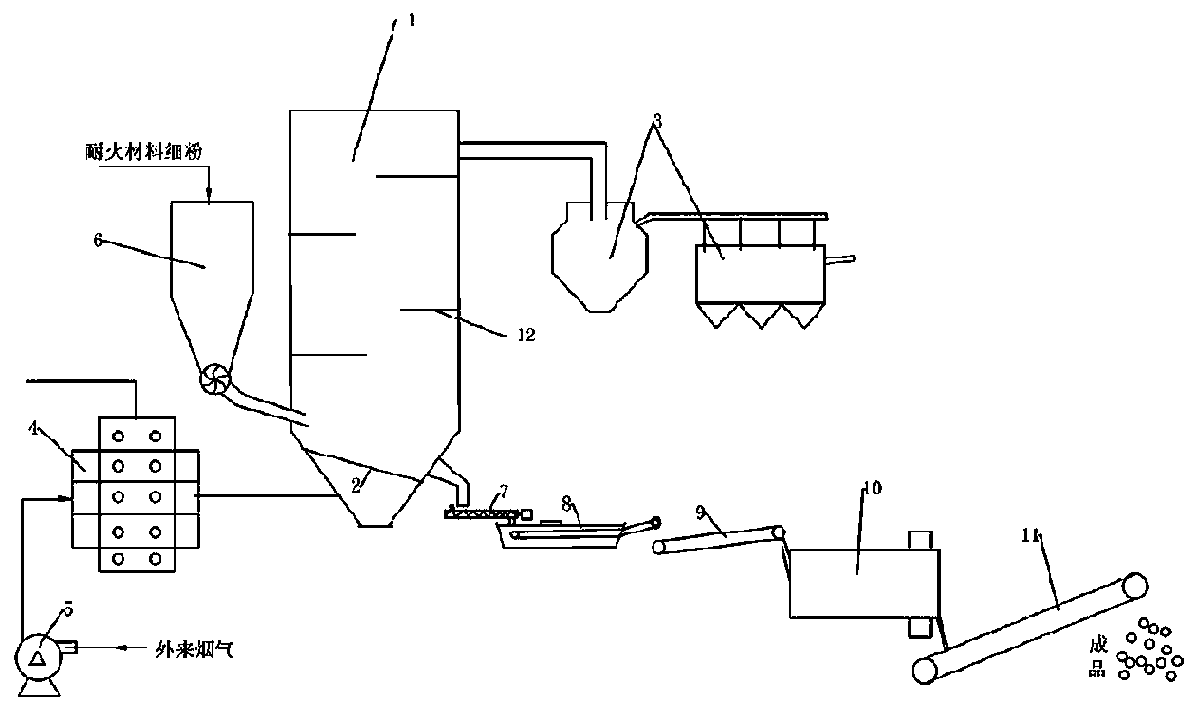

[0023] Such as figure 1 The shown iron removal device for refractory fine powder includes a fluidized fluidized furnace 1, which is provided with a smoke exhaust port for removing furnace gas from top to bottom, a feed port for receiving refractory fine powder, and a The outlet for removing the reduced refractory fine powder is provided with an air distribution plate 2 in the fluidized fluidized furnace 1, and the air distribution plate 2 is located below the outlet, and the air distribution plate 2 and the air distribution plate 2 The upper part of the fluidized furnace 1 encloses a boiling chamber, the air distribution plate 2 and the part of the fluidized furnace below the air distribution plate 2 enclose an air intake chamber, and the air intake chamber is provided with a pipe for conveying hot smoke into the boiling chamber. The flue gas inlet of the gas; the air distribution plate 2 is arranged obliquely, its highest point is located below the feed inlet, and the lowest ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com