Preparation process and special device for salt with green food label

A special equipment and preparation technology, applied in the direction of alkali metal chloride, etc., can solve the problems of edible salt turning green, affecting the quality of edible salt, and being volatile, so as to improve whiteness, stable and reliable iodine content, and prevent moisture attractive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

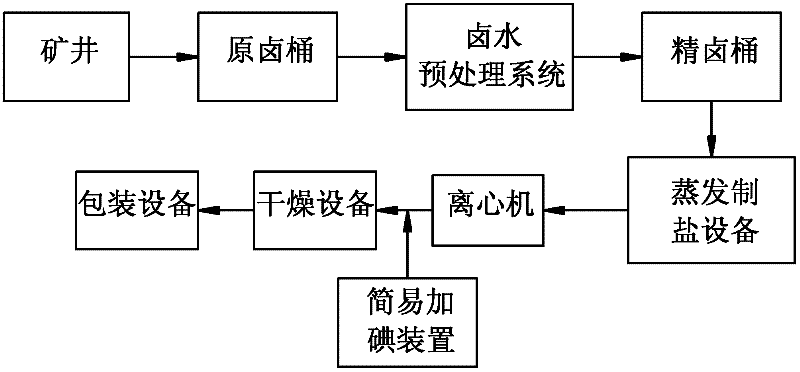

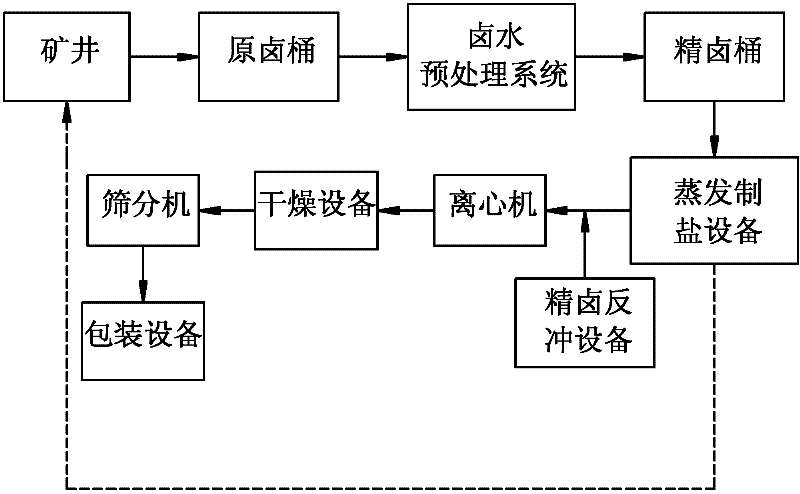

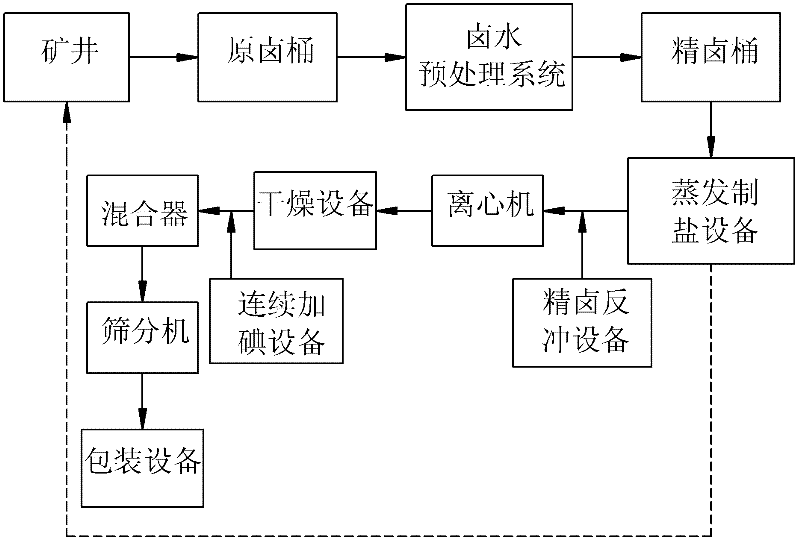

[0034] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0035] A green standard salt preparation process has the following steps:

[0036] One), carry out brine mining in the mine, and store in the original brine barrel;

[0037] 2), purify and pre-treat the original halogen in the original brine barrel, and store in the refined brine barrel after removing calcium and magnesium ions;

[0038] 3) Use evaporative salt-making equipment to evaporate and crystallize the purified brine in the brine barrel, extract the salt slurry, and use the condensed water produced by the evaporative salt-making equipment to mine brine;

[0039] 4) The salt slurry is discharged from the salt leg of the evaporative salt making equipme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com