A drainage gas production system and method for prolonging the life of gas wells in gas fields

A technology for drainage gas production and life cycle, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc. The effect of reducing fishing cost, improving extraction effect and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

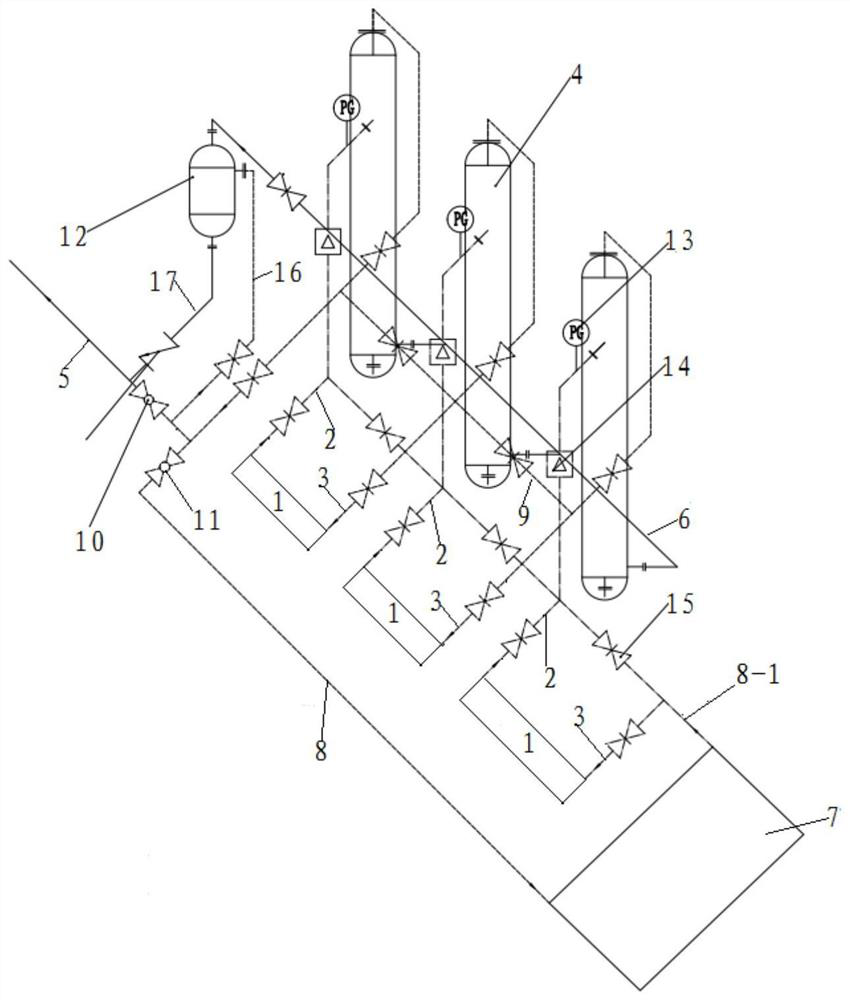

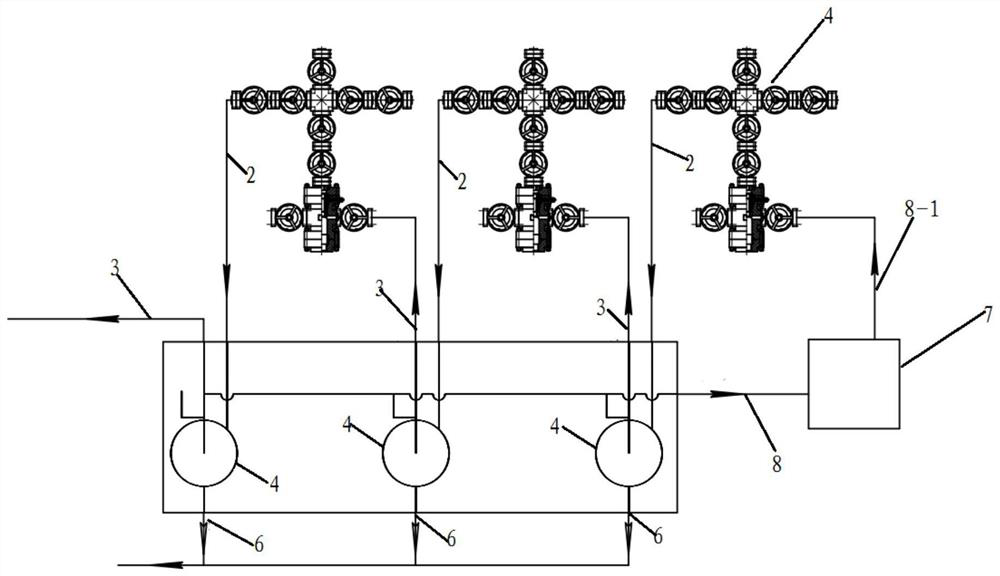

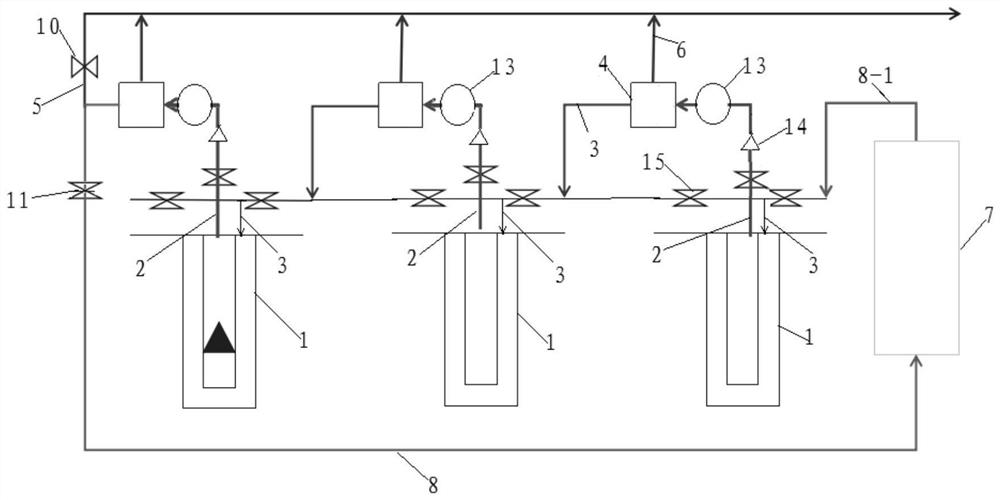

[0036] like Figure 1-3 As shown, an embodiment of the present invention provides a drainage gas production system for extending the life of a gas well in a gas field, comprising:

[0037] A plurality of gas-liquid separators 4 are in one-to-one correspondence with a plurality of gas wells 1 to be separated from gas and liquid;

[0038] A plurality of gas output pipes 2 are used to transport the gas in each gas well 1 to each gas-liquid separator 4 corresponding to it one-to-one, one end of each gas output pipe 2 is located in each gas well 1, and the other end is separated from each gas-liquid The air inlet of the device 4 is connected;

[0039] A plurality of gas input pipes 3 are used for injecting the gas separated by each gas-liquid separator 4 into the next gas well 1 adjacent to its corresponding gas well 1, and one end of each gas input pipe 3 is communicated with the gas outlet of each gas-liquid separator 4 , and the other end is located in the next gas well 1;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com