Oil displacement surfactant for high-temperature and high-salt oil reservoir as well as preparation method and application of oil displacement surfactant

A surfactant, high-temperature and high-salt technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem that alkylbenzene sulfonate cannot be compatible with formation fluid, the surfactant structure is easily destroyed, and cannot form Ultra-low interfacial tension and other issues, to improve the performance of salt resistance and resistance to divalent ions, wide application prospects and practical significance, and reduce the effect of oil-water interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

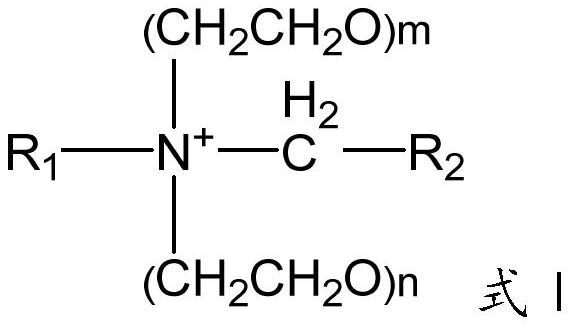

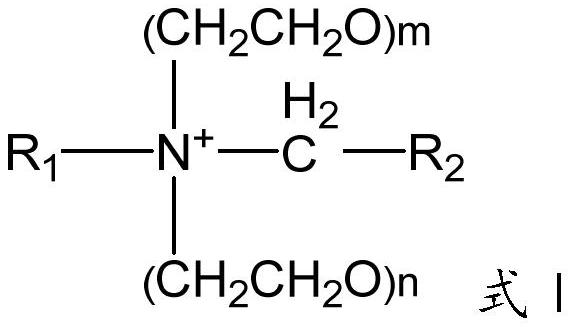

Method used

Image

Examples

Embodiment 1

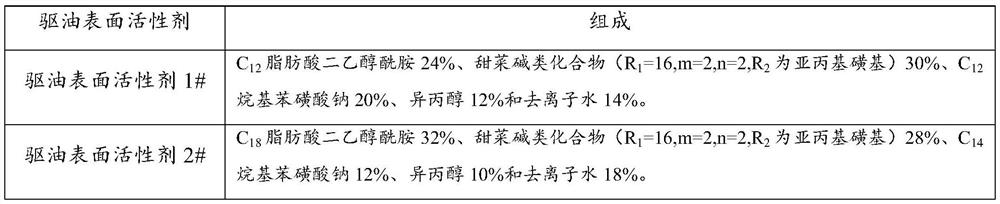

[0034] Embodiment 1 oil displacement surfactant 1#

[0035] Oil displacement surfactant 1# comprises the component of following percentage by weight: C 12 Fatty acid diethanolamide 24%, the betaine compound (R 1 =16, m=2, n=2, R 2 For propylene sulfo) 30%, C 12 Sodium alkylbenzene sulfonate 20%, isopropanol 12% and deionized water 14%.

[0036] The preparation method of oil displacement surfactant 1# may further comprise the steps:

[0037] Proportionally add isopropanol and water to the reaction vessel, and then add C 12 Fatty acid diethanolamide, betaine compound (R 1 =16, m=2, n=2, R 2 For propylene sulfo), C 12 Sodium alkylbenzene sulfonate was added in proportion, mixed and stirred for 30 minutes, then deionized water was slowly added in portions, and stirred evenly. The product is yellow homogeneous liquid with good water solubility, the solubility is not lower than 10g / 100g water, pH=8-10.

Embodiment 2

[0038] Embodiment 2 oil displacement surfactant 2#

[0039] Oil displacement surfactant 1# comprises the component of following percentage by weight: C 18 Fatty acid diethanolamide 32%, the betaine compound (R 1 =16, m=2, n=2, R 2 For propylene sulfo) 28%, C 14 Sodium Alkylbenzene Sulfonate 12%, Isopropanol 10%, and Deionized Water 18%.

[0040] The preparation method of oil displacement surfactant 1# may further comprise the steps:

[0041] Proportionally add isopropanol and water to the reaction vessel, and then add C 18 Fatty acid diethanolamide, betaine compounds (R 1 =16, m=2, n=2, R 2 For propylene sulfo), C 14 Sodium alkylbenzene sulfonate was added in proportion, mixed and stirred for 40 minutes, then deionized water was slowly added in portions, and stirred evenly. The product is yellow homogeneous liquid with good water solubility, the solubility is not lower than 10g / 100g water, pH=8-10.

Embodiment 3

[0042] Embodiment 3 oil displacement surfactant 3#

[0043] Oil displacement surfactant 3# comprises the composition of following percentage by weight: C 16Fatty acid diethanolamide 30%, the betaine compound (R 1 =14, m=5, n=6, R 2 is a sulfo group) 32%, C 16 Sodium alkylbenzene sulfonate 21%, isopropanol 10% and deionized water 7%.

[0044] The preparation method of above-mentioned oil displacement surfactant 3# comprises the steps:

[0045] Proportionally add isopropanol and water to the reaction vessel, and then add C 16 Fatty acid diethanolamide, betaine compounds (R 1 =14, m=5, n=6, R 2 is the sulfo group), C 16 Sodium alkylbenzene sulfonate was added in proportion, mixed and stirred for 60 minutes, then deionized water was slowly added in portions, and stirred evenly. The product is yellow homogeneous liquid with good water solubility, the solubility is not lower than 10g / 100g water, pH=8-10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com