Brine mining process

A process and brine technology, applied in the field of brine mining technology, can solve problems such as being not cheap and costing tens of millions of dollars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

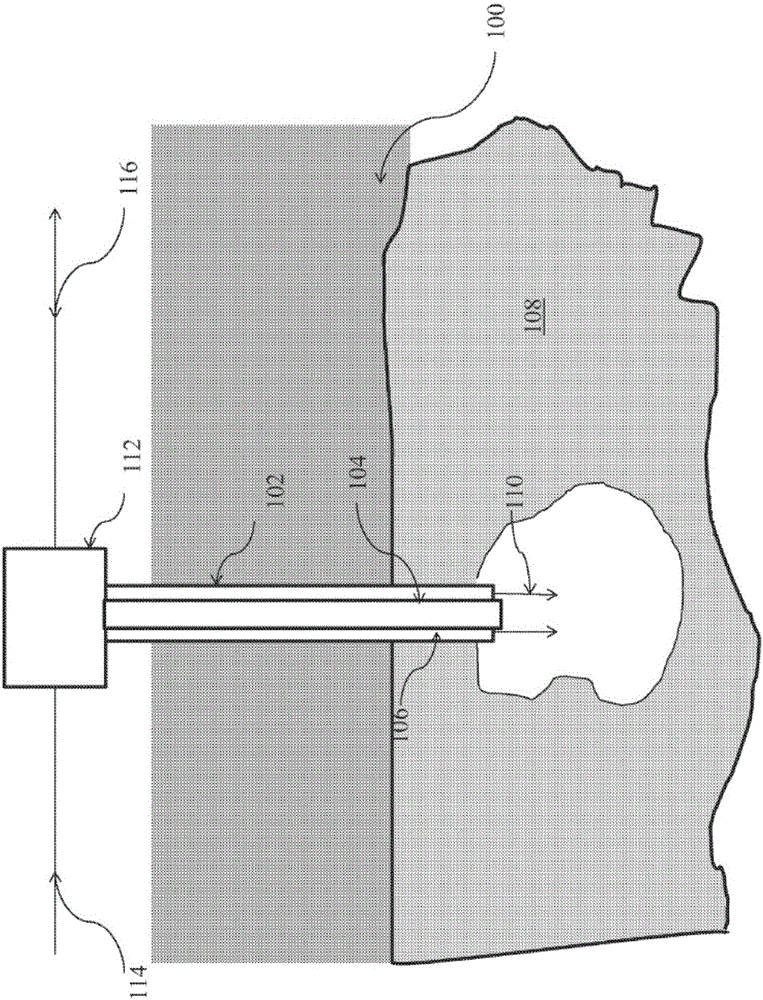

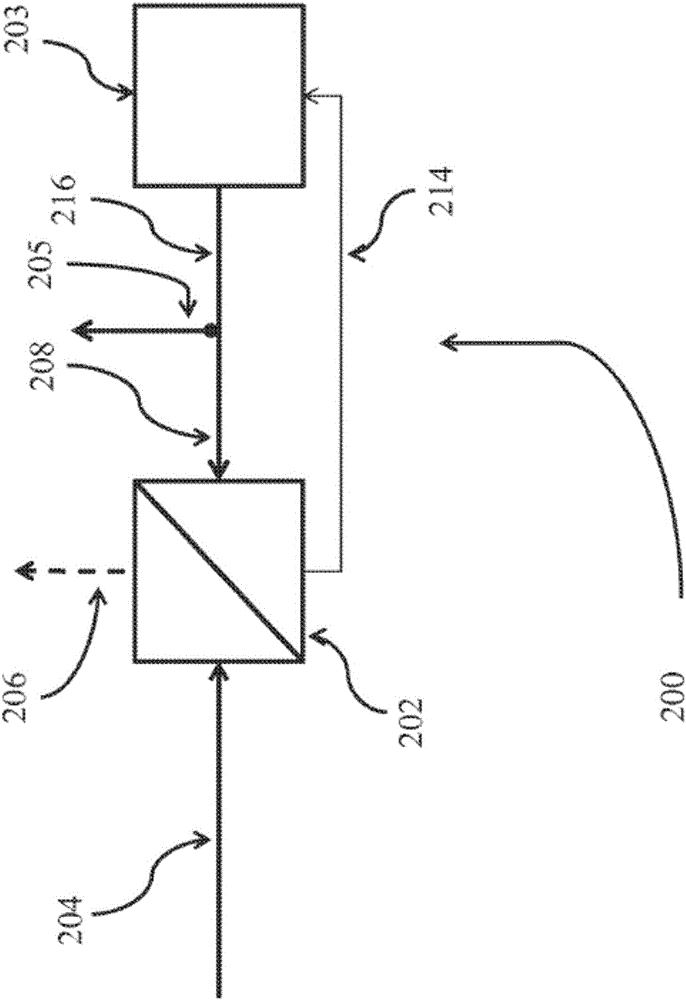

[0110] 351 t / h of feed stream comprising seawater with a salt concentration of 3.5% and 117 t / h of draw solution comprising 25% NaCl are supplied to 976 2 ) forward osmosis membrane (3.2m 2 Area, model FO_CTA, product 4040MS, purchased from HTI TM , AlbanyOR) single forward osmosis unit.

