Chlor alkali production waste acid recycling method

A technology of acid recovery and chlor-alkali, which is applied in the direction of neutralization water/sewage treatment, etc., can solve problems such as waste of resources, achieve the effects of reducing treatment costs, improving comprehensive utilization, and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

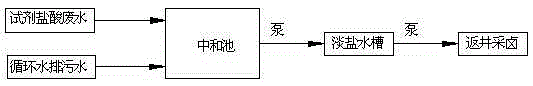

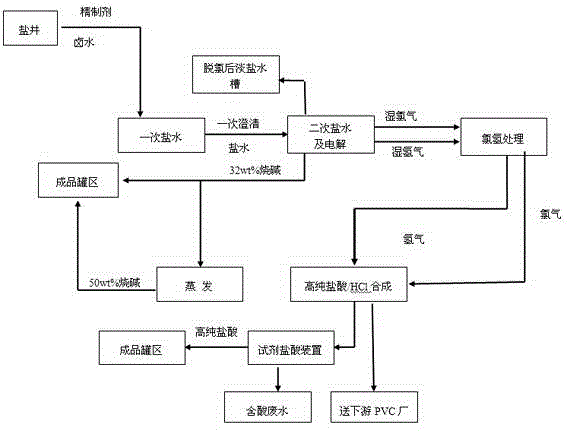

[0014] Chlor-alkali production waste acid recycling method provided by the invention, such as figure 2 As shown, the waste acid water produced by the chlor-alkali production reagent hydrochloric acid plant and the alkaline sewage of the circulating water system are jointly discharged into the waste water pool and mixed for neutralization. The pH of the waste acid water is 1-3, and the discharge volume is 2m 3 / h or so, the pH of the sewage from the circulating water system is 8.5-9.3, and the discharge volume is 20m 3 / h, the mixing mass ratio of the two is 1: (9-11), the pH after mixing and neutralization is 7-8, the content of mineral ions such as Ca, Mg and Na in the waste water after neutralization is high, and the content of impurities such as suspended solids is relatively high Therefore, it can replace the primary water and send it to the salt well for brine extraction, reducing the primary water consumption; further, the method of sending the neutralized wastewater i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com