Patents

Literature

33results about How to "Small working volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

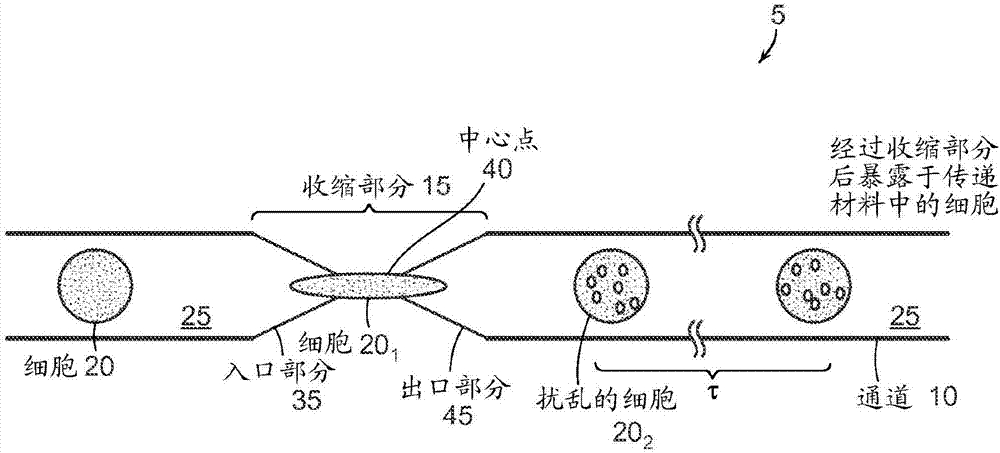

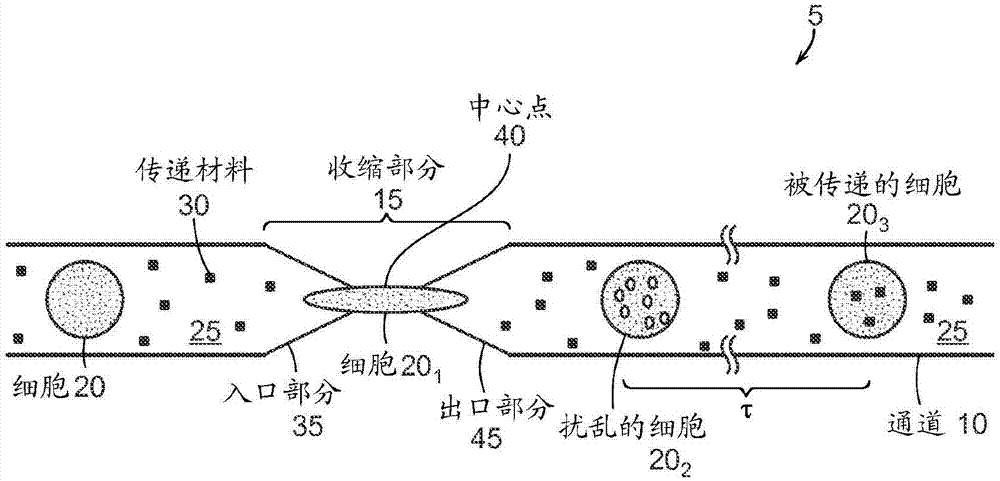

Intracellular delivery

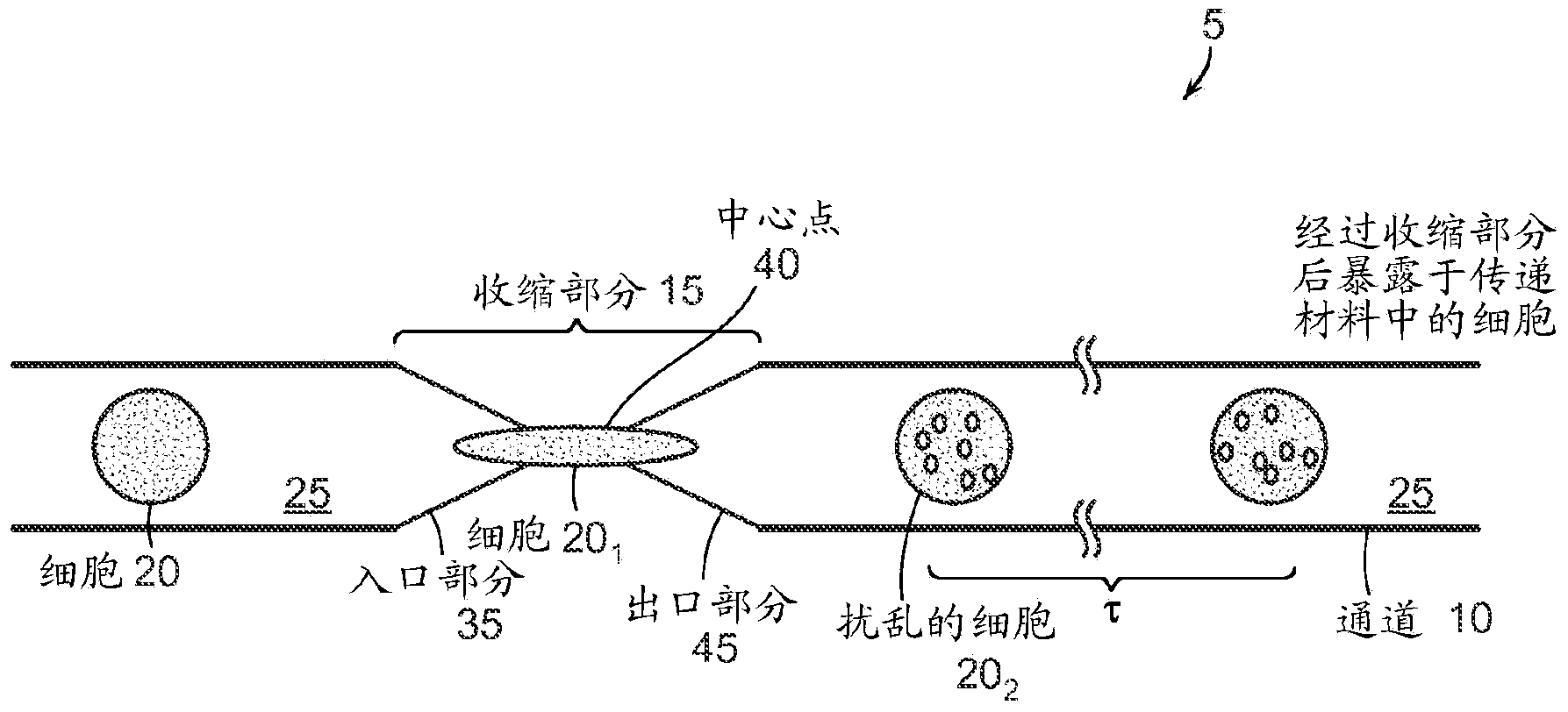

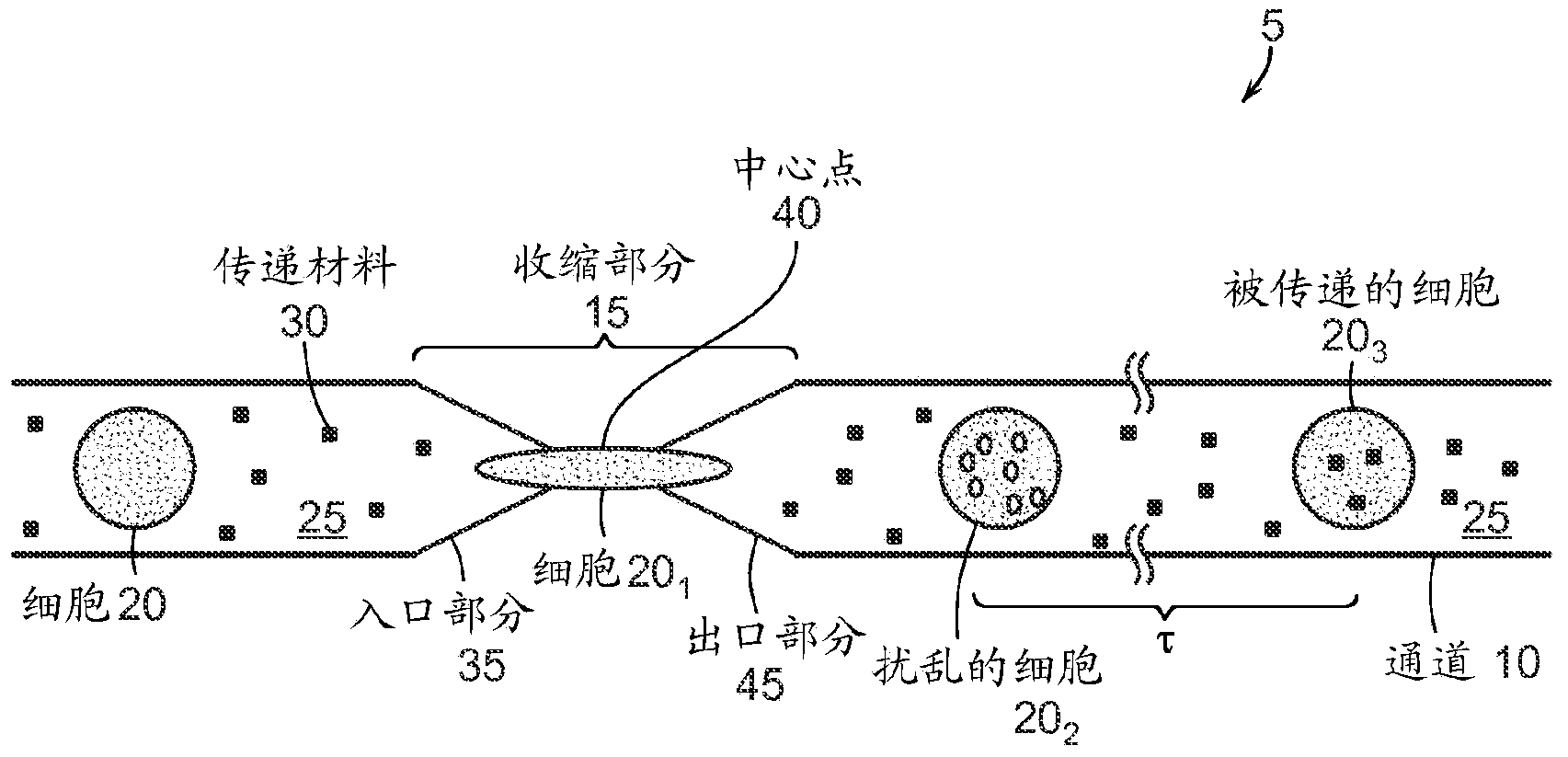

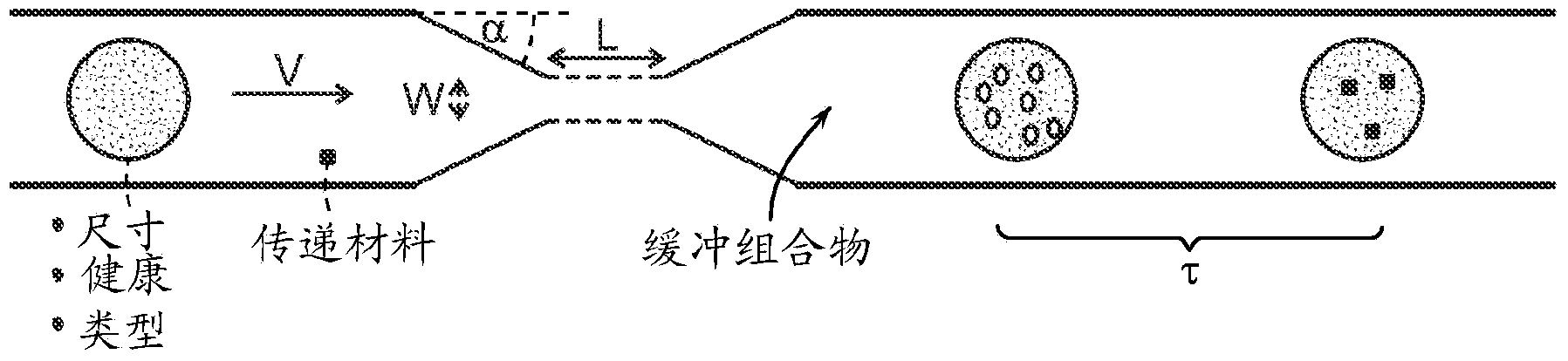

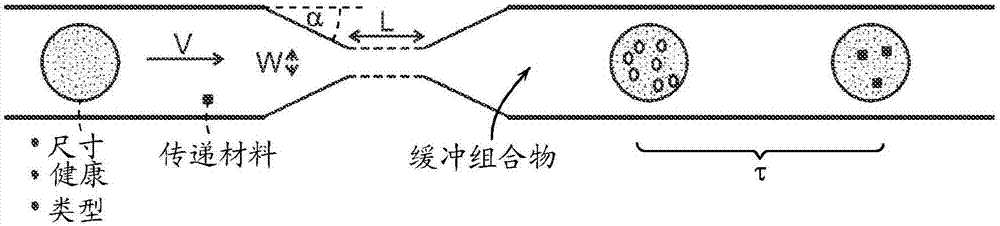

ActiveCN103987836ARestrict/Eliminate FunctionShorten the timeMicroinjection basedNanomedicineCell membraneMicrofluidic channel

A microfluidic system for causing perturbations in a cell membrane, the system including a microfluidic channel defining a lumen and being configured such that a cell suspended in a buffer can pass therethrough, wherein the microfluidic channel includes a cell-deforming constriction, wherein a diameter of the constriction is a function of the diameter of the cell.