[0111] The outgoing feed stream 206 contains 4.1 NaCl with a flow rate of 301 t / h; while the outgoing draw stream 214 contains 17.5 NaCl with a flow rate of 167 t / h. This outgoing draw stream is then reintroduced into the brine mine for reconcentration to 25% NaCl, thus saving cost by not requiring purchased salt or evaporation to reconcentrate the draw stream.

[0112] Other streams that cannot be accommodated by the existing mine structure are stored, used in other processes or disposed of appropriately. Alternatively, an additional bore is provided to accommodate the flow. In this case, about 50t / h of fresh water was drawn from the forward osmosis unit to provide 67t / h of brine with 2...

Embodiment 2

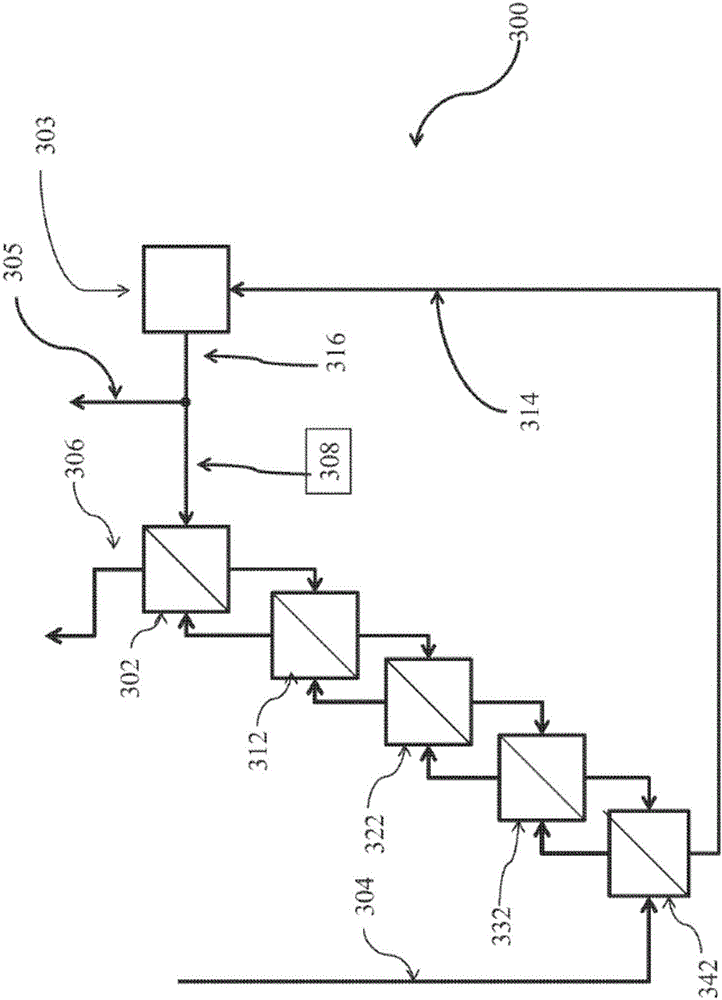

[0114] A feed stream containing 3.5% by weight NaCl and a draw stream containing 25% by weight NaCl were fed in series in counter-current fashion to a total of 1438 forward osmosis membranes (model FO_CTA; product 4040MS; HTI TM , Albany, Oregon) five forward osmosis units. The flow velocity and the salt concentration of the feed stream at each forward osmosis unit place and the draw stream and the number of used forward osmosis membranes in each forward osmosis unit are shown in Table 1 below, wherein reference image 3 Identify forward osmosis units. In this embodiment, the flow rate of the membrane is changed from 16 l / (h*m in unit 302 2 ) is reduced to 14l / (h*m in unit 312 2 ), to 12l / (h*m in unit 322 2 ), to 10l / (h*m in unit 332 2 ), to 8l / (h*m in unit 342 2 ), which is caused by the decrease of the salt concentration difference on both sides of the membrane. The outgoing draw stream is directed to the brine mine for reconcentration.

[0115] Table 1

[0116]

...

Embodiment 3

[0119] A feed stream containing 3.5% by weight NaCl was fed in parallel and a draw stream containing 25% by weight NaCl was fed in series to a total of 1415 forward osmosis membranes (model FO_CTA; product 4040MS; HTI TM , Albany, Oregon) five forward osmosis units. The flow rate and the salt concentration of the feed stream at each forward osmosis unit and the draw stream and the number of used forward osmosis membranes in each forward osmosis unit are shown in Table 2 below, where reference Figure 4 Identify forward osmosis units. In this embodiment, the flow rate of the membrane is changed from 17l / (h*m in unit 402 2 ) is reduced to 15 l / (h*m in unit 412 2 ), to 12l / (h*m in unit 422 2 ), to 10l / (h*m in unit 432 2 ), to 8l / (h*m in unit 442 2 ), which is caused by the decrease of the salt concentration difference on both sides of the membrane. The outgoing draw stream is directed to the brine mine for reconcentration.

[0120] Table 2

[0121]

[0122]

[0123]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com