A kind of brine mining well casing maintenance device and method

A well casing and casing technology is applied in the field of casing maintenance devices for brine mining wells, which can solve the problems of small production wellbore, high pump pressure, corrosion, etc. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

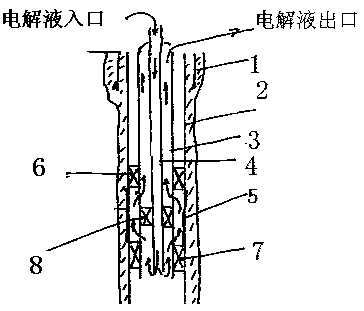

[0028] In order to overcome the serious corrosion of the existing downhole casing, which leads to smaller and smaller production boreholes, high pump pressure, low production, and impact on investment effects, the invention provides such as figure 1 Shown is a casing maintenance device and method for brine mining wells. The invention ensures the fixed size of the wellbore, keeps the circulation displacement unchanged after maintenance, reduces the casing corrosion rate, prolongs the service life of the casing and eliminates the problem of shrinking the size of the wellbore. Hidden dangers, to achieve the purpose of prolonging the production cycle of brine extraction wells under the condition of conventional circulation displacement.

[0029] A casing maintenance device for brine production wells, comprising a wellbore 1, a casing 2, an oil pipe 3 and a casing corrosion section 5, the casing 3 is fixed in the wellbore 1, and the casing on the casing 2 is corroded The upper and ...

Embodiment 2

[0037] Based on the above embodiments, in this embodiment, the upper packer 6 and the lower packer 7 have the same structure, and both are rubber barrel packers.

[0038] The inner packer 8 is a rubber barrel packer, and the inner packer 8 is smaller than the upper packer 6 .

[0039] Thirty through holes are opened on the oil pipe 3 at the corrosion section 5 of the casing.

[0040] The through hole is a φ12-16mm through hole. The diameter of these through holes is φ14 in this embodiment. Such holes can be evenly distributed on the oil pipe 3 or randomly distributed, and the purpose is to connect the oil pipe 3 and the casing 2 so that the electrolyte can circulate smoothly.

Embodiment 3

[0042] On the basis of the above-mentioned embodiments, a casing maintenance method for brine production wells is provided in this embodiment, which is characterized in that: the specific steps are:

[0043] Step 1 Determine the casing corrosion section 5 to be maintained, and scrape the casing 2 of the casing corrosion section 5 to expose the original metal surface;

[0044] Step 2: Lower the tubing 3 with the upper packer 6 and the lower packer 7 into the well, and make the casing corrosion section 5 located between the upper packer 6 and the lower packer 7;

[0045] Step 3 Pressurize the wellhead. When the wellhead pressure is 3MPa, the upper packer 6 and the lower packer 7 are set to isolate the casing 2 in the casing corrosion section 5;

[0046] Step 4 Lower the hollow sucker rod 4 with the inner packer 8 into the well, and the inner packer 8 is located on the corrosion section 5 of the casing;

[0047] Step 5 Pressurize the wellhead. When the wellhead pressure is 5MPa,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com