Owner:MASSACHUSETTS INST OF TECH

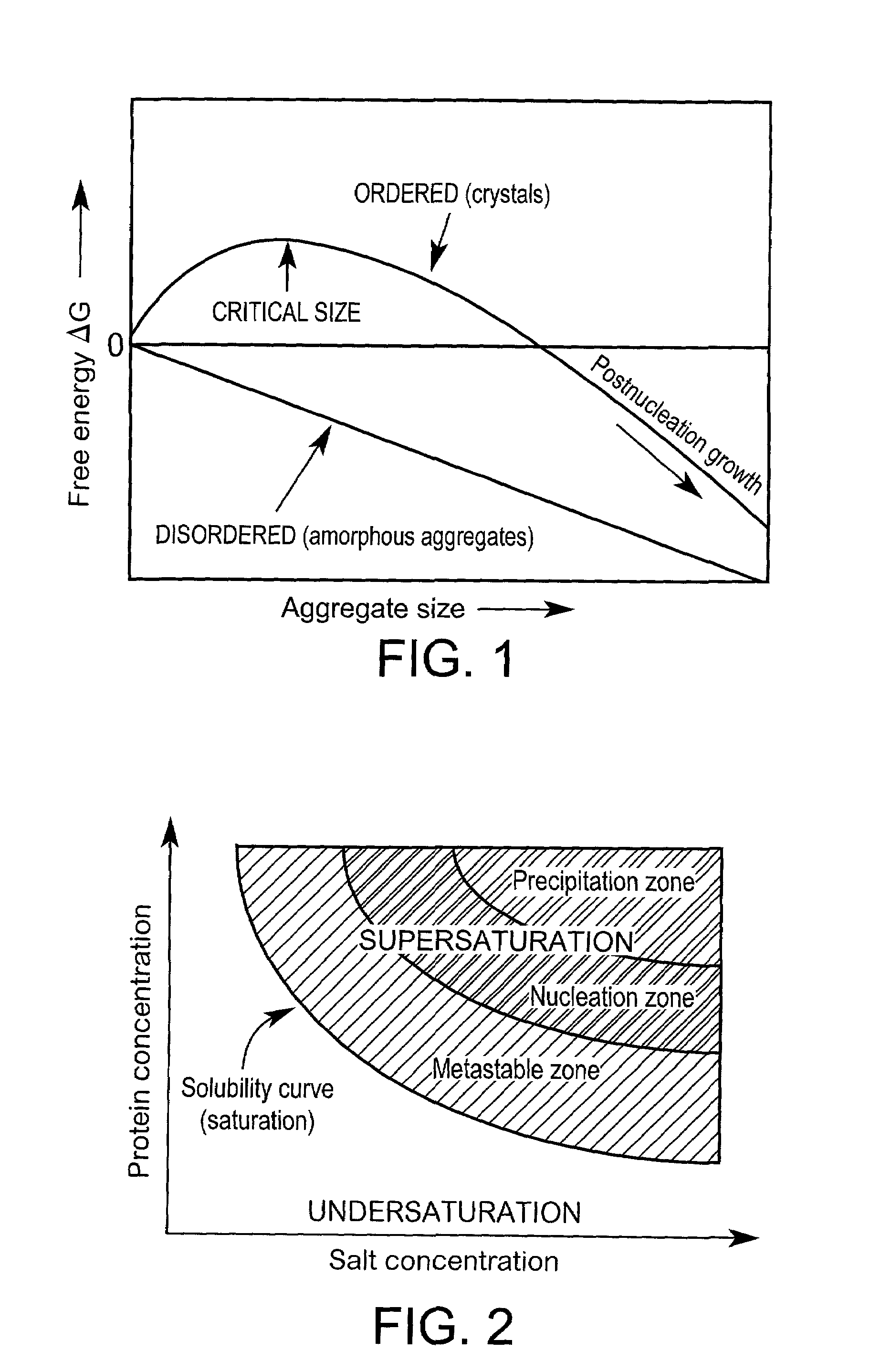

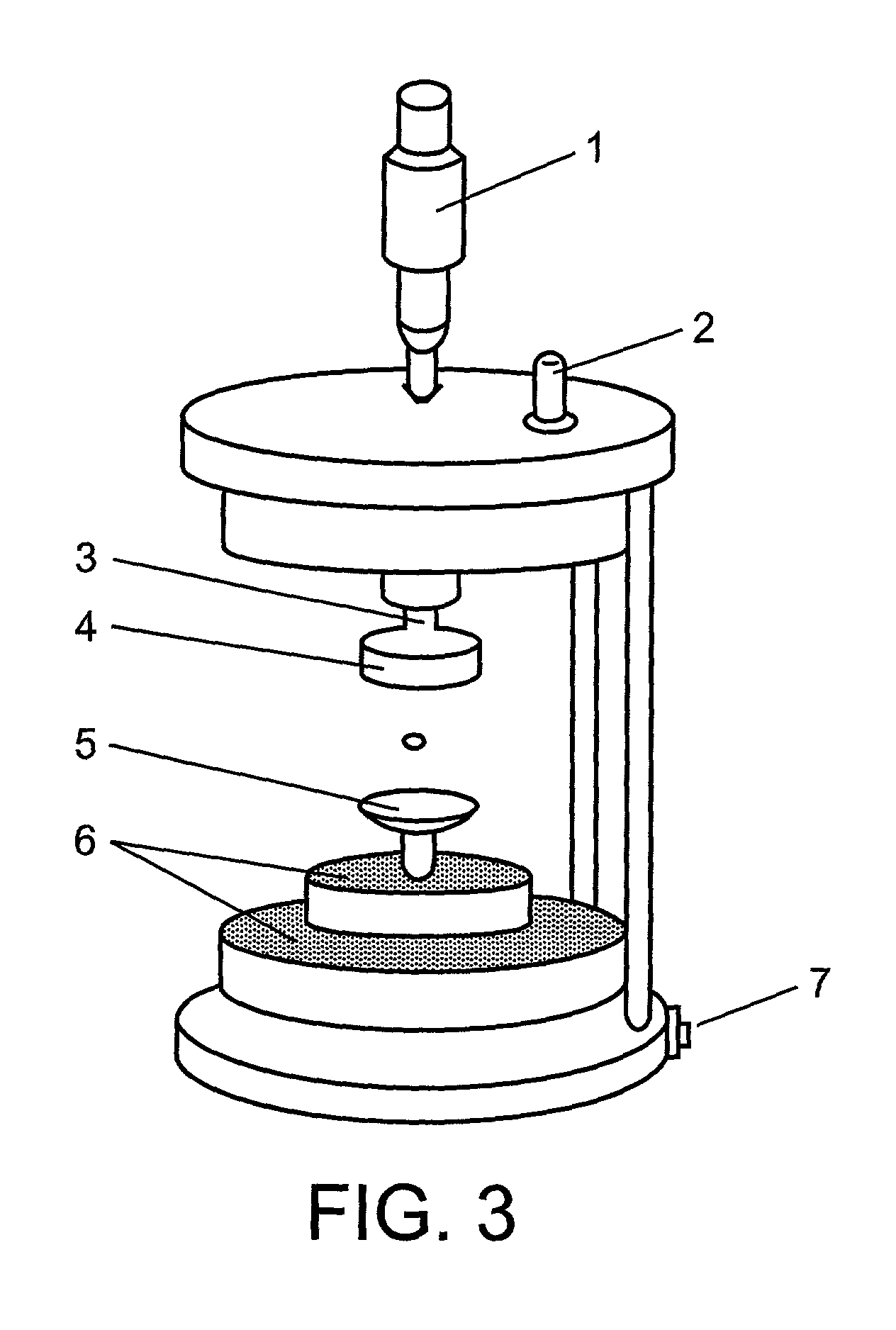

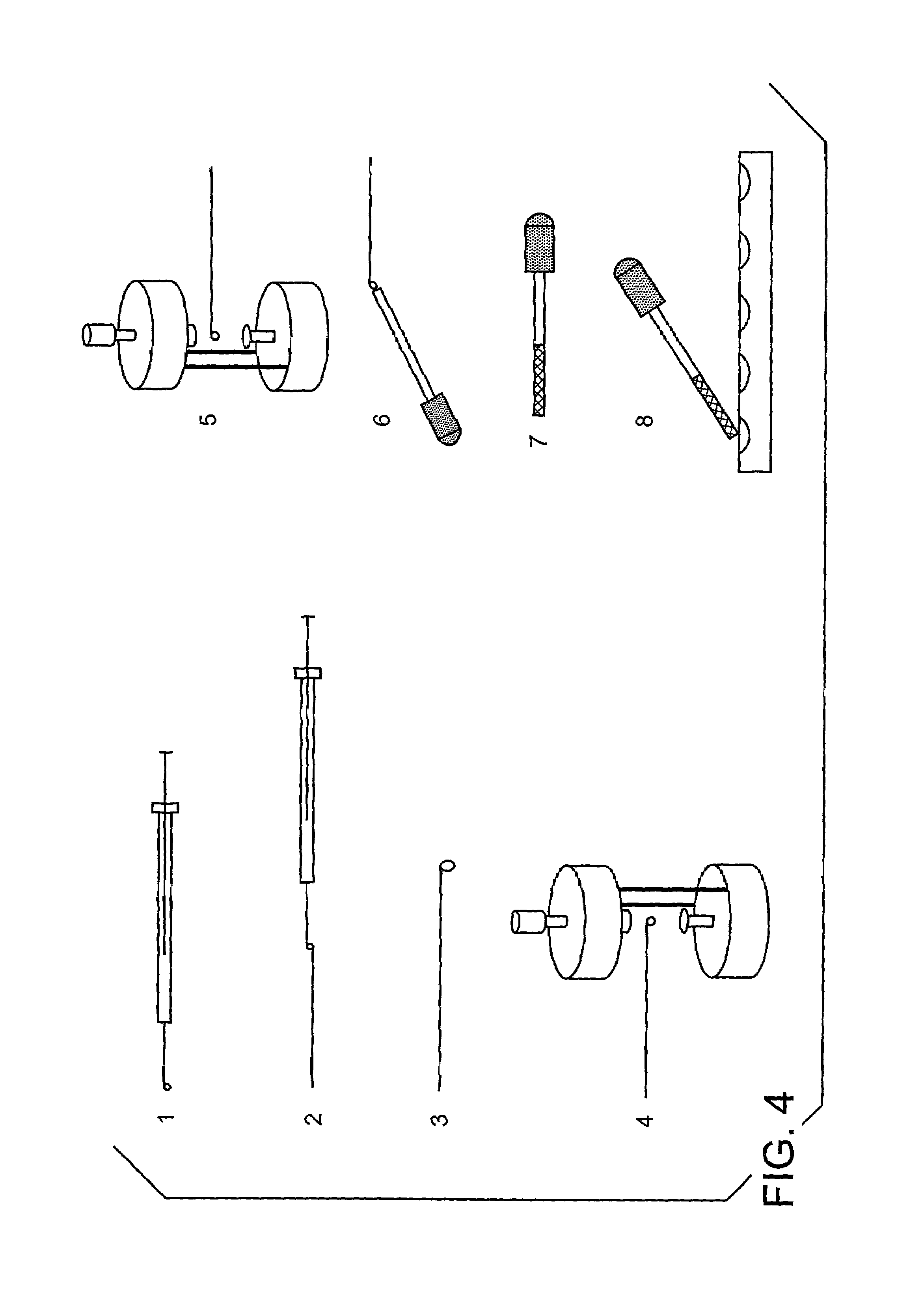

Method for screening crystallization or amorphous stage conditions for molecules

InactiveUS7200493B2Reduce usageSimple processFrom normal temperature solutionsFlow propertiesNucleationSupersaturation

A system and a method for screening of nucleation tendency of a molecule, such as a macromolecule, based on acoustic, electrostatic or hybrid acoustic / electrostatic levitation of a droplet for optimizing crystallization conditions for said molecule. This allows for a controlled approach to determination of supersaturation and allows for screening of crystal nucleation conditions within minutes and hours instead of months and years with a minute amount of starting material compared to conventional crystallization methods.

Owner:CHEM HOLOVOICE

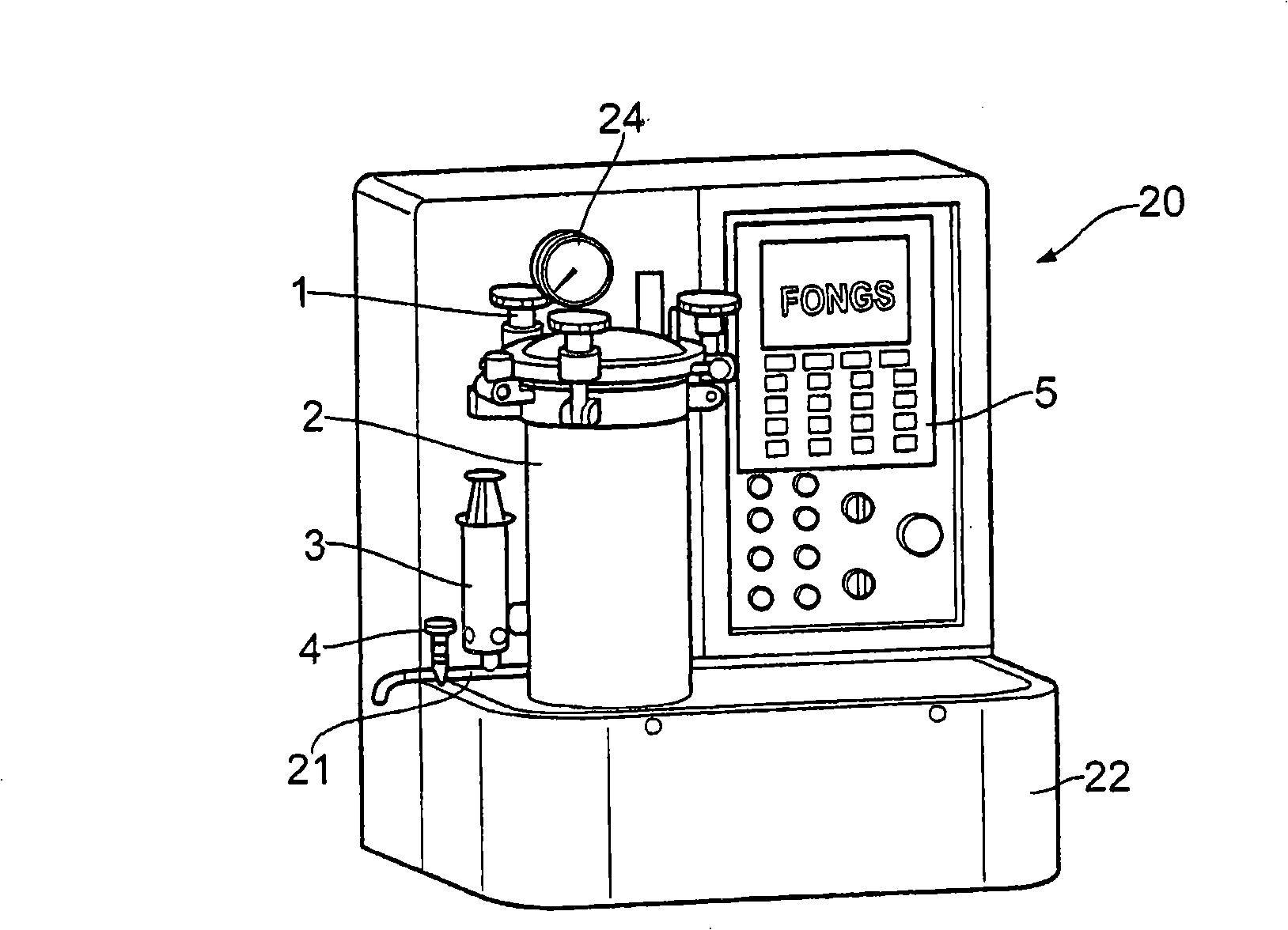

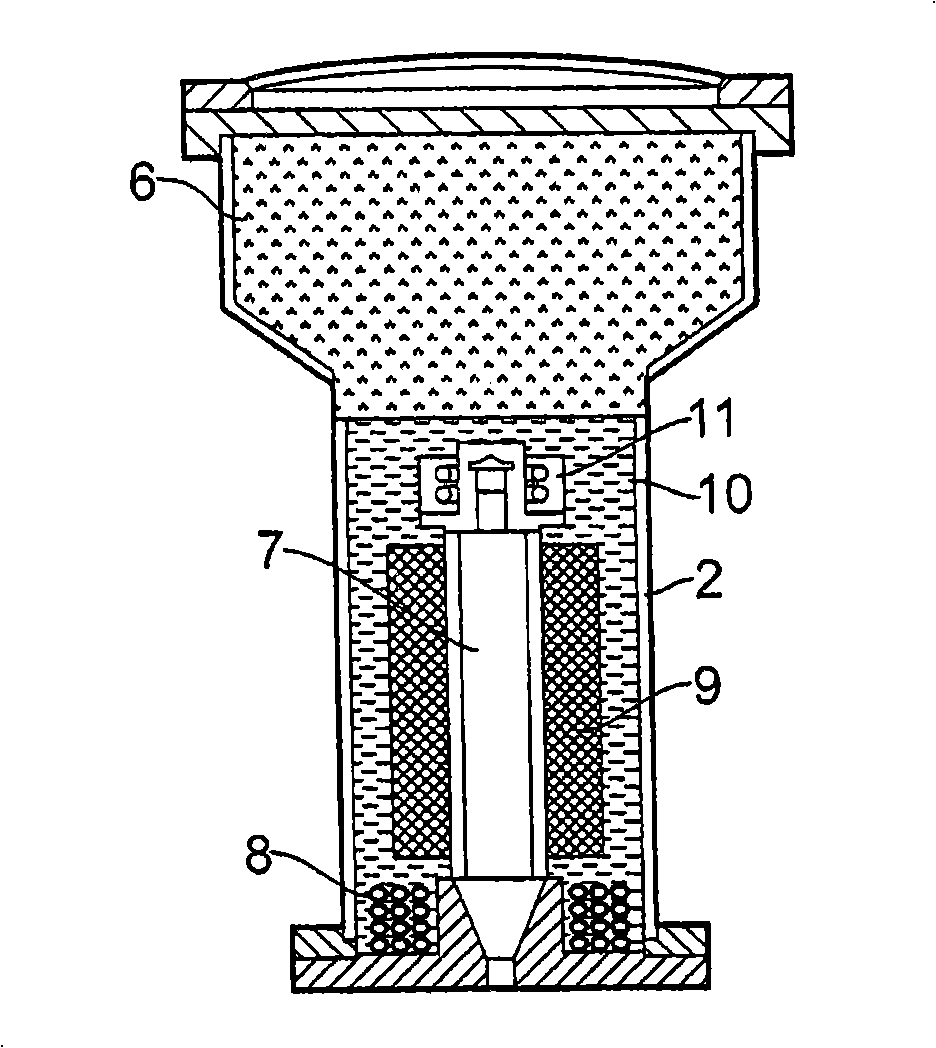

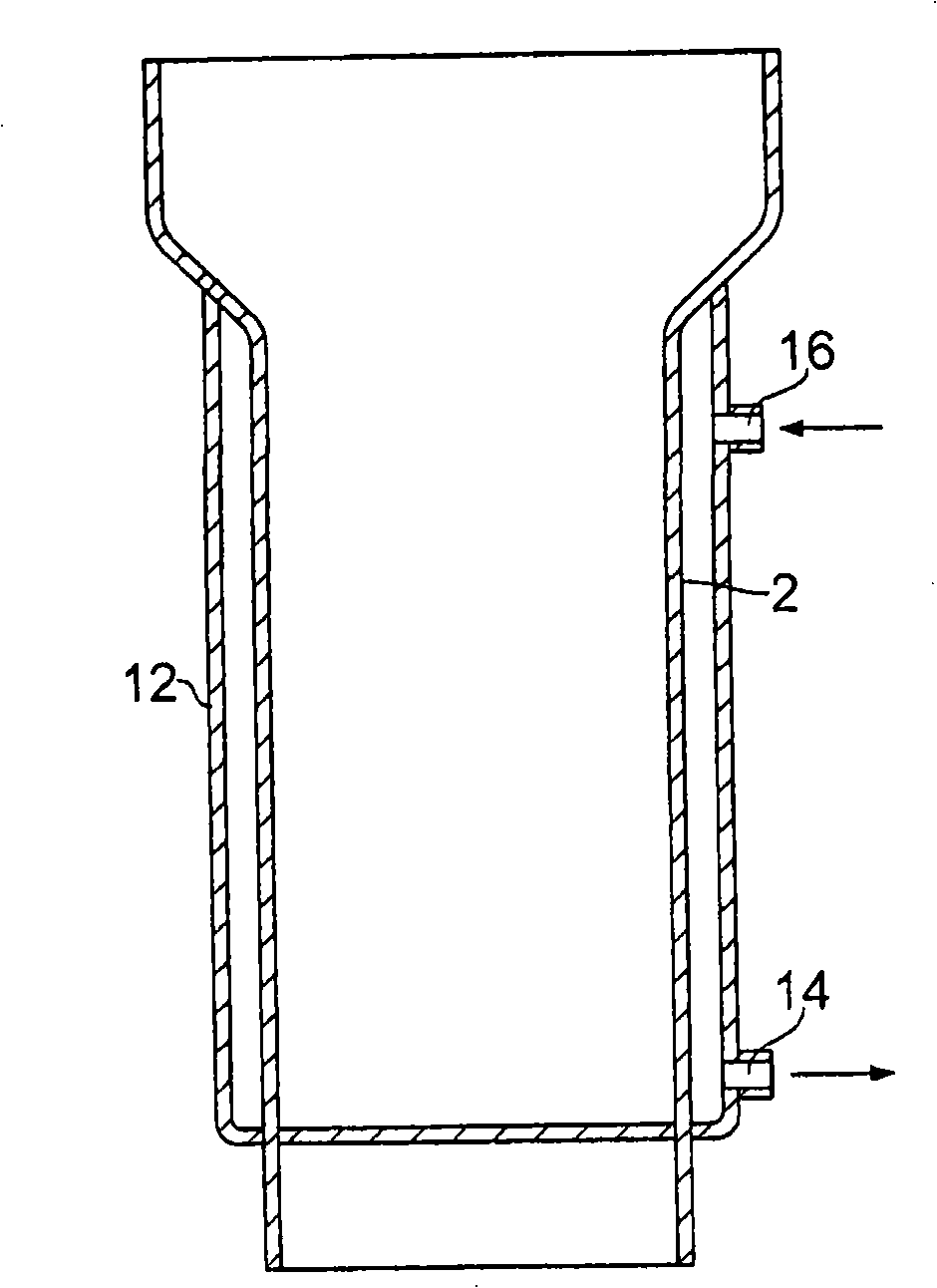

Sample package dyeing machine

InactiveCN101302690ASave spaceSave energyTextile treatment containersTextile treatment dyeing devicesSingle sampleYarn

A dyeing machine (2) for dyeing a sample yarn package (9) comprises a kier (2), a spindle (7) mounted in the kier for supporting a sample yarn package, and a dye liquor circulation system (25) operable to circulate dye liquor through the sample yarn package with inside-to-out and outside-to-in flow directions, the kier and the spindle configured to accommodate a single sample yarn package with a weight less than 1.2 kg, and the machine having an operating volume such that a single sample yarn package weighing less than 1.2 kg can be dyed using a liquor ratio of substantially 1:6.

