Repeated pressure boosting internal combustion engine

A technology of internal combustion engines and turbochargers, applied in the field of power machinery, can solve the problems of reduced fuel utilization, low conversion rate of mechanical energy, increase of ineffective energy, etc., and achieve the effect of increasing conversion rate, good air tightness and overall performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

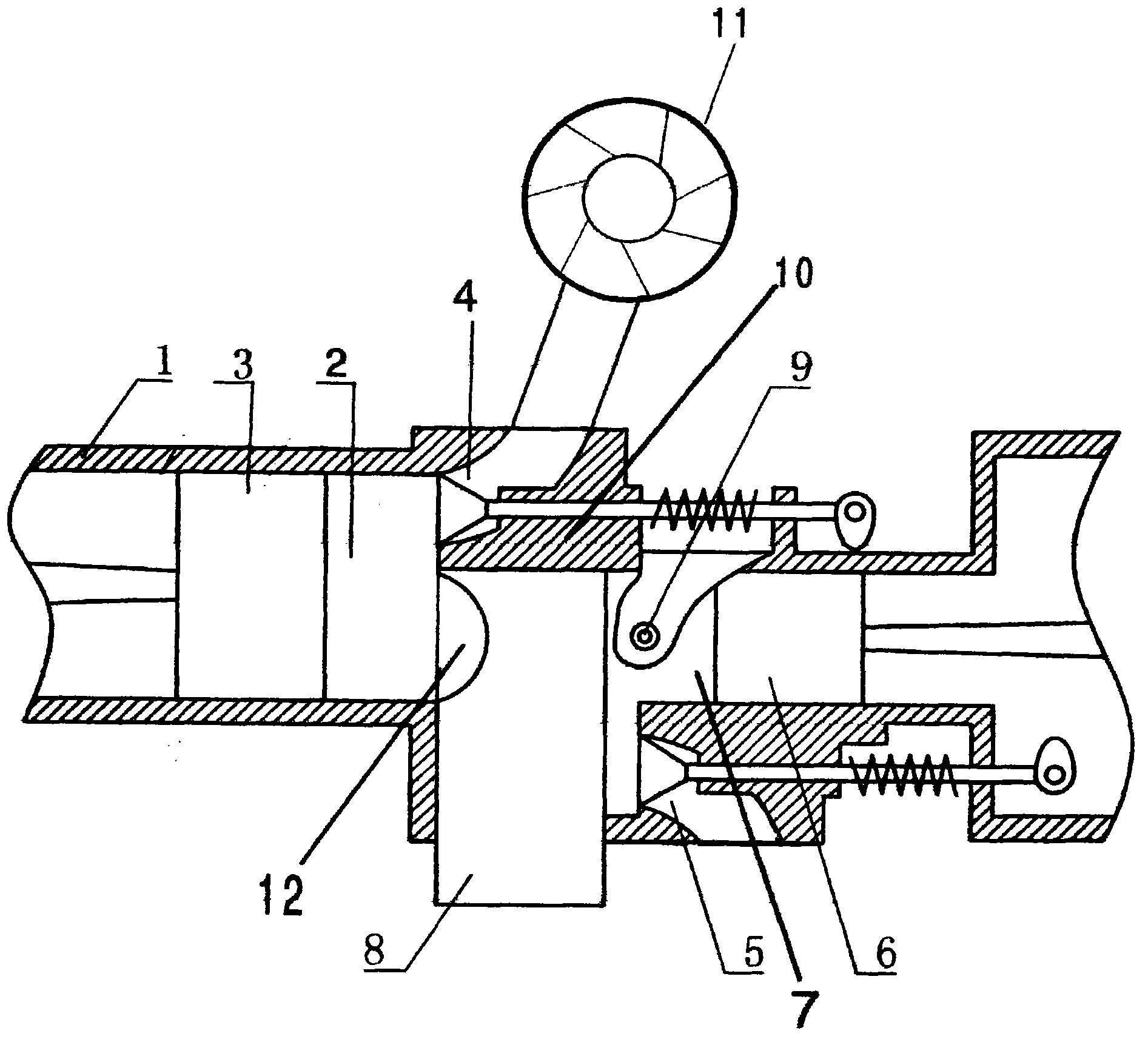

[0010] The multiple supercharging internal combustion engine of the present invention comprises a cylinder block 1, a compression cylinder 2 and a power cylinder 7 opposite to each other in the cylinder body 1, and the tops of the two cylinders are connected with a cylinder head 10, and a rotary gas distribution valve 8 is embedded in the cylinder head 10, and the compression cylinder 2. A compression piston 3 matched with it is provided inside, and an intake valve 4 is provided at the top, and the turbocharger 11 is connected and sealed with the intake valve 4 by an intake duct; Piston 6 is provided with exhaust valve 5 on one side, and is provided with fuel injector or sparking plug 9 on one side of the working cylinder on its cylinder head 10 . In actual work, the compression piston 3 and the power piston 6 move towards each other. When the compression piston 3 moves toward the cylinder head 10, the intake valve 4 is closed, and the compressed gas in the cylinder 2 is compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com