Air cushion type brine mining method for salt rock stratum containing high-impurity salt rock and mudstone interlayer

An air-cushion, salt rock technology, applied in the field of brine mining, can solve the problems of high impurity salt rock formation cavity shape control and other problems, and achieve the effect of reducing side dissolution, regular shape and good sales price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

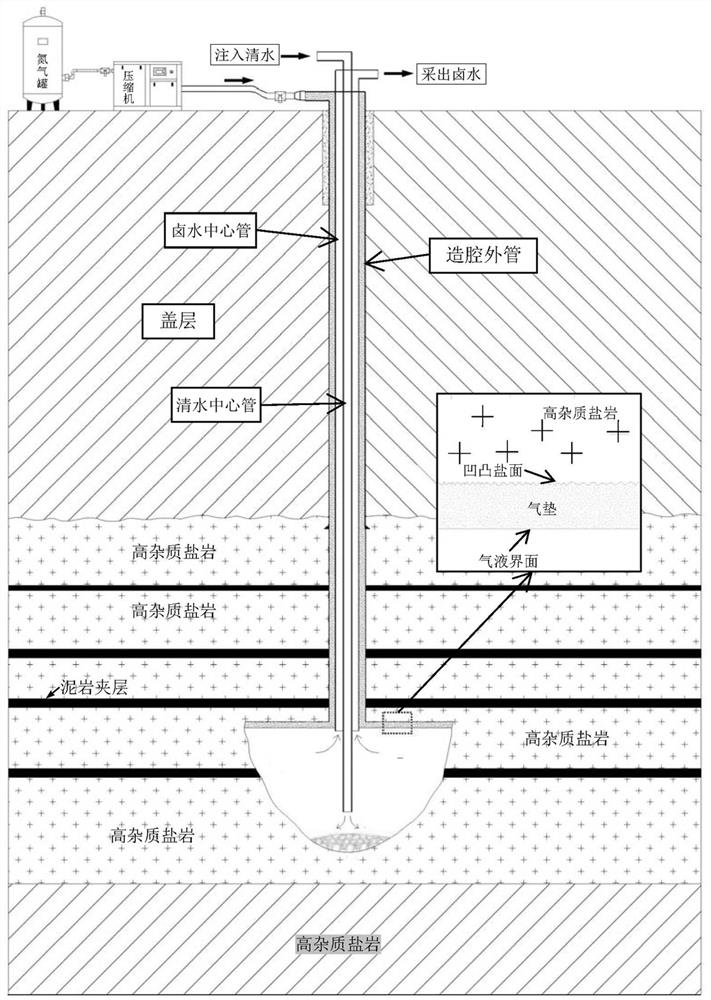

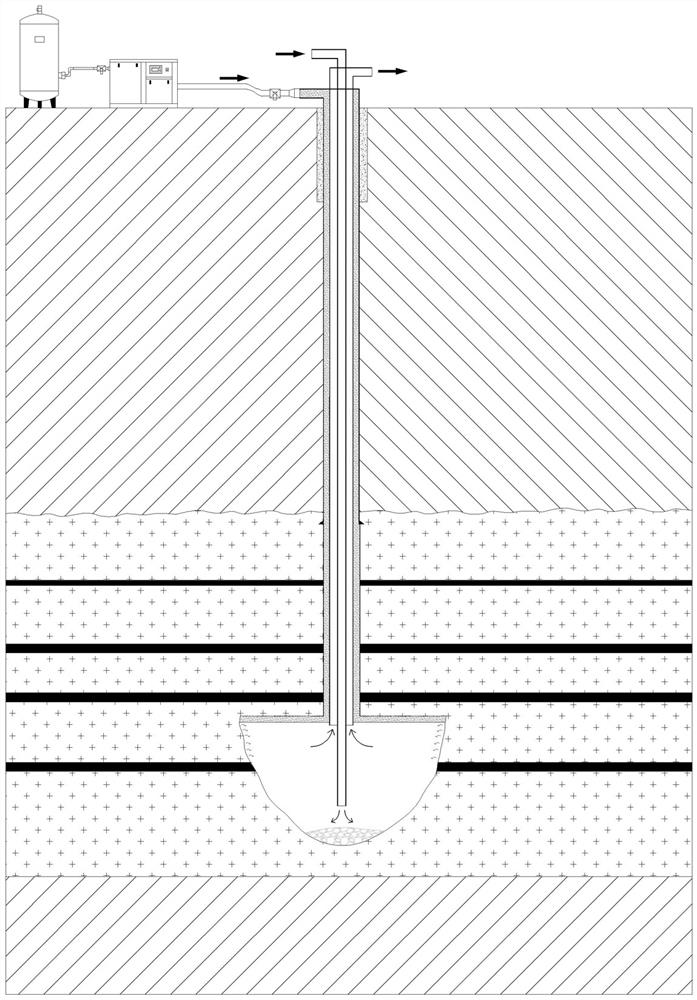

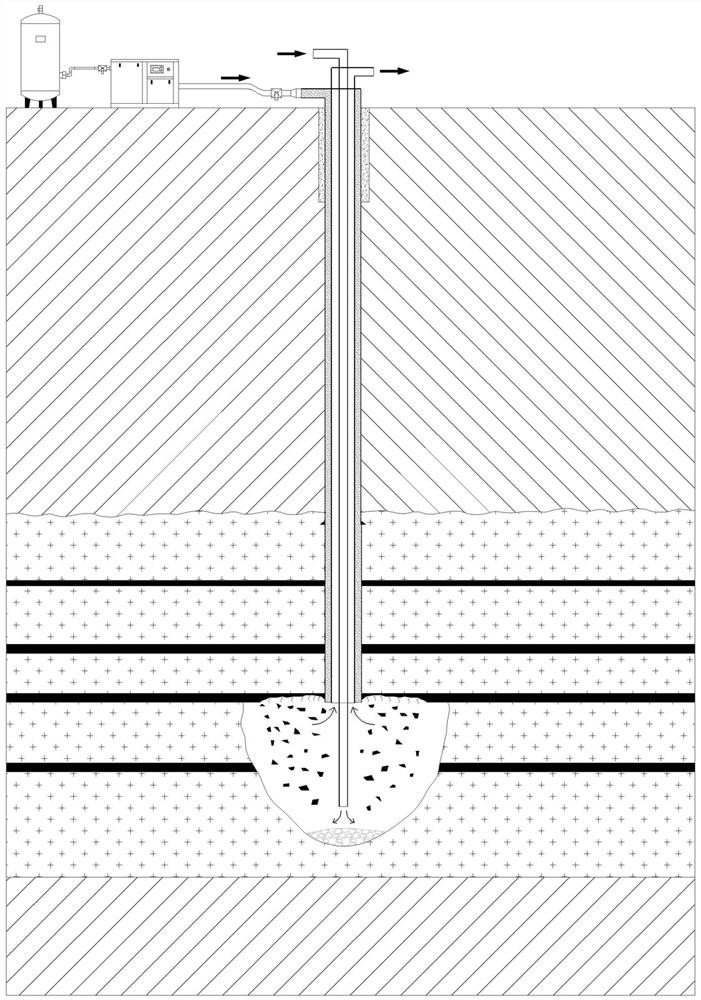

[0023] An air cushion brine mining method for salt rock formations containing high-impurity salt rock and mudstone interlayers, using such as figure 1 The air-cushion type brine collection device shown, the air-cushion type brine collection device includes a three-layer casing, and the three-layer casing is respectively a clear water central tube, a brine central tube, and a cavity-making outer tube that are sequentially set from the inside to the outside , the clear water central pipe is used to inject clear water into the dissolution chamber in the past, the brine central pipe is used to collect brine from the dissolution chamber, the outer pipe of the cavity is used to inject gas into the dissolution chamber in the past, the brine central pipe and the clear water central pipe A brine collection channel is formed, and a gas injection channel is formed between the cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com