Owner:FALMER INVESTMENTS LTD

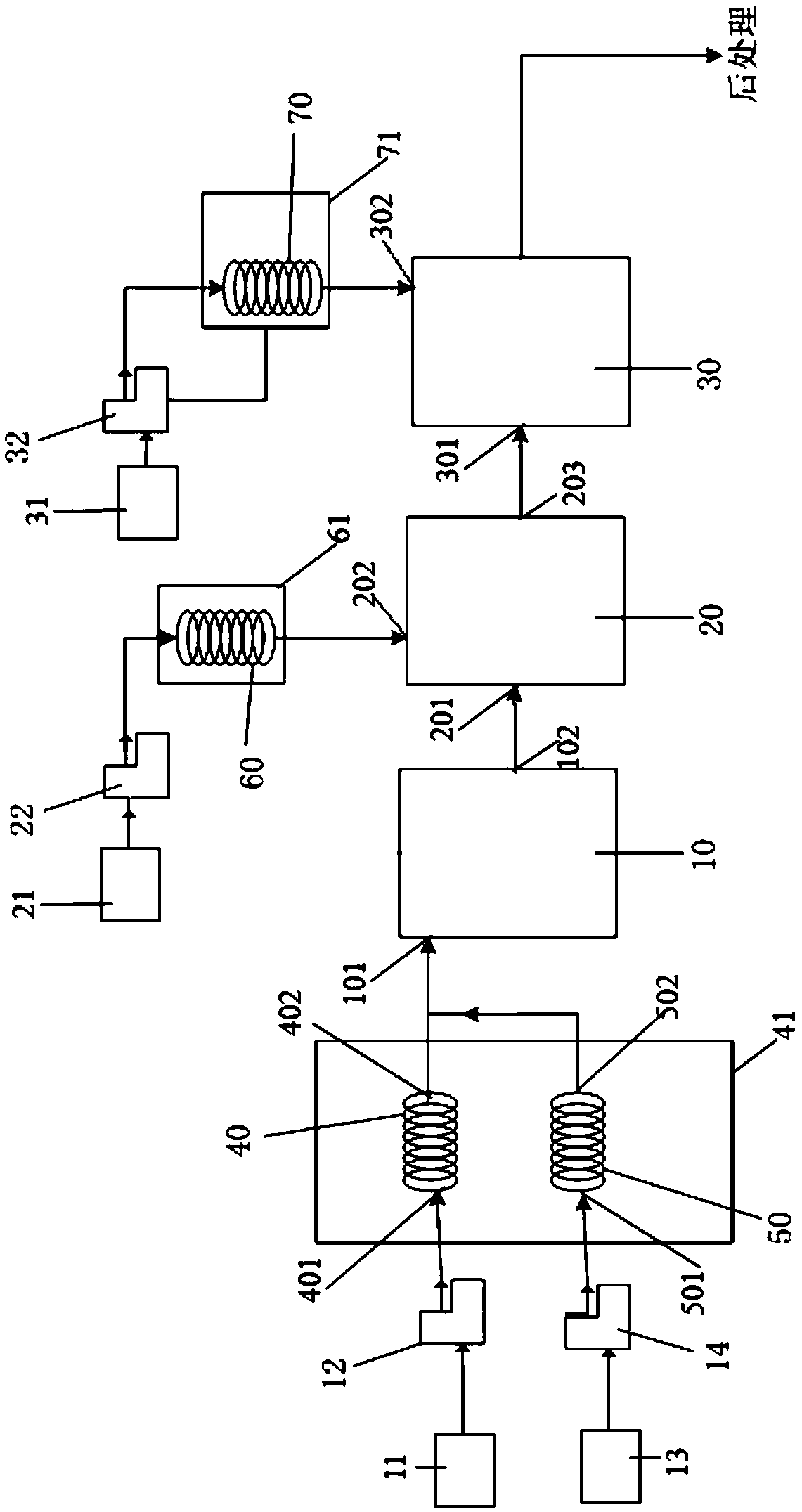

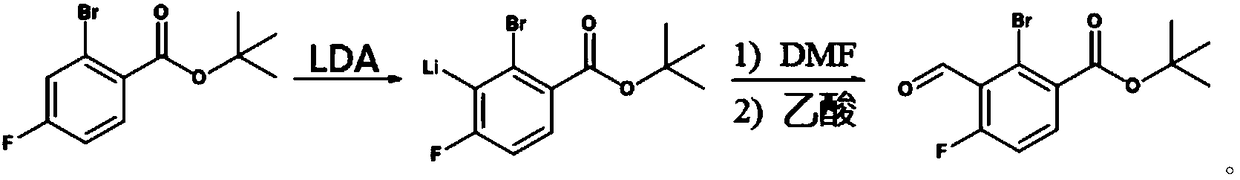

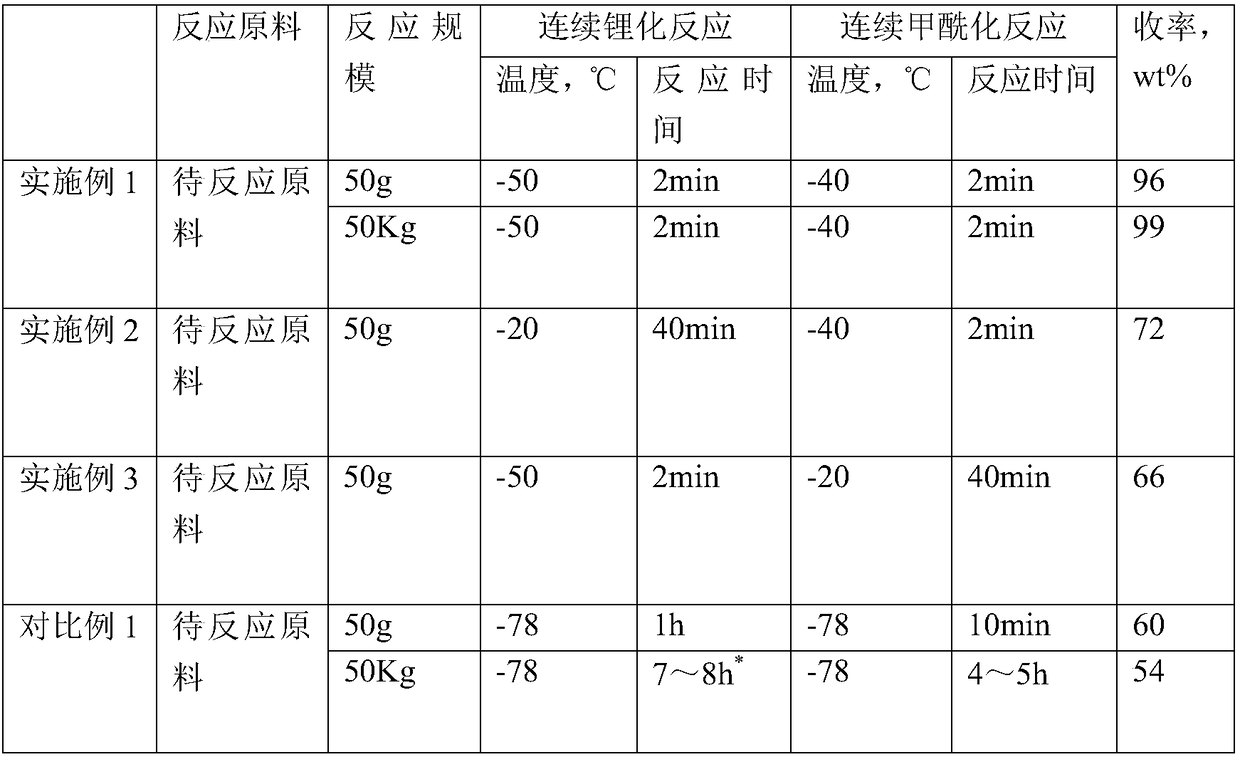

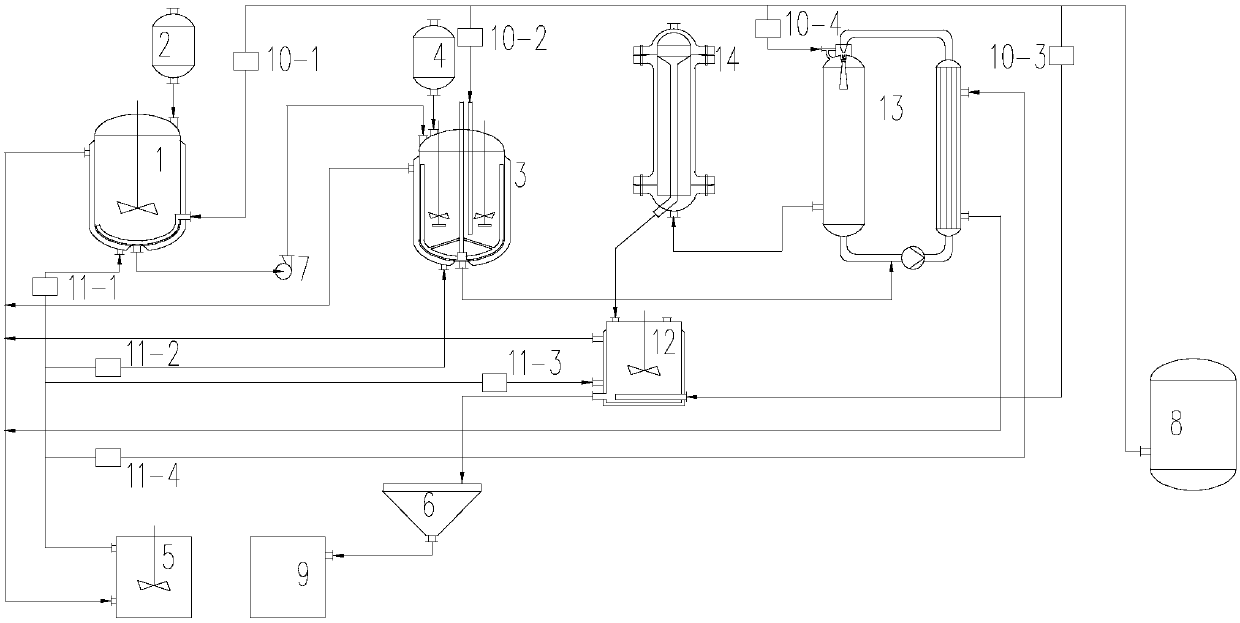

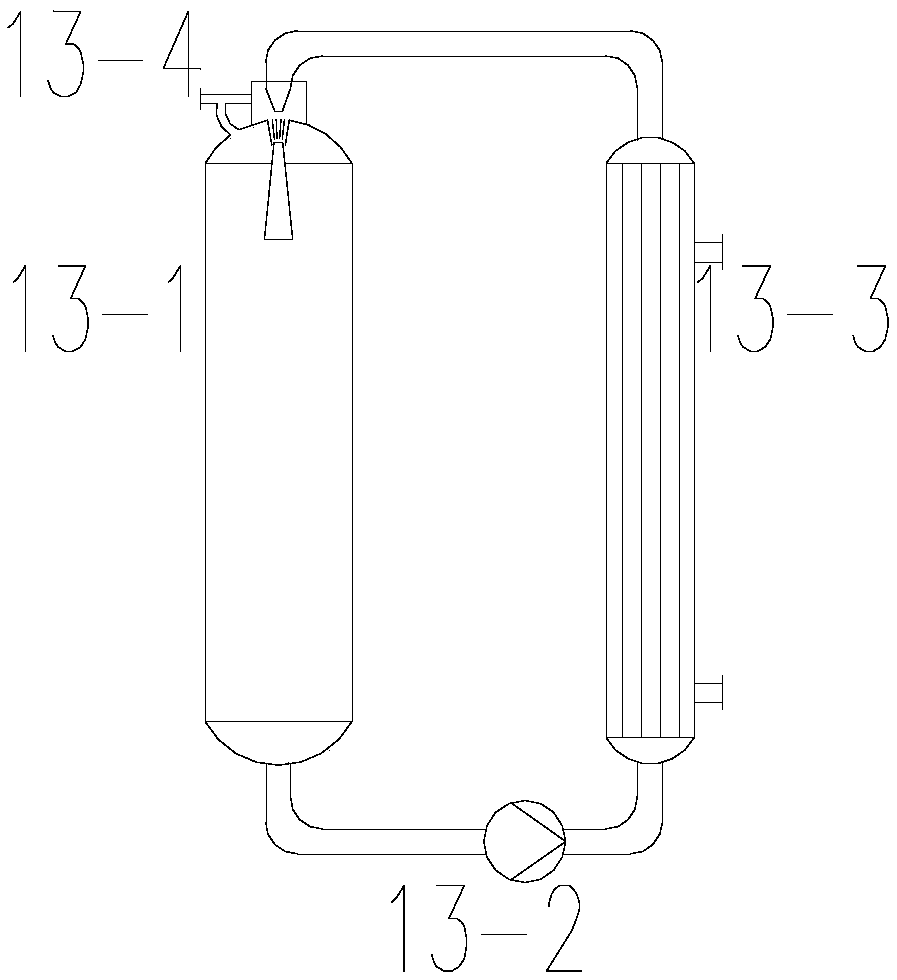

Continuous device for preparing benzaldehyde midbody and application thereof

PendingCN108892616ALarge specific surface areaSmall working volumeLithium organic compoundsOrganic compound preparationLithiumProduct system

The invention provides a continuous device for preparing a benzaldehyde midbody and application thereof. The continuous device comprises a continuous lithiation reaction device and a continuous formylation device. The continuous lithiation reaction device is provided with a first feeding inlet and a first discharging outlet, the first feeding inlet is used for adding a reaction raw material and anorganic lithium reagent, and the first discharging outlet is used for continuously discharging a product system obtained after a continuous lithiation reaction; the continuous formylation device is provided with a second feeding inlet, a formylation reagent inlet and a second discharging outlet, the second feeding inlet and the first discharging outlet are communicated so that the product systemobtained after the continuous lithiation reaction can be continuously conveyed into the continuous formylation device, the formylation reagent inlet is used for adding a formylation reagent, and the second discharging outlet is used for continuously discharging the product system obtained after the continuous formylation reaction. By adopting the device, the reaction selectivity is improved, energy consumption is lowered, and meanwhile industrial production is facilitated.

