Method for increasing brine output from brine mining well in salt lake mining area

A technology for extracting brine and mining areas, which is applied in the field of extracting brine in salt lake mining areas. It can solve the problems of low brine output in a single well, high production cost, and small permeability coefficient, and achieve the effect of expanding the area of brine output, making full use of it, and increasing the amount of brine extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

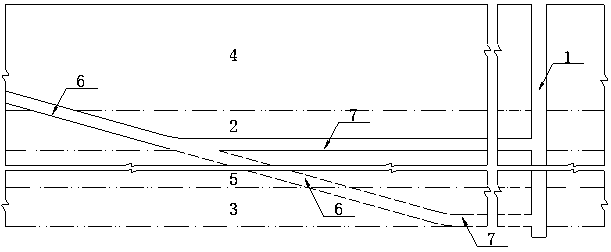

[0020] See figure 1 , This embodiment includes the following steps:

[0021] (1) Build vertical deep well

[0022] Determine the design depth of the vertical deep well 1 according to the occurrence conditions of the halogen-bearing ore layer. The bottom of the well is located 5m below the bottom plate of the lowermost planned mining layer—the confined brine layer II3, and the diameter of the well is 1000mm. Because the formation is relatively stable, in this example The casing is not installed in the middle to protect the wall; the lower part of the vertical well is equipped with a deep well pump to pump brine;

[0023] (2) Construction of directional horizontal wells

[0024] The mining area contains two mineable confined brine layers. The upper confined brine layer I2 is first extracted during mining; therefore, after the directional well passes through the overlying rock layer 4, horizontal section 7 is constructed along the bottom plate of the confined brine layer I2. The hole d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com