Owner:ASYMCHEM LIFE SCI TIANJIN

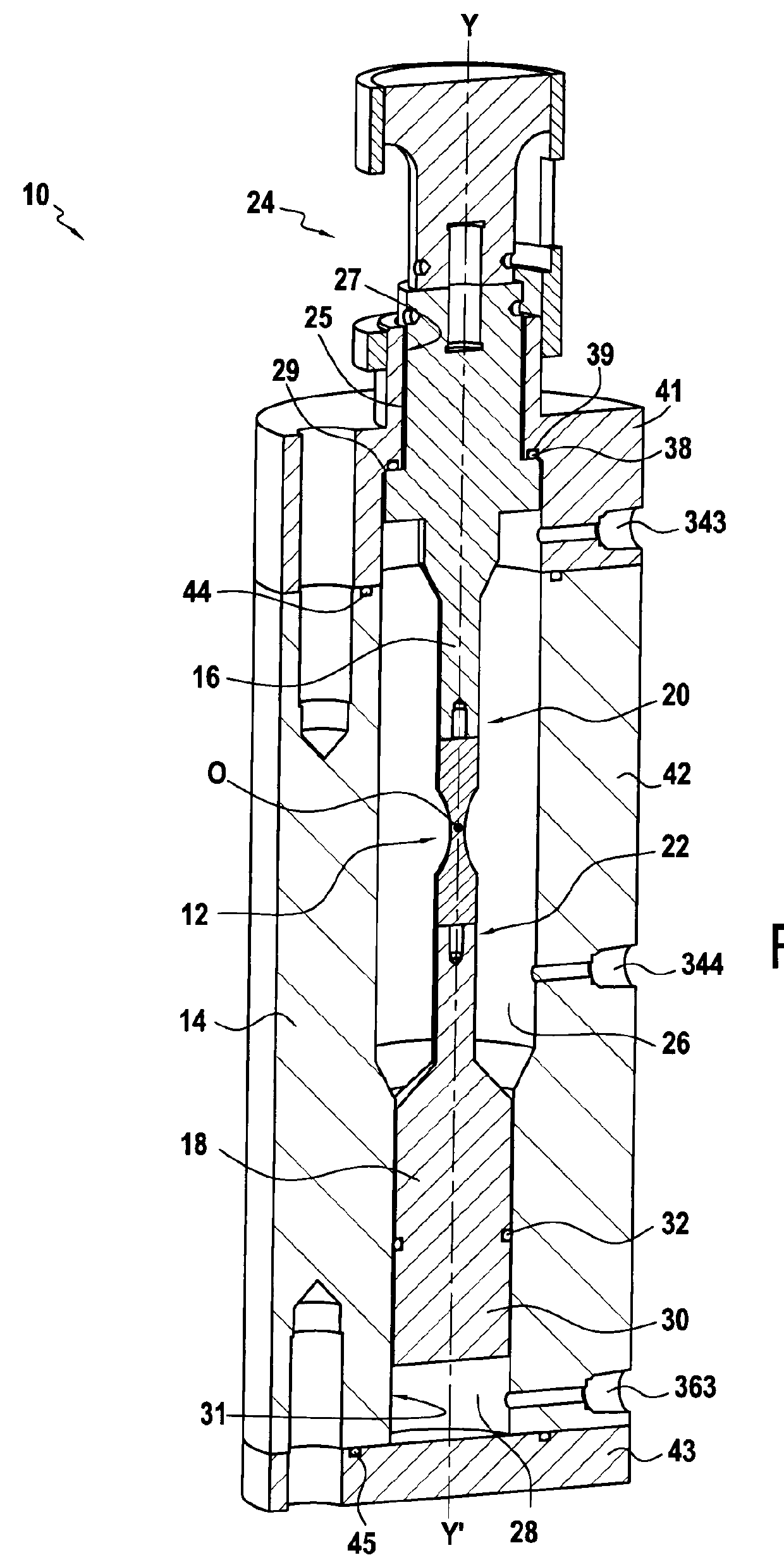

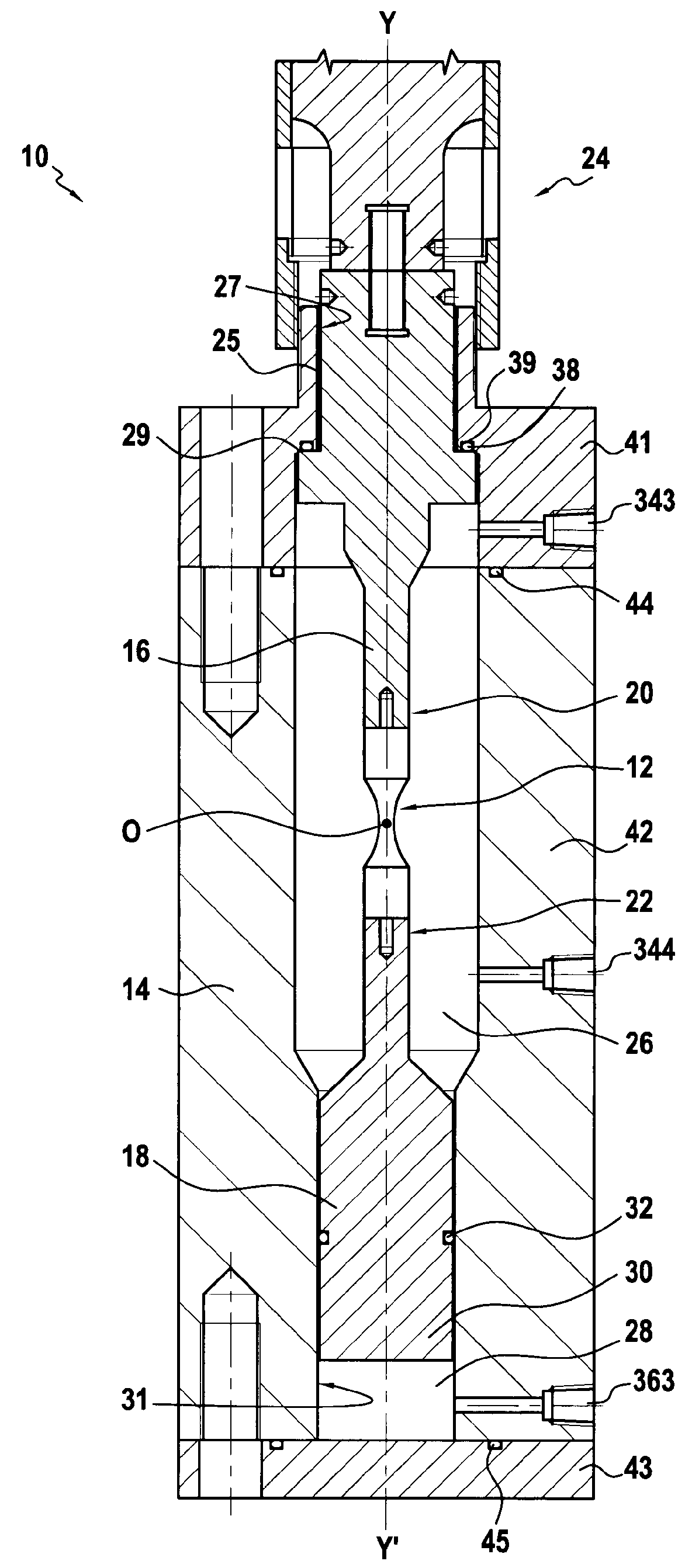

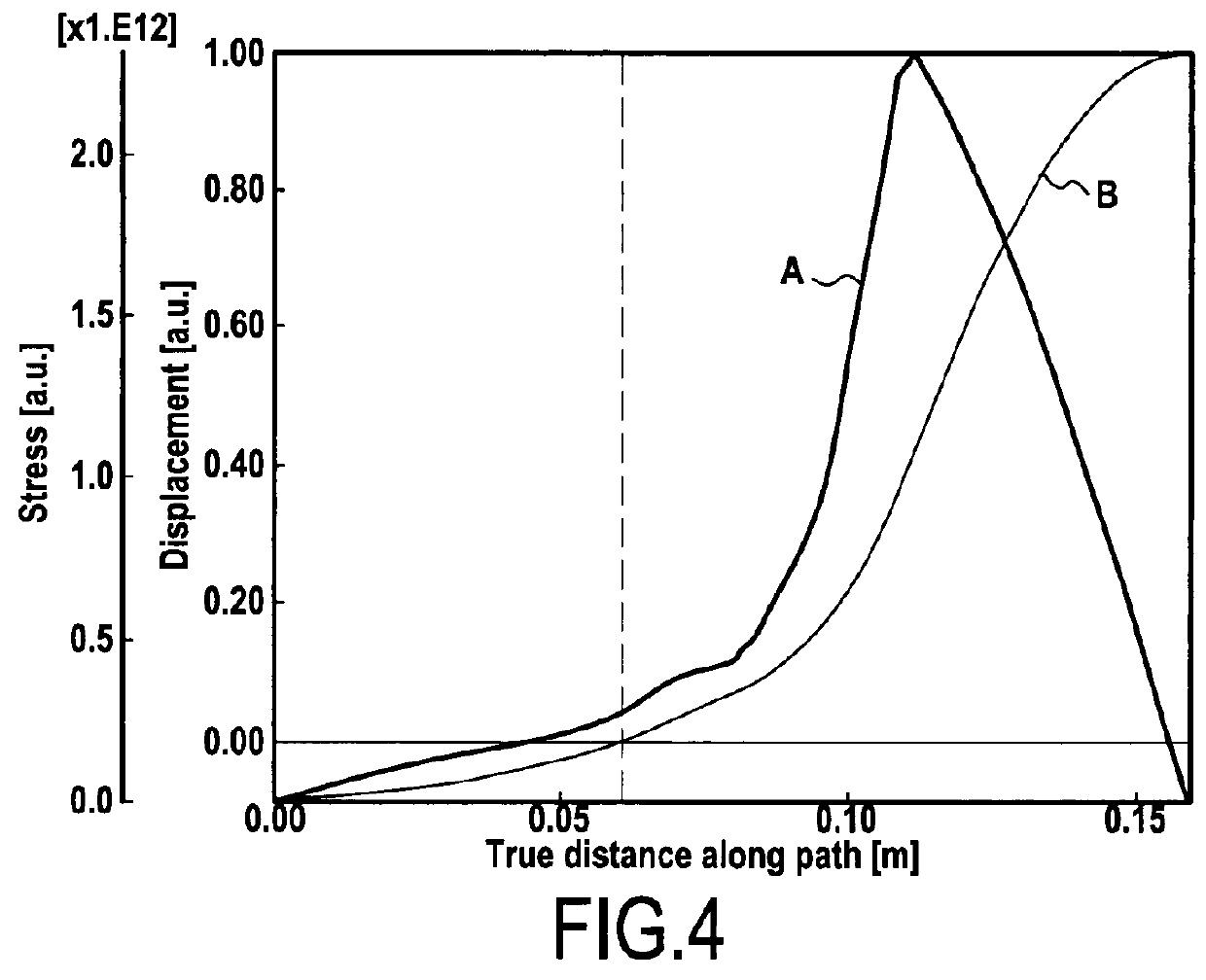

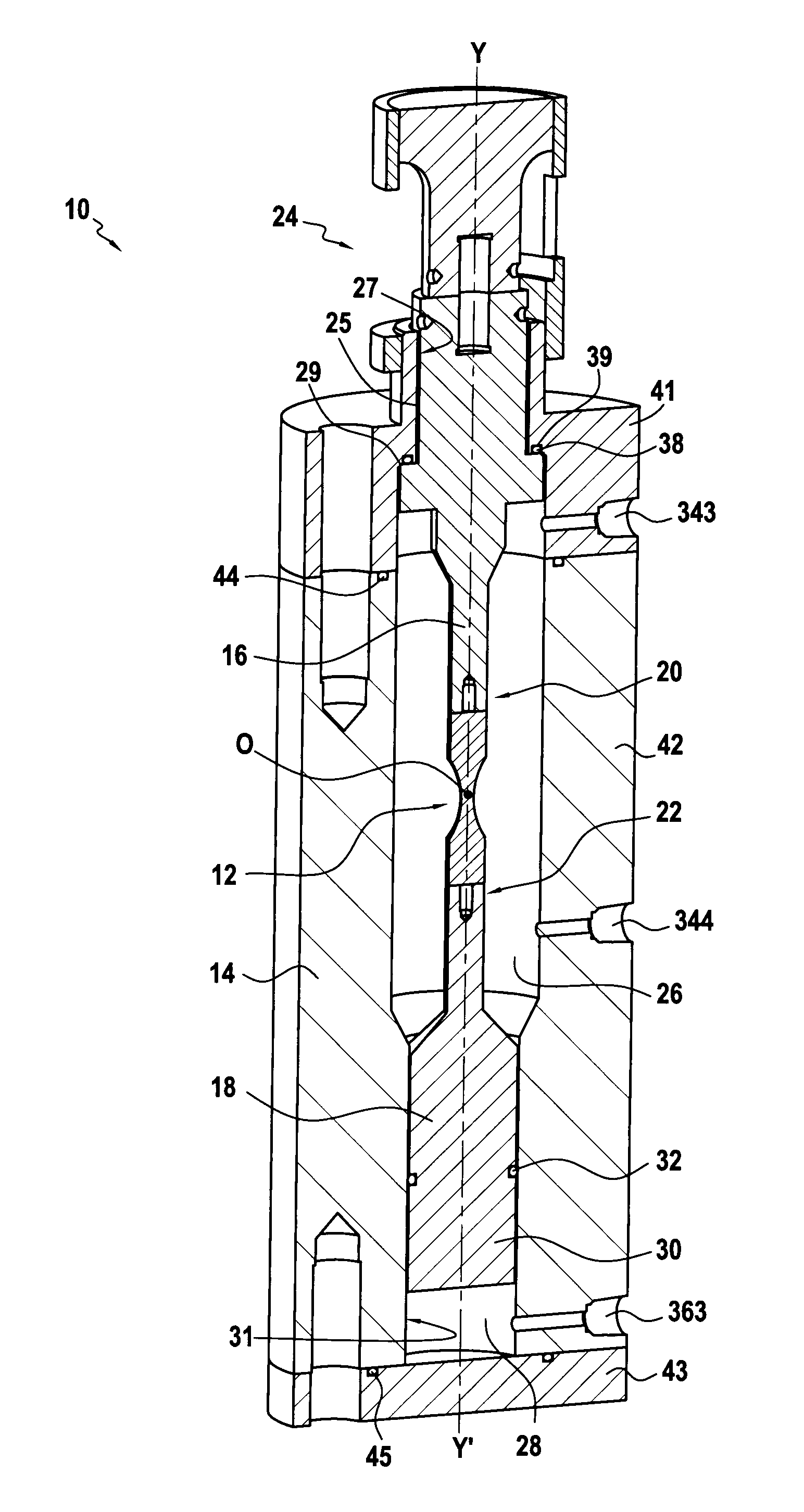

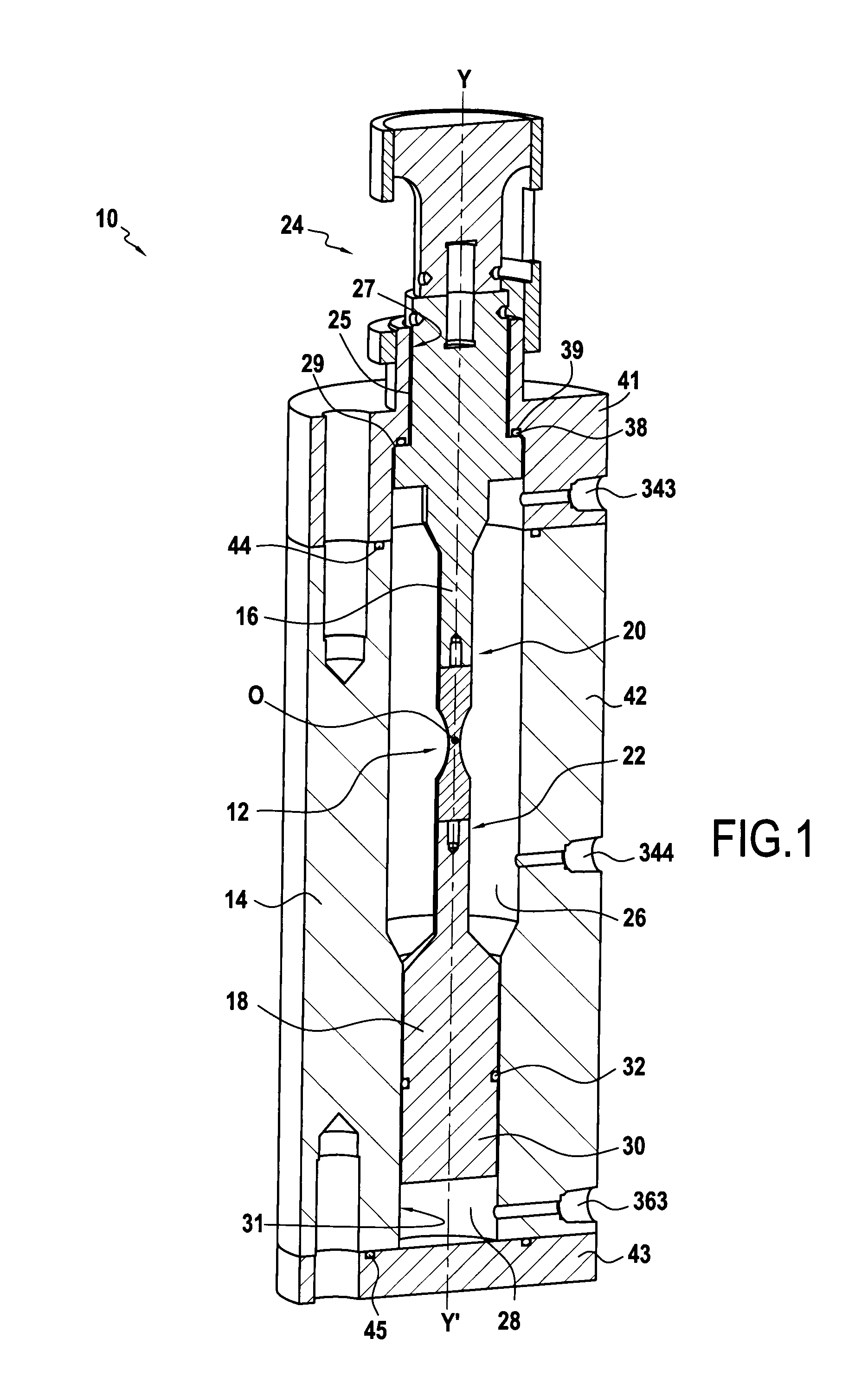

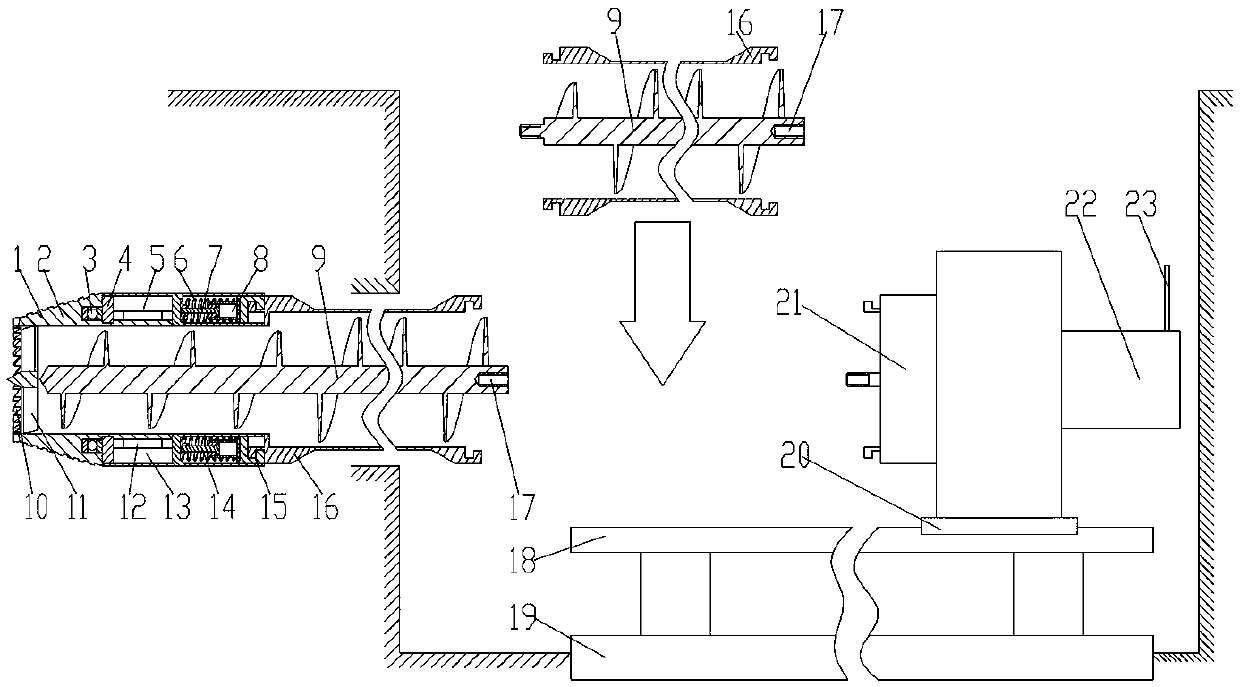

Apparatus and method for carrying out in a controlled atmosphere material fatigue tests in a high cycle regime with a controlled strain ratio

ActiveUS9383303B2Small working volumeReduce riskMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesEngineeringHigh pressure

An apparatus for carrying out high cycle fatigue tests of a specimen under high pressure, including: a pressure vessel; a load train including a first horn and a second horn between which a specimen is to be arranged, wherein the load train is arranged within an internal chamber of the pressure vessel; and a converter configured to apply ultrasonic waves into the load train by exciting the first horn to apply a dynamic stress to the specimen. A base part of the second horn is movably seated in the pressure vessel such that two separated chambers are formed within the pressure vessel with the first chamber for the specimen, wherein both chambers can be fed with gas and charged with different gas pressures in order to apply a static stress to the specimen.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Apparatus and method for carrying out in a controlled atmosphere material fatigue tests in a high cycle regime with a controlled strain ratio

ActiveUS20140245833A1Small working volumeImprove securityMaterial analysis using sonic/ultrasonic/infrasonic wavesMaterial strength using tensile/compressive forcesEngineeringHigh pressure

An apparatus for carrying out high cycle fatigue tests of a specimen under high pressure, including: a pressure vessel; a load train including a first horn and a second horn between which a specimen is to be arranged, wherein the load train is arranged within an internal chamber of the pressure vessel; and a converter configured to apply ultrasonic waves into the load train by exciting the first horn to apply a dynamic stress to the specimen. A base part of the second horn is movably seated in the pressure vessel such that two separated chambers are formed within the pressure vessel with the first chamber for the specimen, wherein both chambers can be fed with gas and charged with different gas pressures in order to apply a static stress to the specimen.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

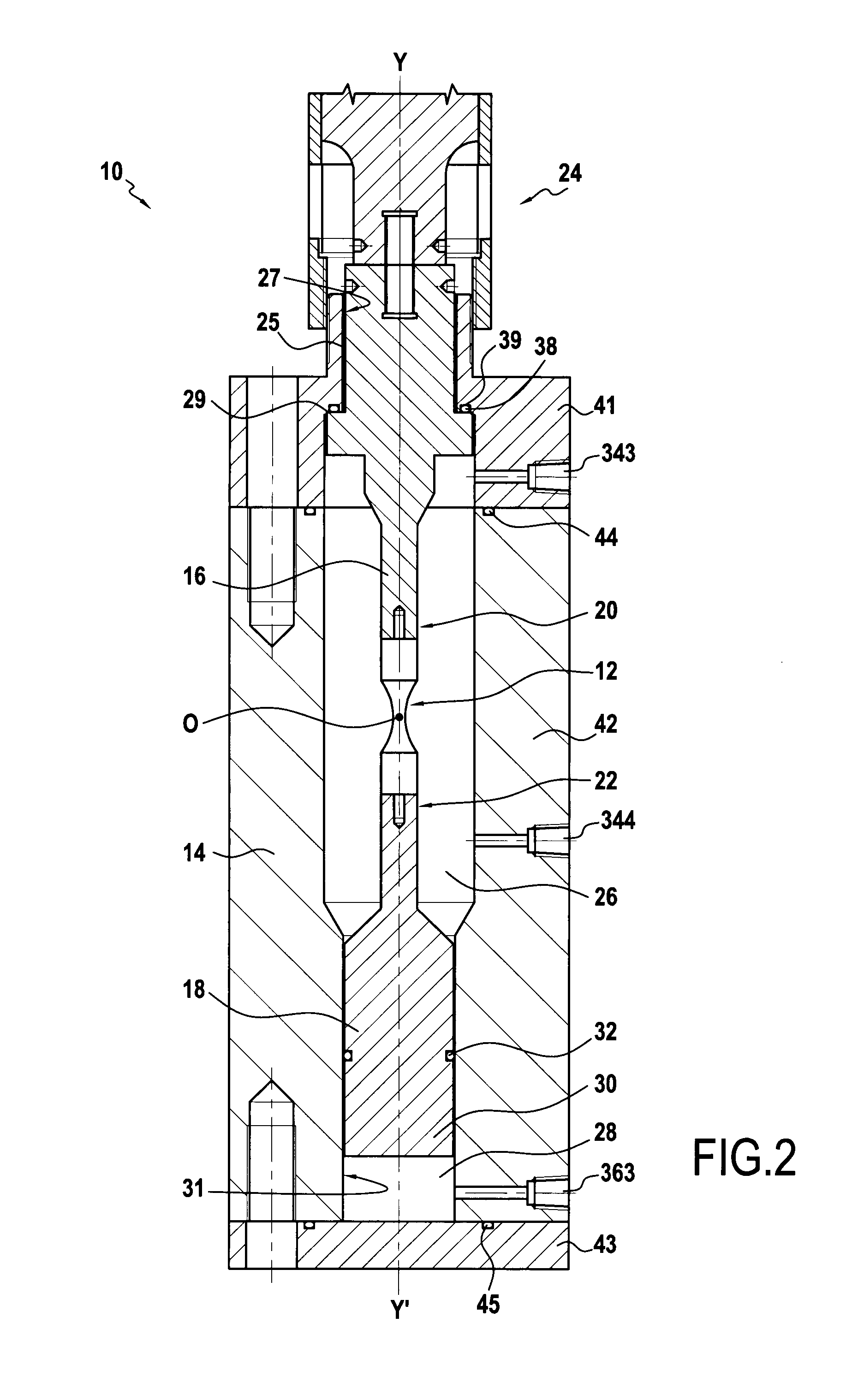

Method for preparing triallyl isocyanurate

InactiveCN101125832ASmall working volumeShort stayOrganic chemistryIsomerizationTriallyl isocyanurate

The invention relates to an improved method which can be safely implemented for producing triallyl isocyanurate (TAIC) through the rearrangement function and under at least a temperature below 90 DEG C through triallyl cyanurate (AIC) which is catalyzed by Cu2+. According to the invention, TAC and arbitrarily selected Cu2+ catalyst and solvent are added constantly into the original reaction mixture after the beginning of previously inhibited isomerization, and the isomerization is implemented at the temperature of 90-160 DEG C, and an equal amount to the amount of the original reactants of reaction mixture is extracted continuously and purified. The isomerization is implemented in TAIC which is preferentially chosen as a reaction medium.

Owner:DEGUSSA AG

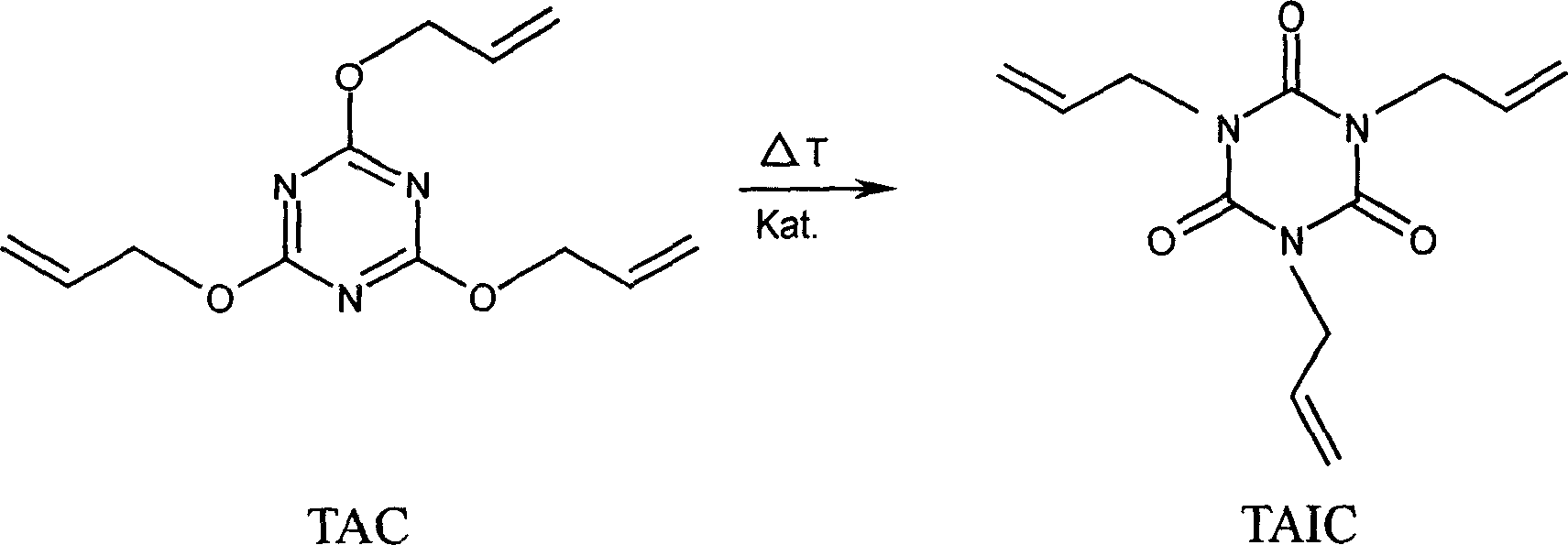

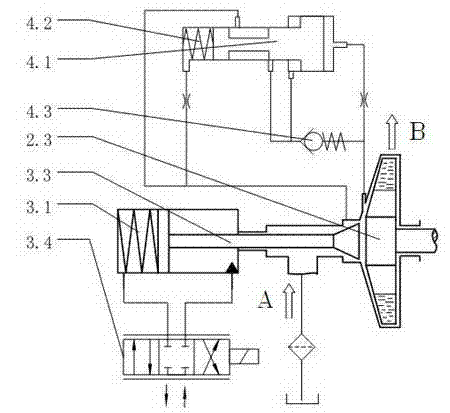

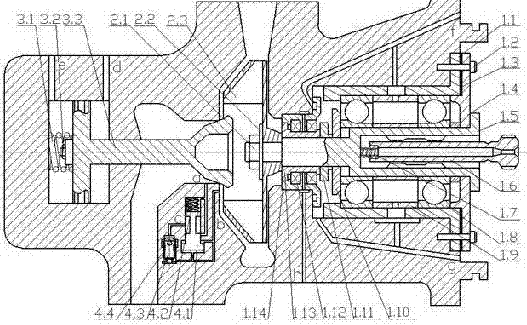

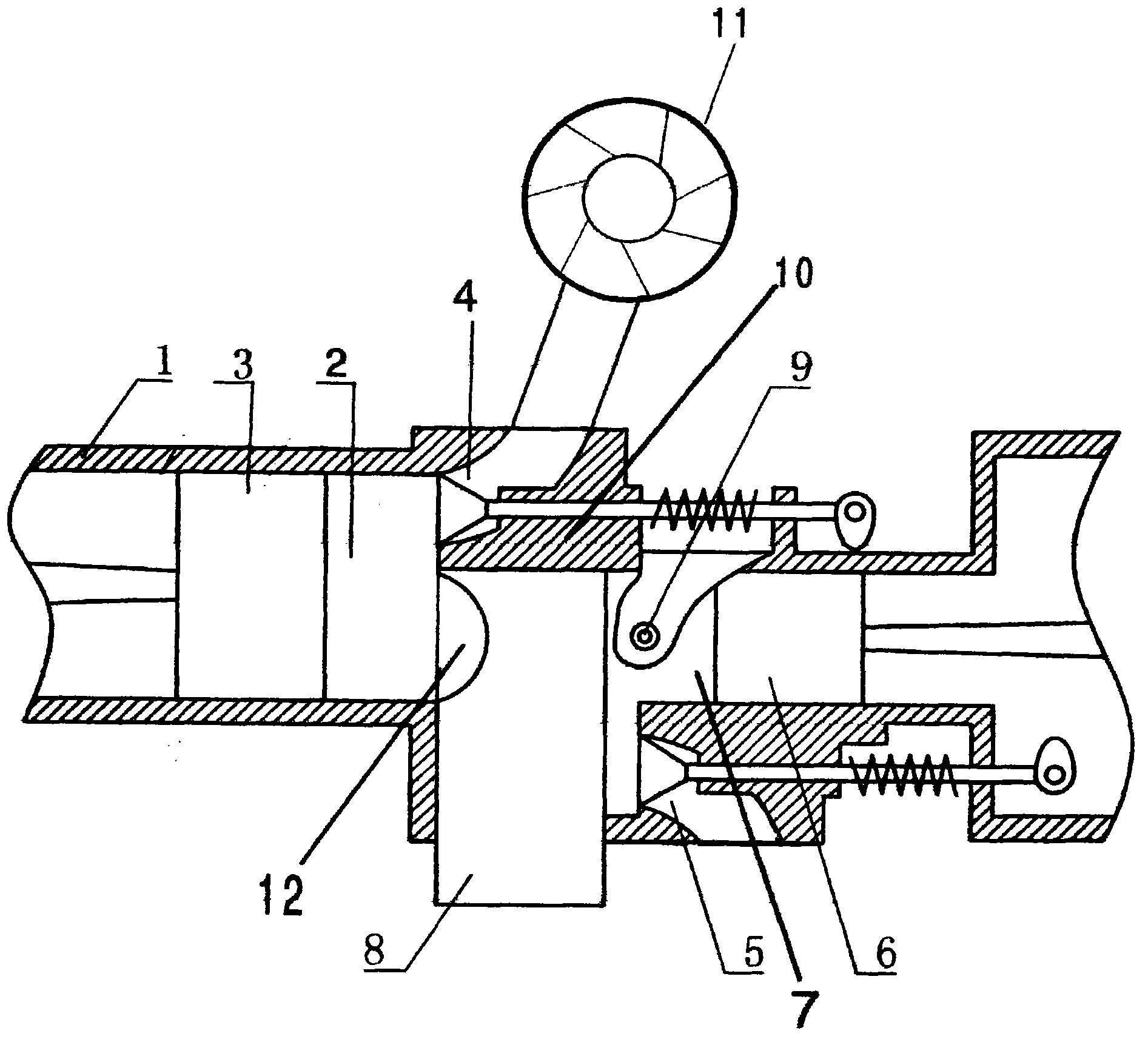

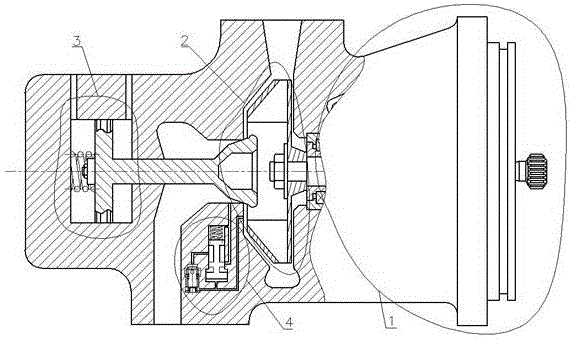

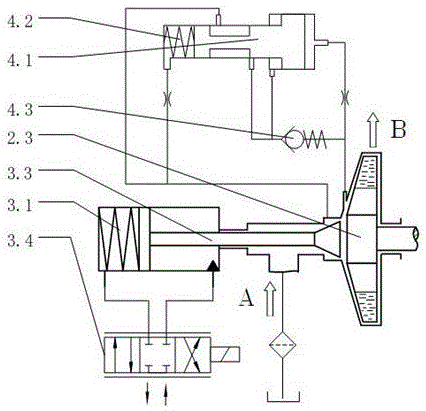

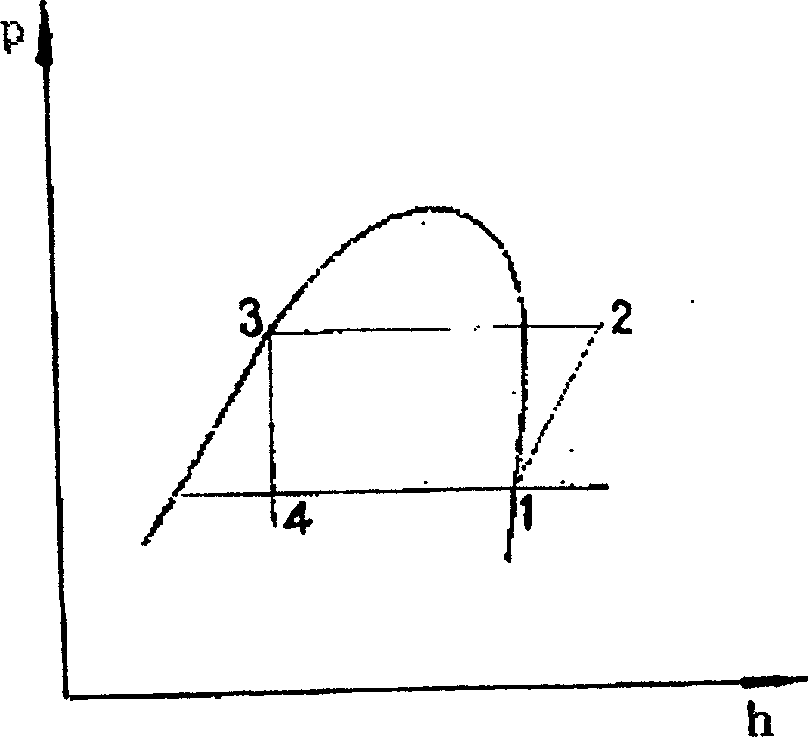

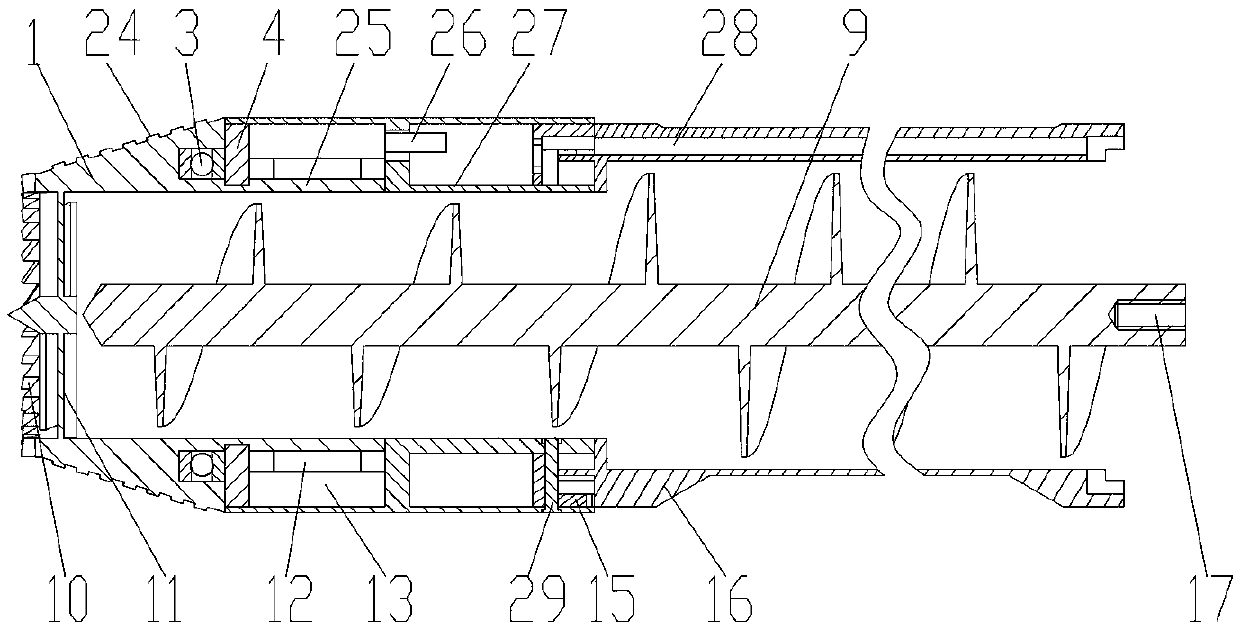

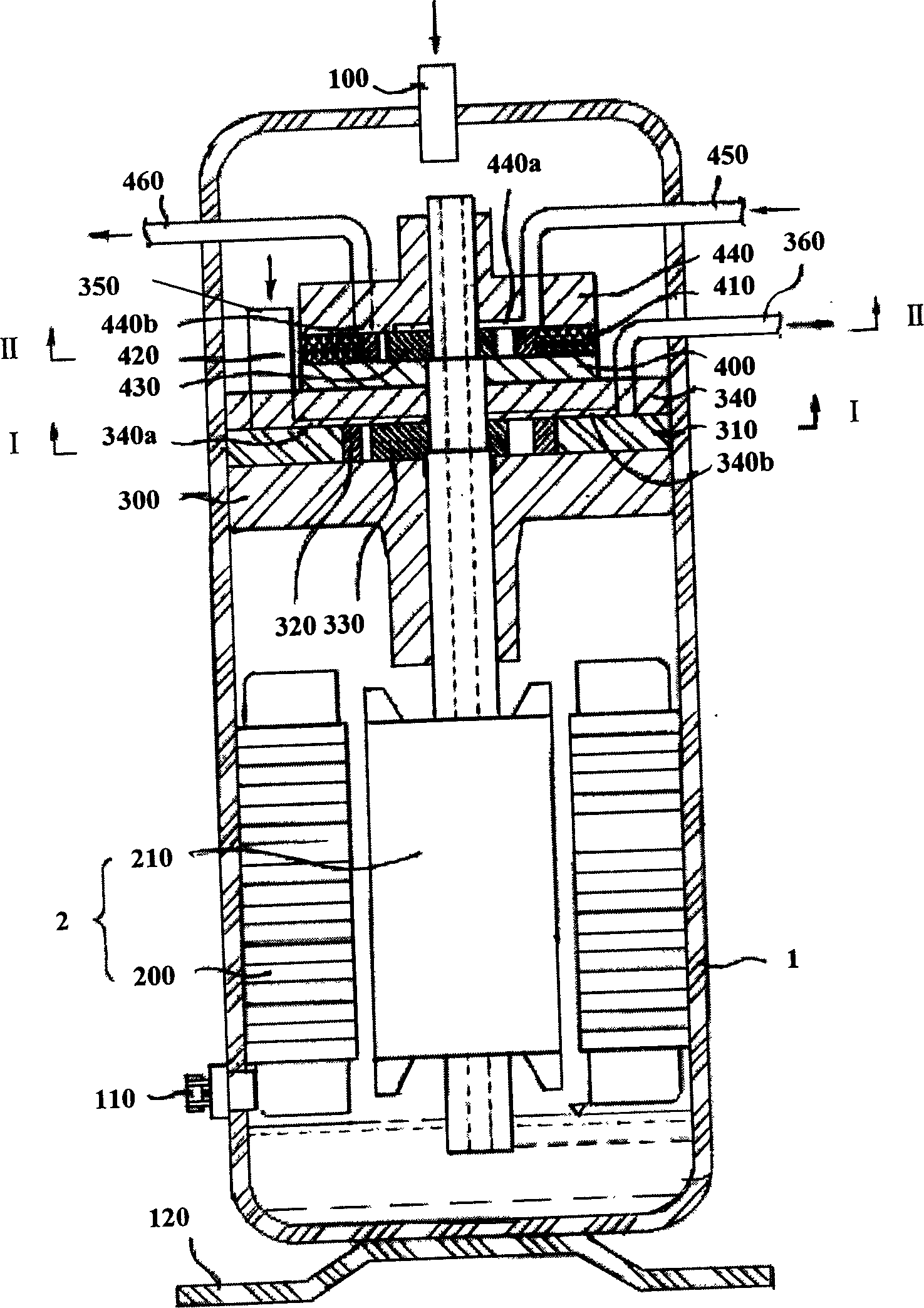

Vapor-core pump with impeller central pressure supplement regulator

ActiveCN103206383AAvoid or suppress cavitationAvoid or suppress harmSpecific fluid pumpsPump componentsImpellerCavitation

The invention provides a vapor-core pump with an impeller central pressure supplement regulator. The impeller central pressure supplement regulator enables the vapor-core pump to operate under higher performance and efficiency. By the aid of the impeller central pressure supplement regulator for controlling front and back pressures at a valve port of an inlet throttle valve, cavitation caused by excessively low central impeller pressure can be avoided or inhibited effectively, and the damage caused by cavitation can also be avoided.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Intracellular delivery

ActiveCN107058101ARestrict/Eliminate FunctionShorten the timeBioreactor/fermenter combinationsBiological substance pretreatmentsCell membraneMicrofluidic channel

A microfluidic system for causing perturbations in a cell membrane, the system including a microfluidic channel defining a lumen and being configured such that a cell suspended in a buffer can pass therethrough, wherein the microfluidic channel includes a cell-deforming constriction, wherein a diameter of the constriction is a function of the diameter of the cell.

Owner:MASSACHUSETTS INST OF TECH

Repeated pressure boosting internal combustion engine

InactiveCN103511062AImprove air tightnessIncrease the compression ratioInternal combustion piston enginesLow speedTurbocharger

The invention relates to an internal combustion engine and provides a repeated pressure boosting internal combustion engine which can separately complete an energy conversion process and is high in energy utilization efficiency, low in fuel consumption rate and high in speed, torque and power. According to the main principle of the repeated pressure boosting internal combustion engine, the suction process, the compression process, the acting process and the exhaust process are separately conducted in two air cylinders which are different in size, effective pressure in the air cylinders is increased at the time of acting through self structures, as a result, the combustion process is improved, and thermal efficiency is also improved; moreover, matched with a turbocharger, a compression air cylinder 2 can suck in more air in a high speed stage to support the combustion of fuel. The repeated pressure boosting internal combustion engine has the advantages of being simple in structure, high in thermal efficiency, wide in operation adjustable range, low in oil consumption, good in acceleration performance, sufficient in power at a low speed, and strong in power at a high speed; moreover, acting frequency is doubled, the rotating speed range is substantially expanded, and therefore vibrations are reduced; due to the supercharged effect after combustion, the combustion process is improved, the fuel can be combusted more sufficiently and thoroughly, and the emission performance is better.

Owner:赵强国

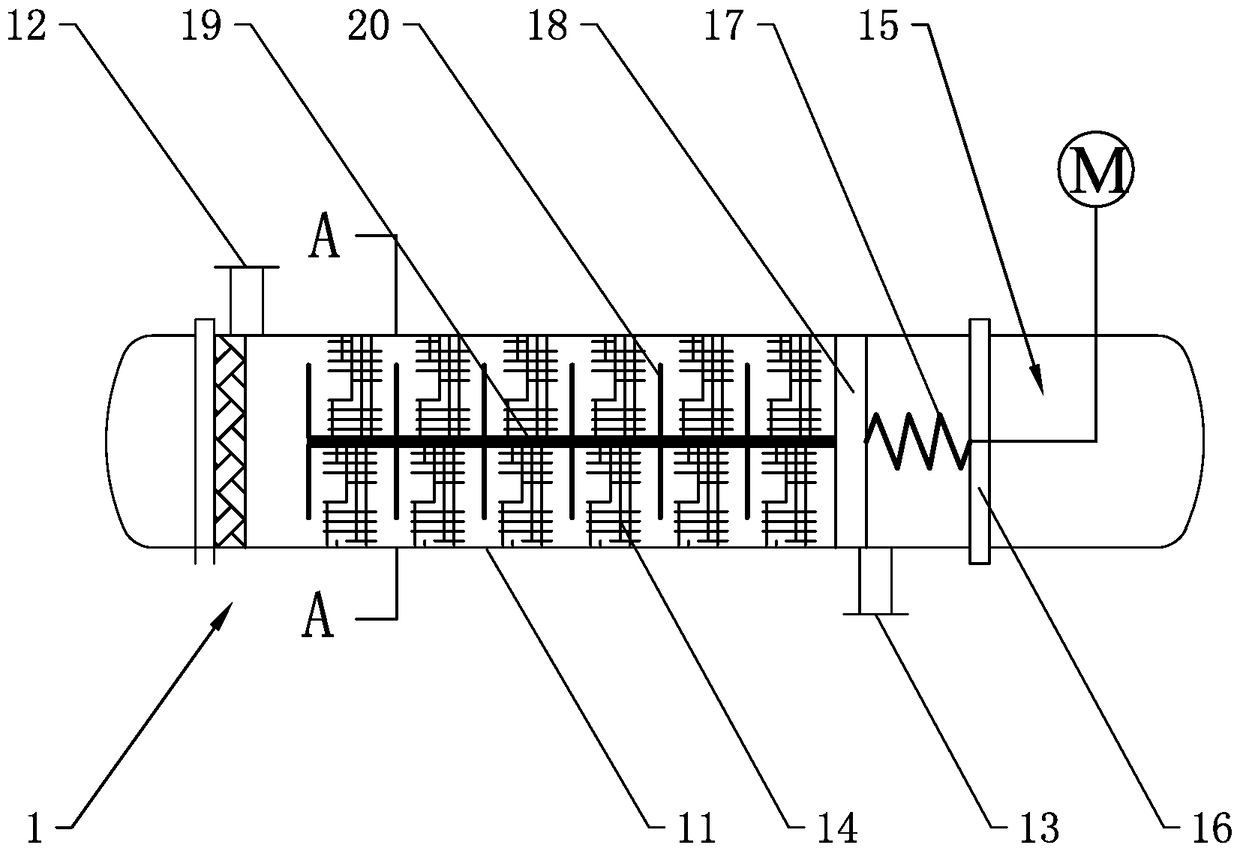

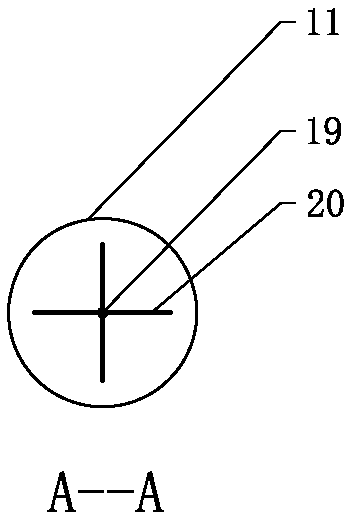

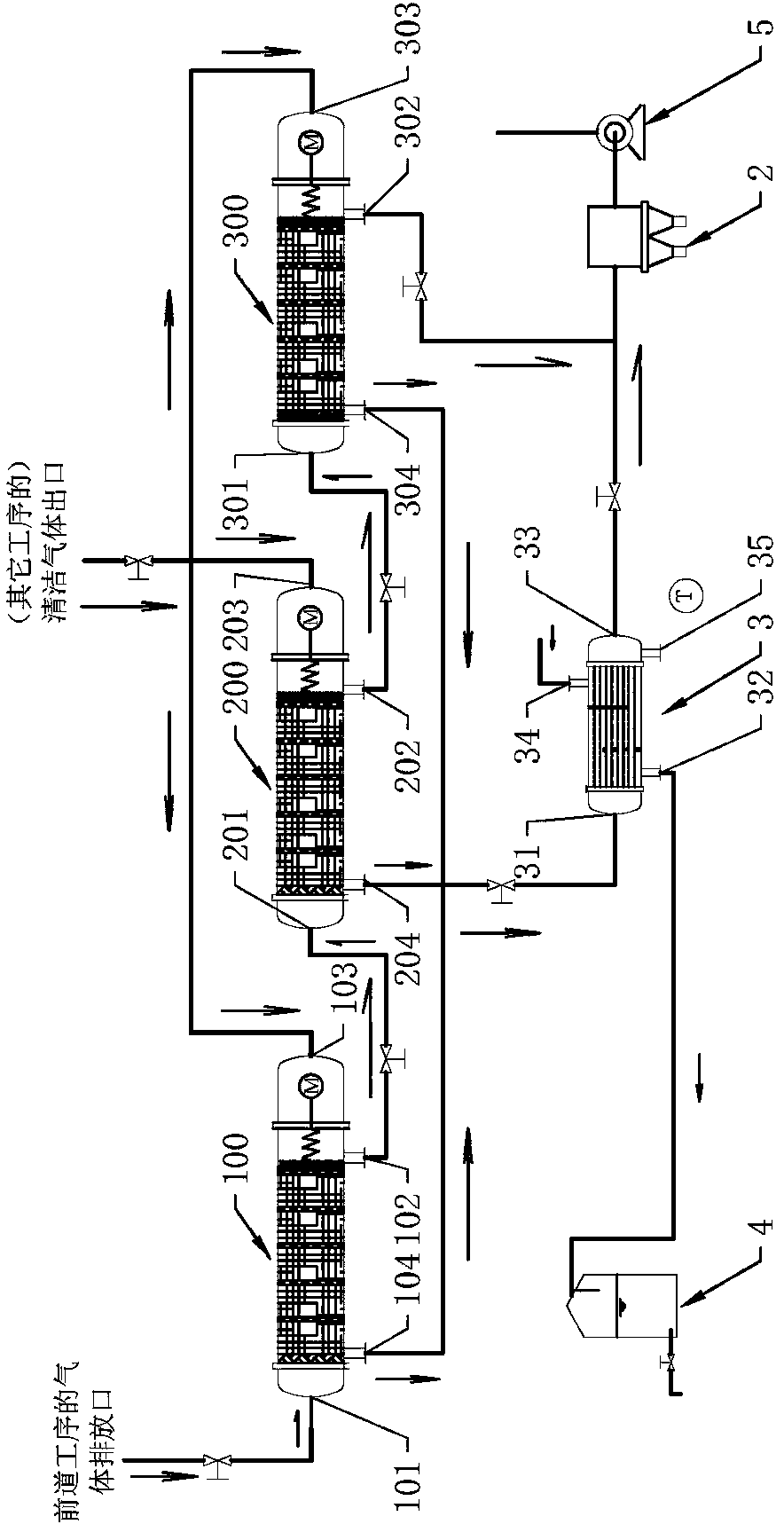

Adsorption reactor and method for separating high-boiling-point coagulable components from mixed gas

PendingCN108579332AMeet the needs of different adsorbatesMeet the needs of different operating conditionsGas treatmentDispersed particle separationFiberDesorption

The invention provides an adsorption reactor for separating high-boiling-point coagulable components from mixed gas. The adsorption reactor for separating the high-boiling-point coagulable componentsfrom the mixed gas comprises a columnar reactor shell, a front ventilating opening and a rear ventilating opening, and the front ventilating opening and the rear ventilating opening are separately formed in the two ends of the shell. The adsorption reactor for separating the high-boiling-point coagulable components from the mixed gas is characterized in that an ultra-fine fiber filler and a pressing device are arranged in the adsorption reactor, and the ultra-fine fiber filler is filled in the shell; and the pressing device comprises a driving unit and a pressure plate, and the driving unit drives the pressure plate to press or loosen the ultra-fine fiber filler. The invention simultaneously provides a method for separating the high-boiling-point coagulable components from the mixed gas. The method comprises the following steps: when adsorption operation is carried out, driving the pressure plate to press the ultra-fine fiber filler by the driving unit; when desorption operation is carried out, driving the pressure plate to move reversely by the driving unit, and loosening the ultra-fine fiber filler; and carrying out coagulation treatment on the desorbed gas to obtain adsorbed matters which are separated and recycled. The adsorption reactor for separating high-boiling-point coagulable components from mixed gas has the advantages of high adsorption efficiency, long adsorbent regeneration period, convenience in regeneration and flexibility in operation.

Owner:ZUNYI NORMAL COLLEGE

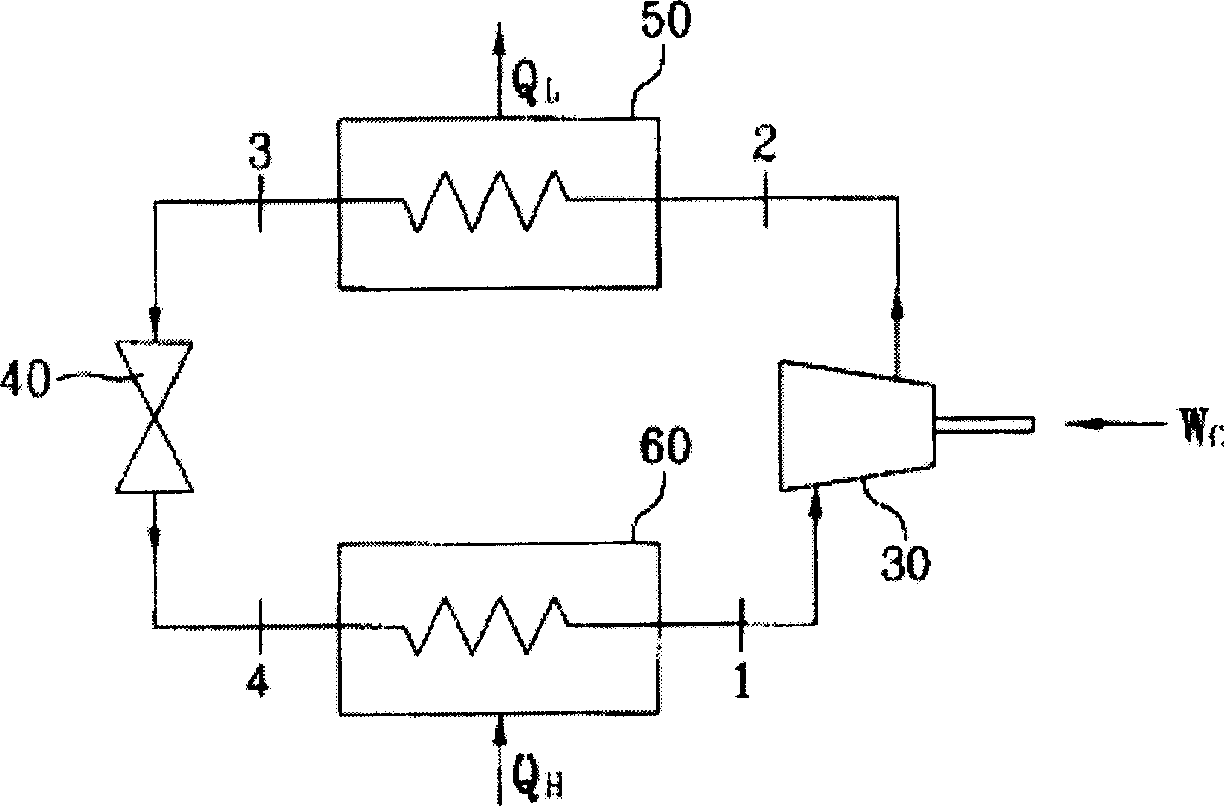

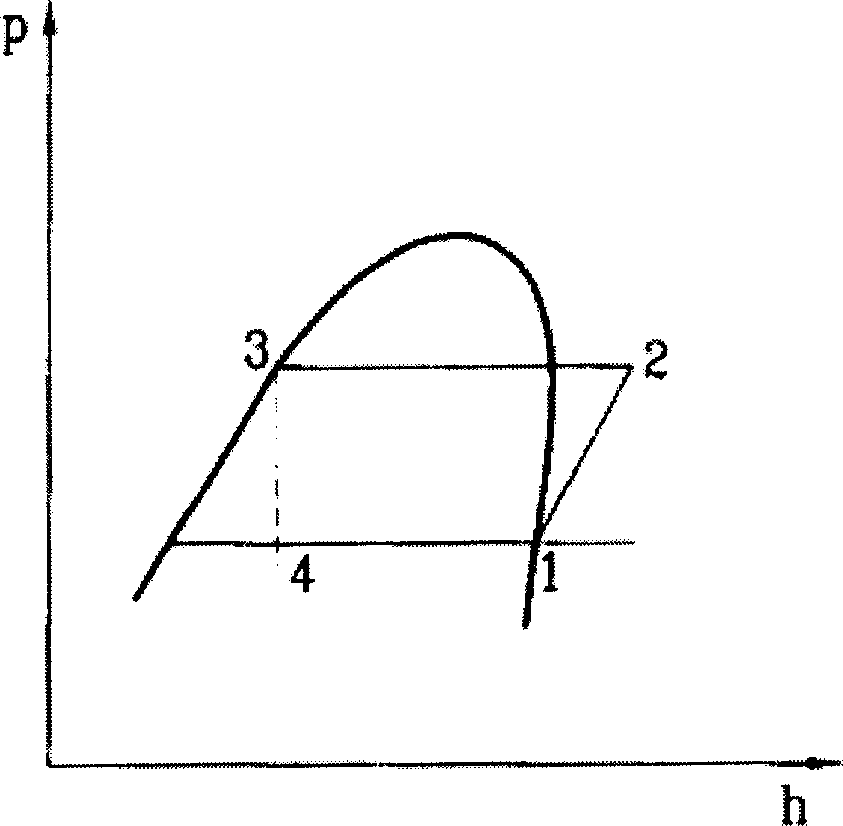

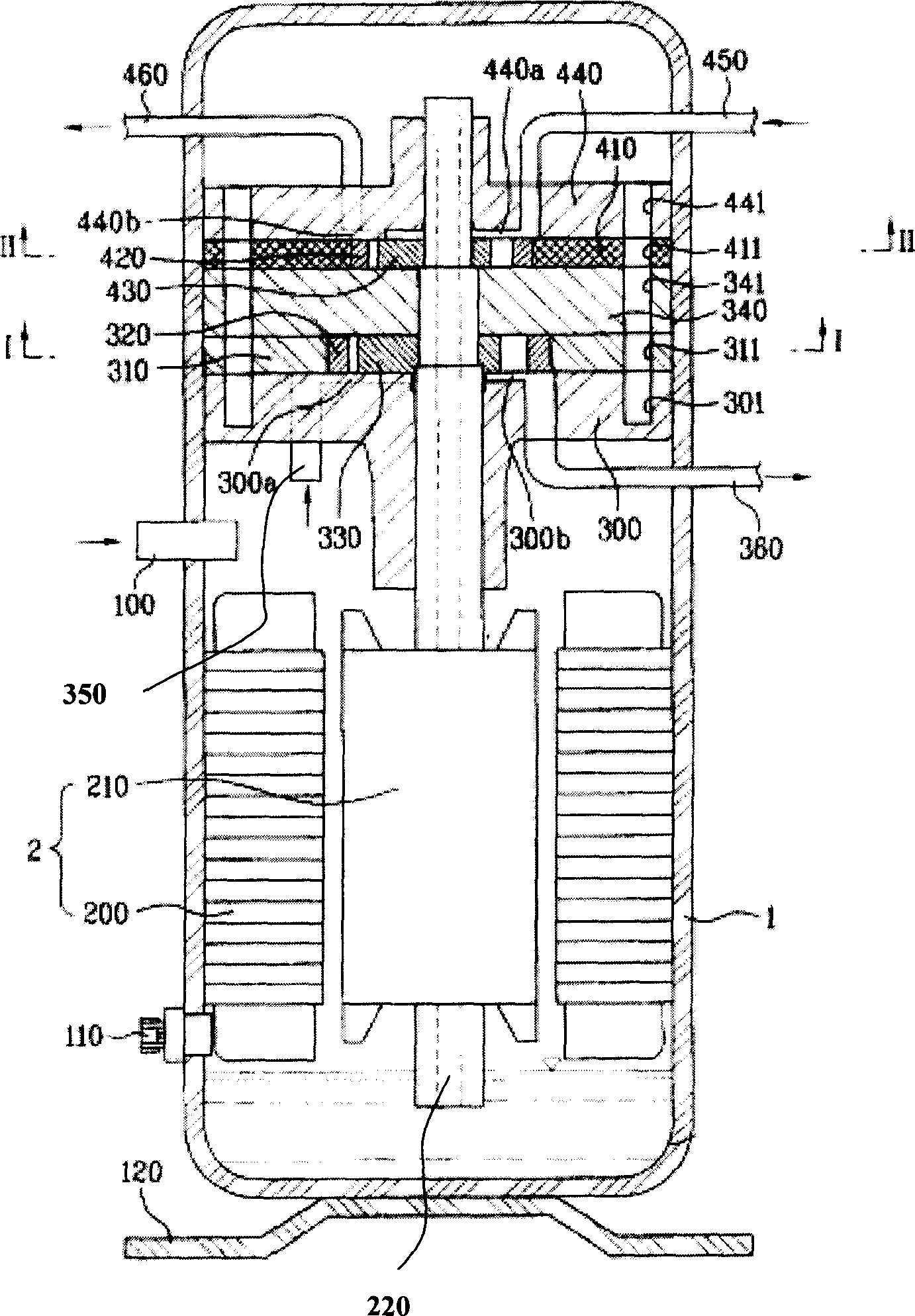

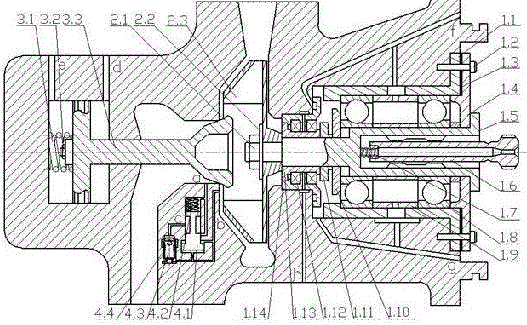

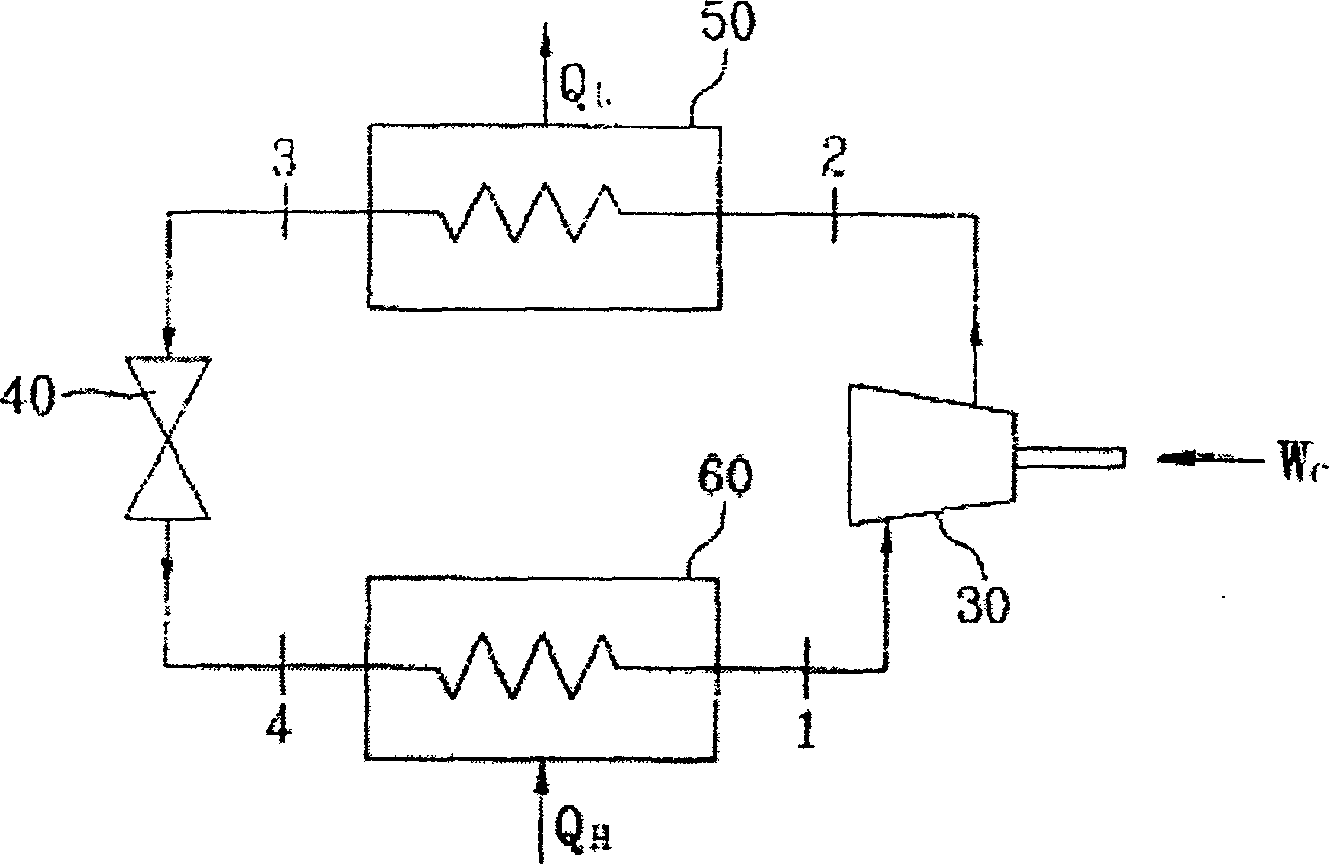

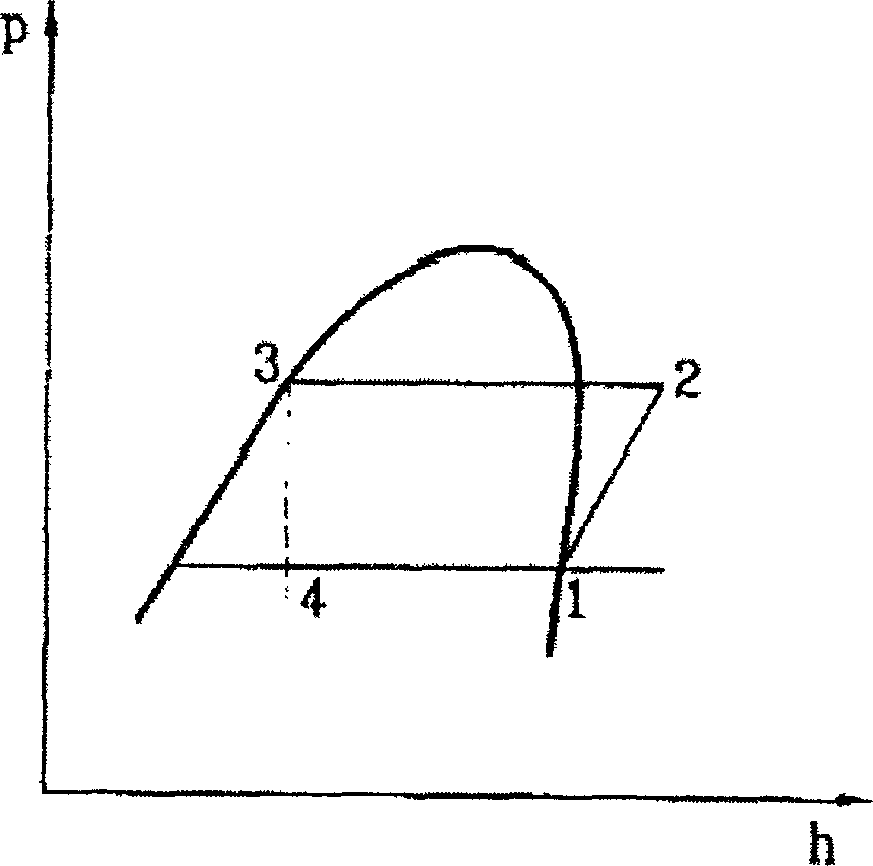

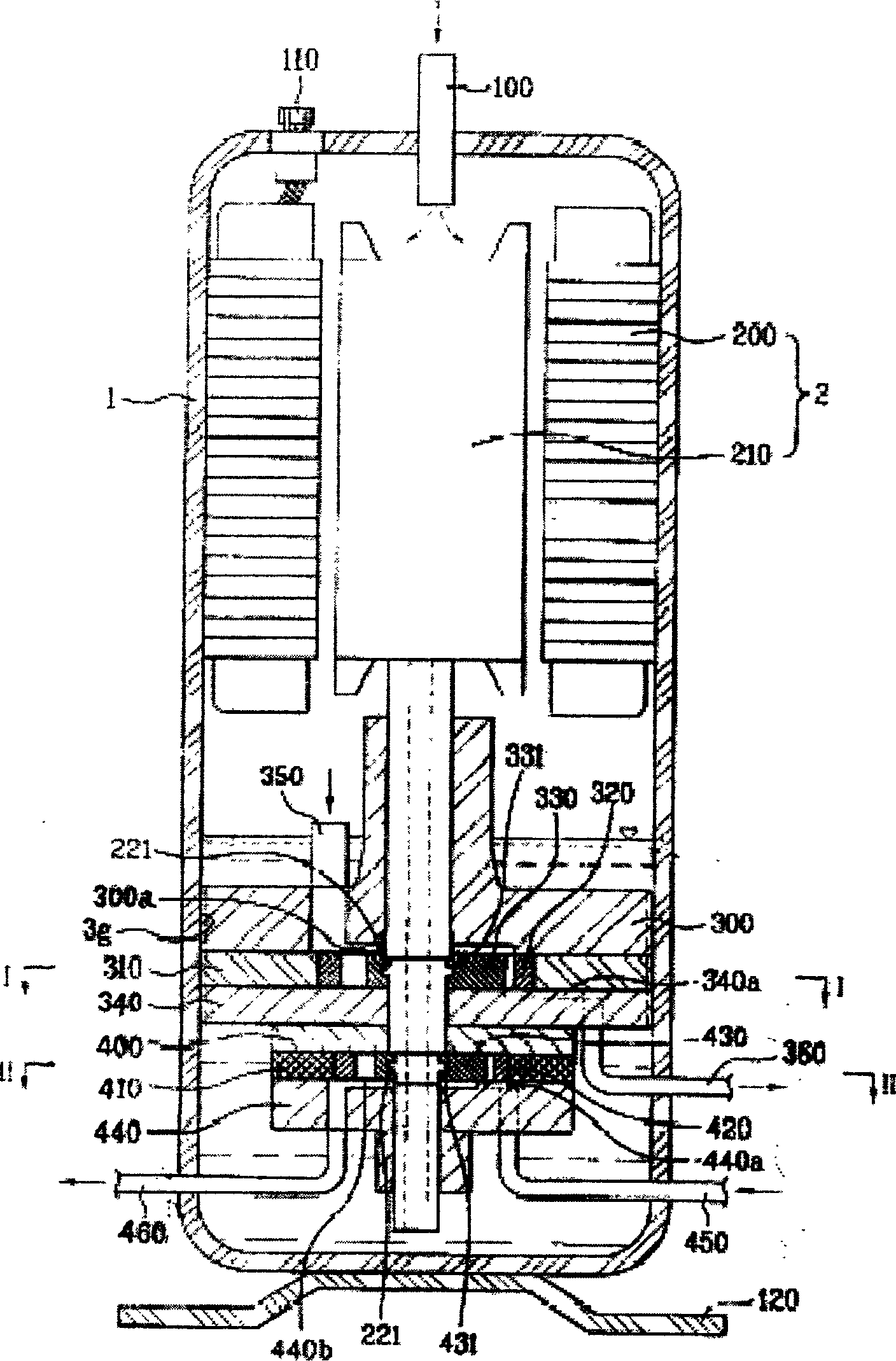

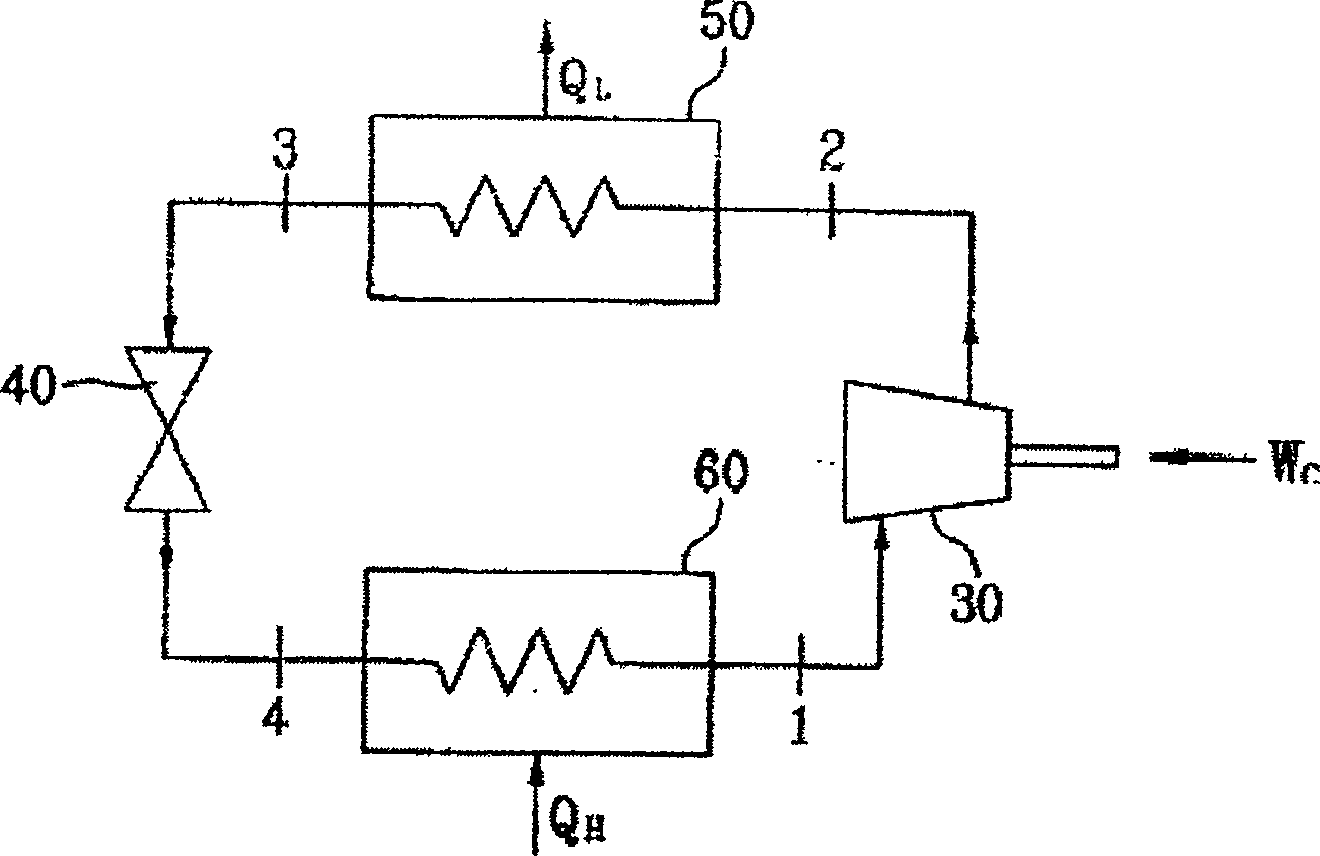

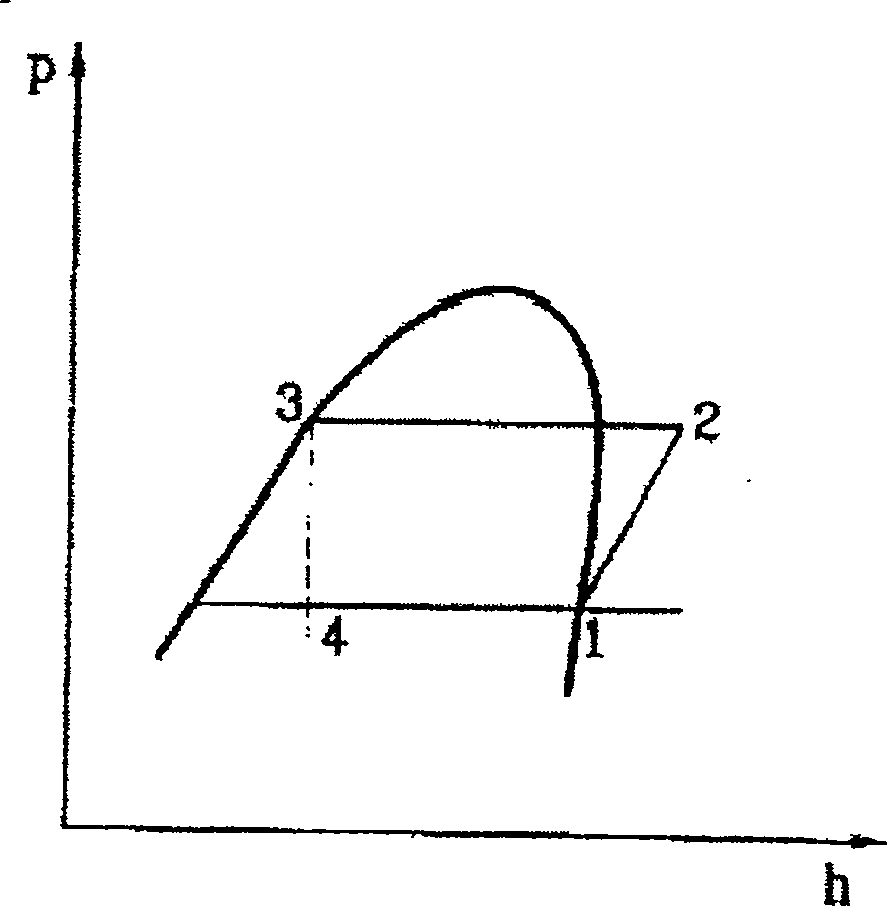

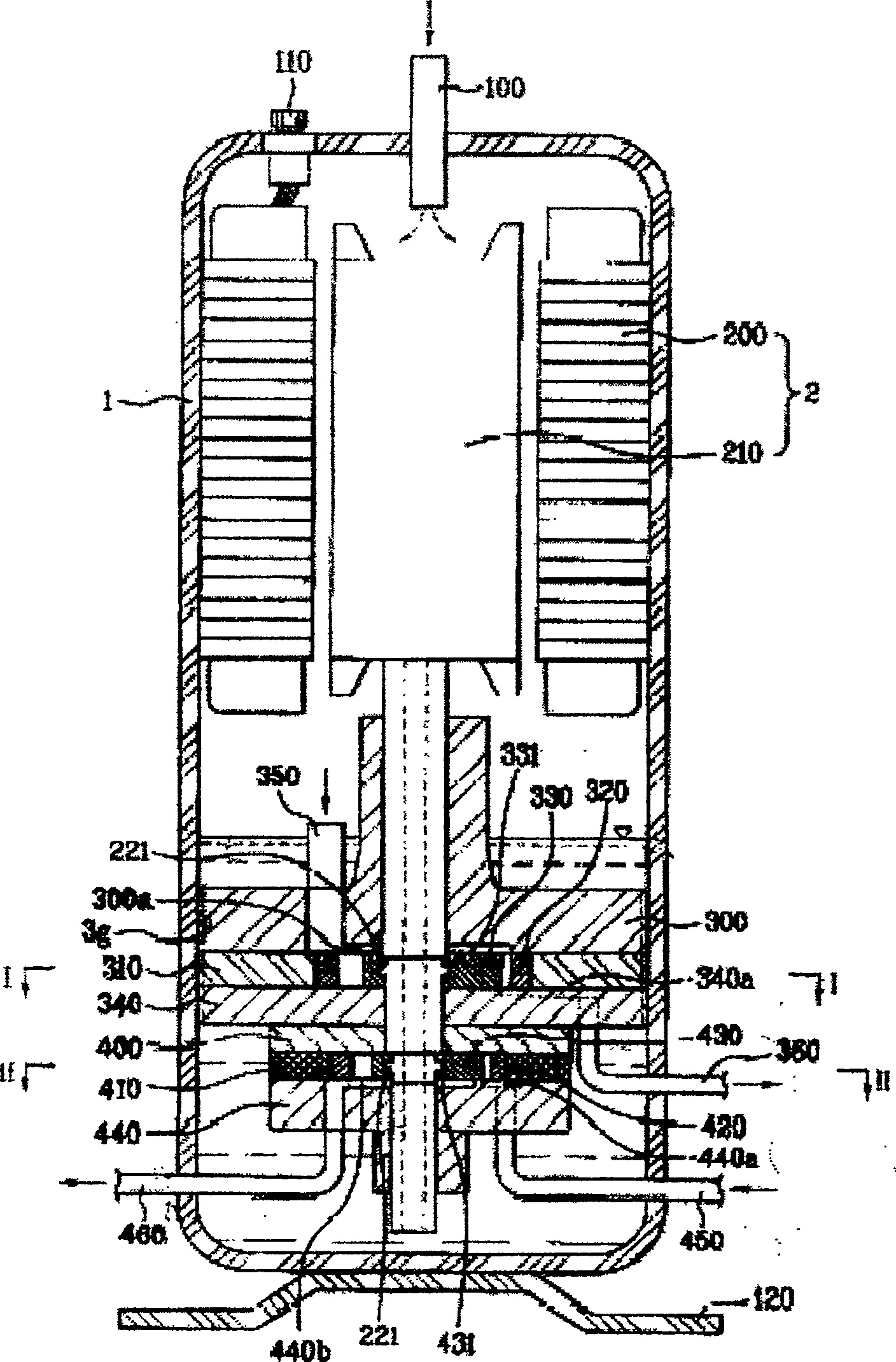

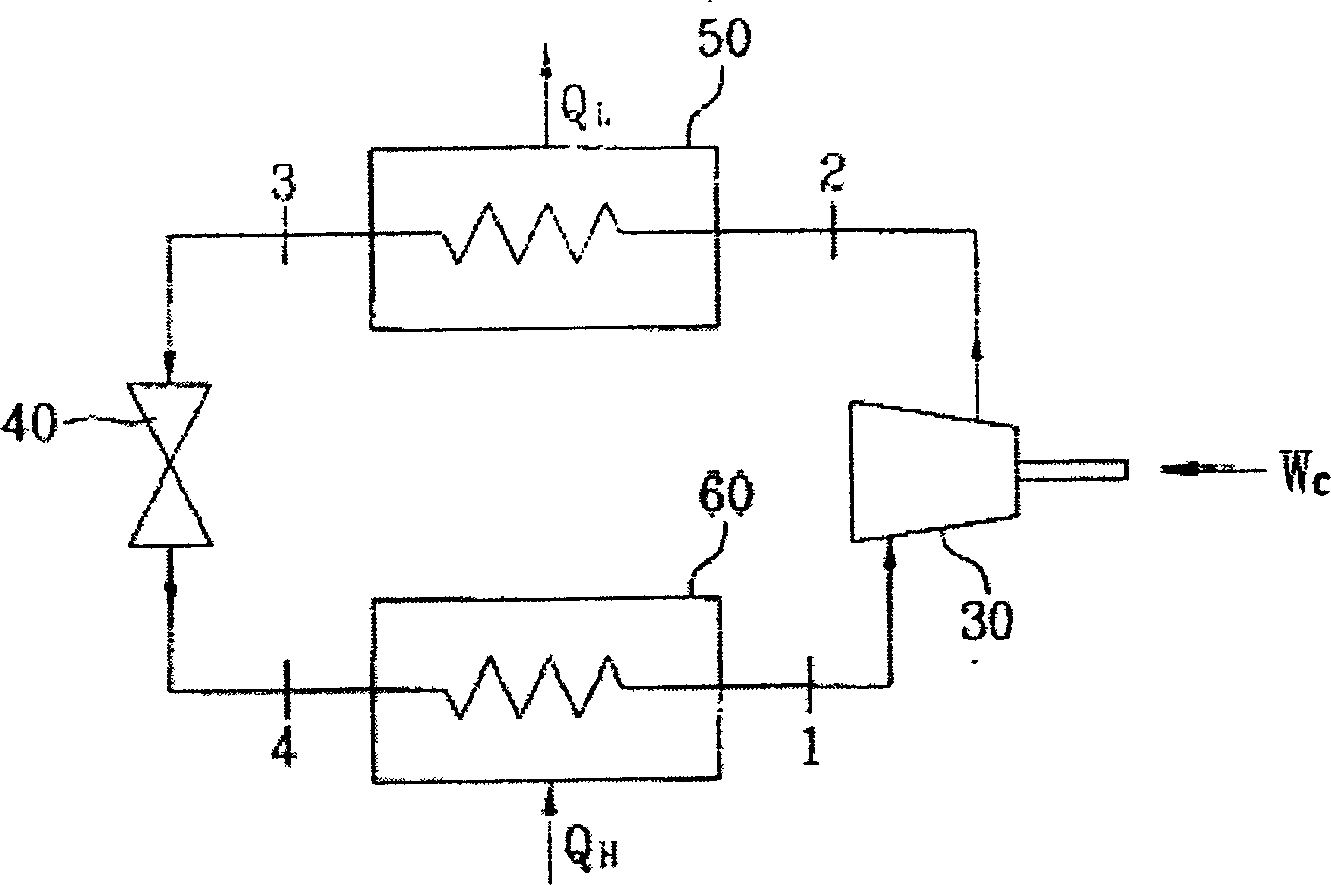

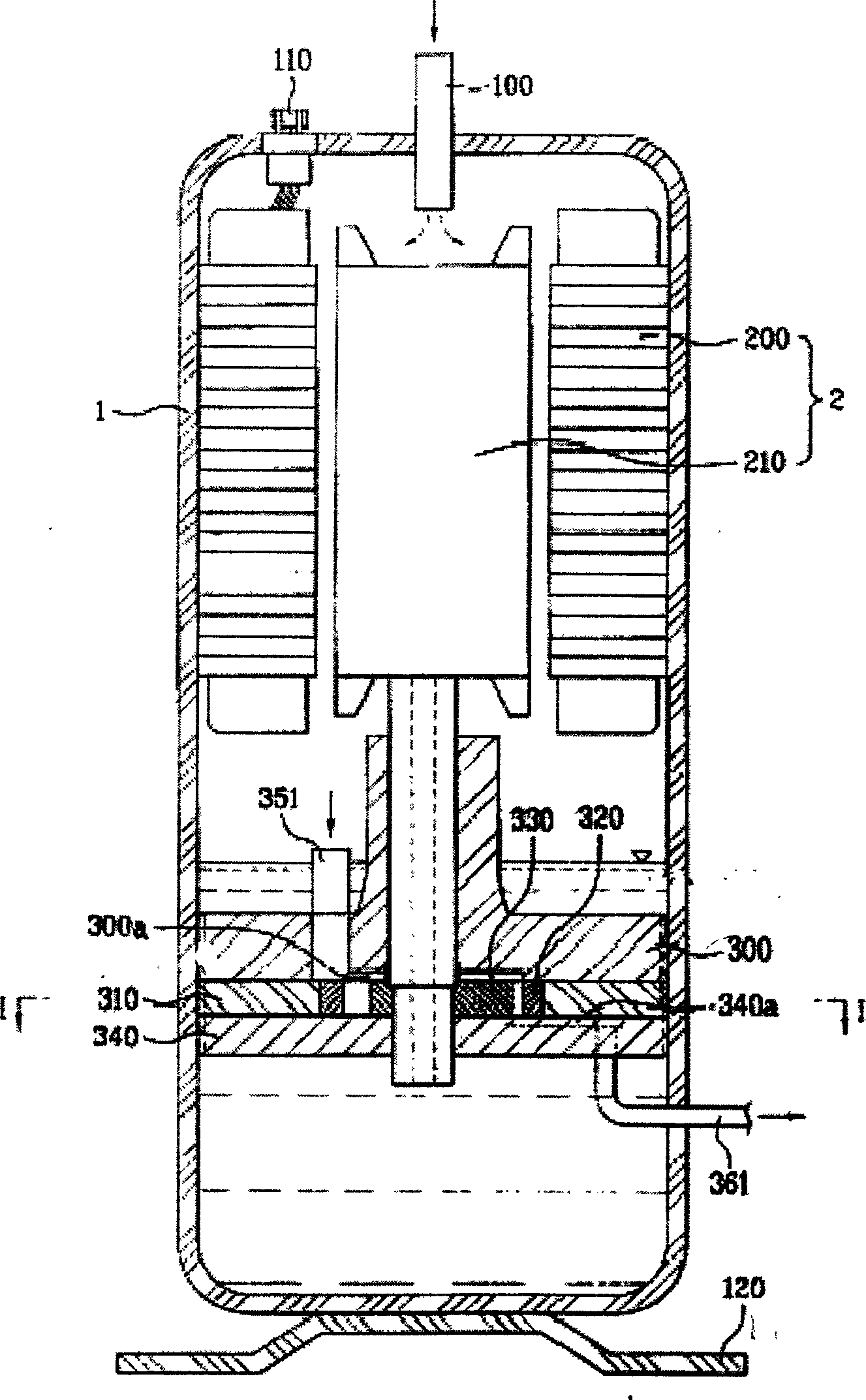

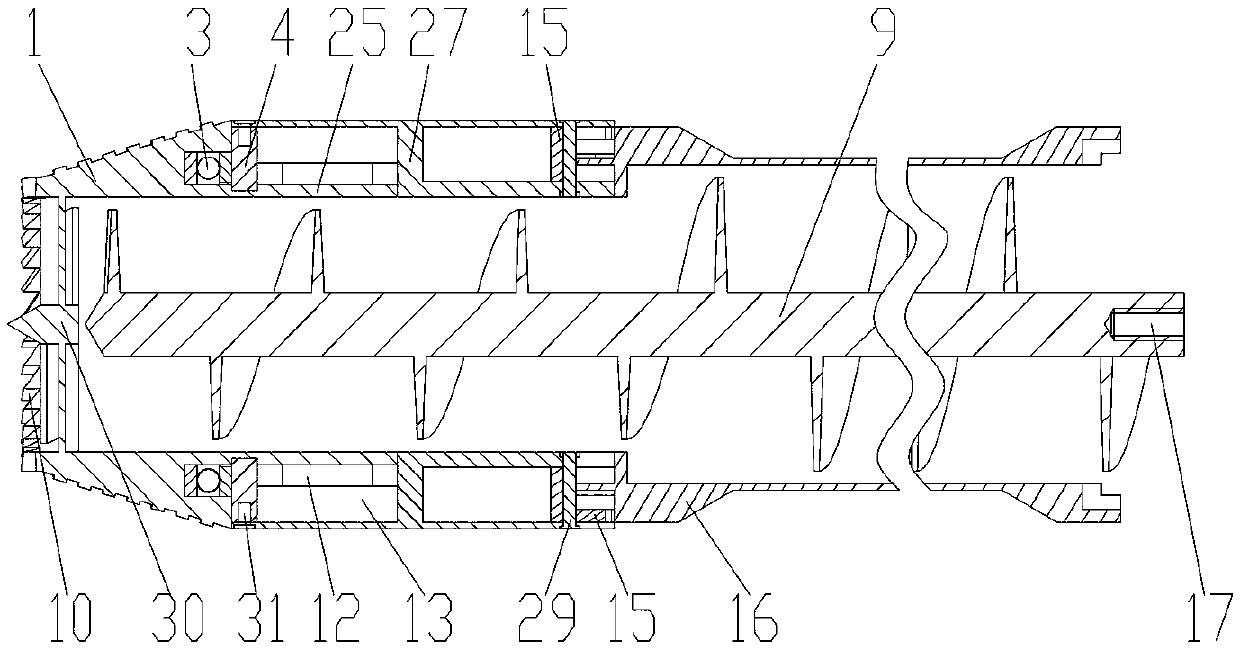

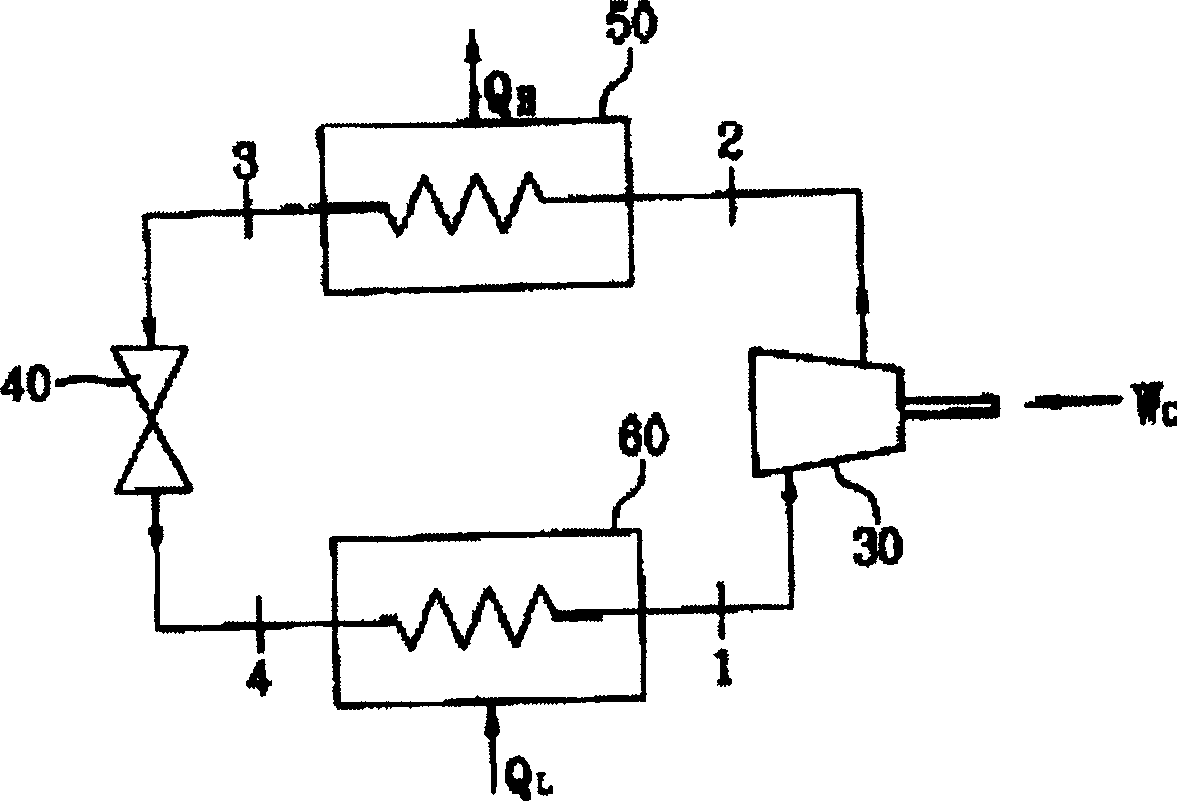

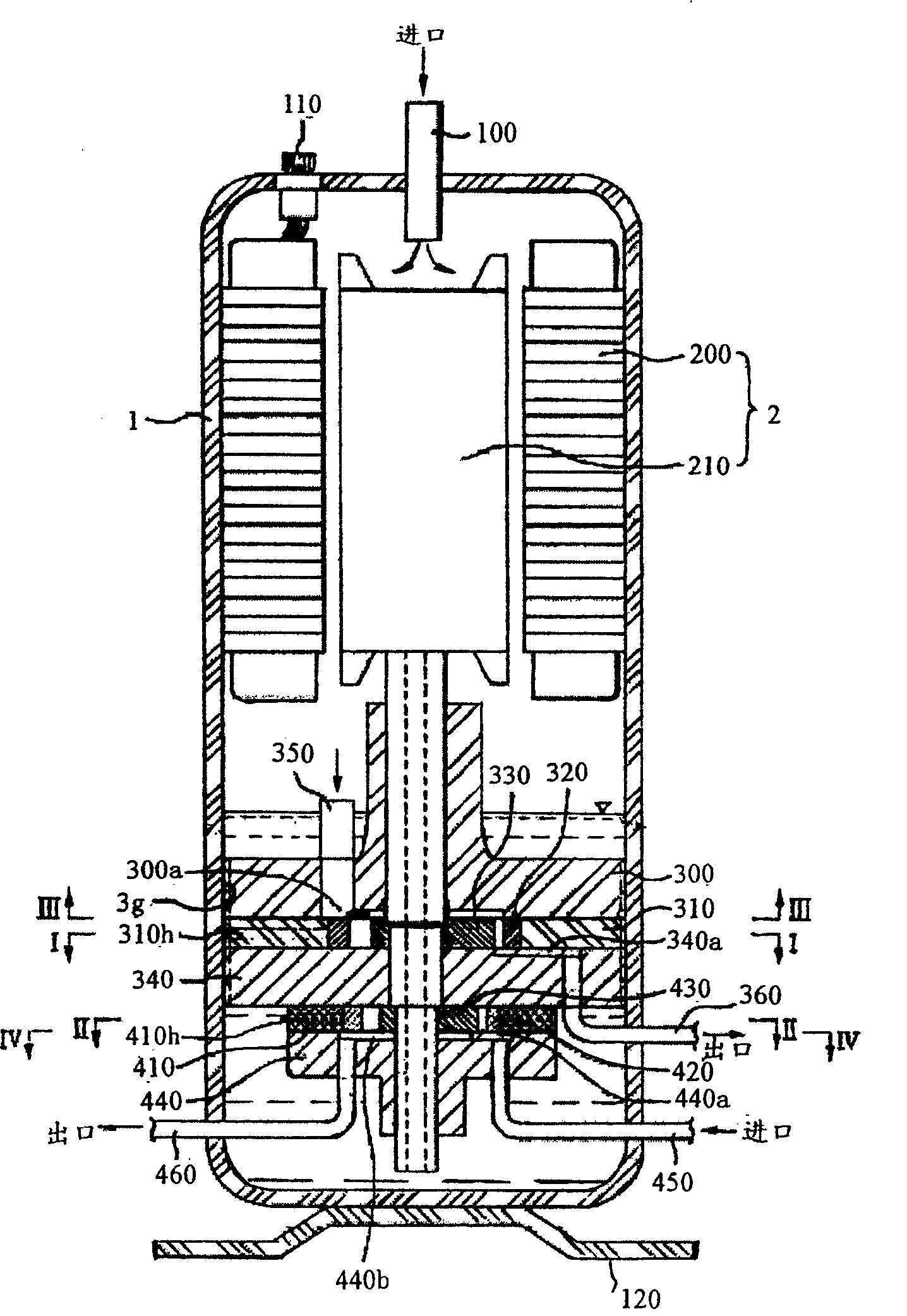

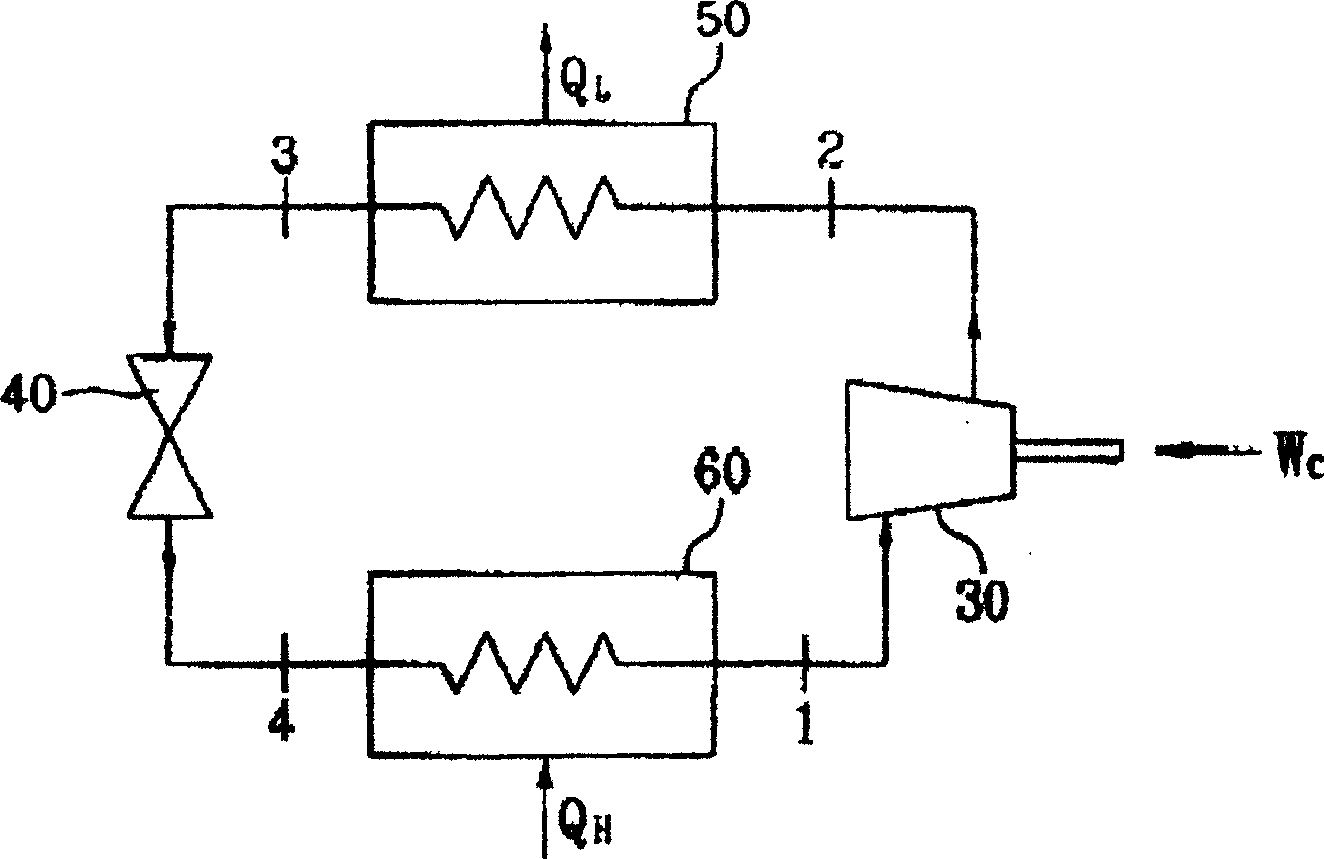

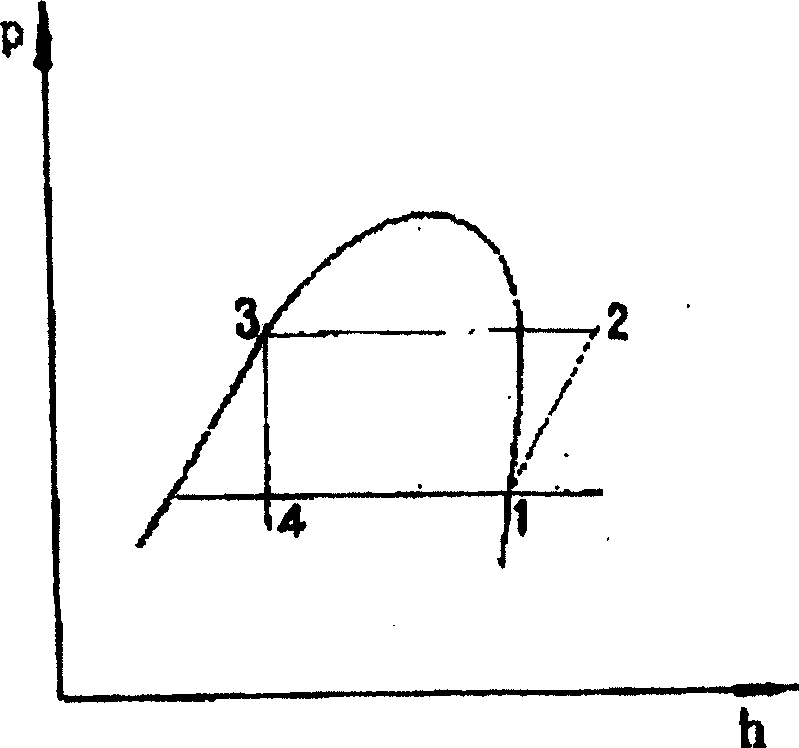

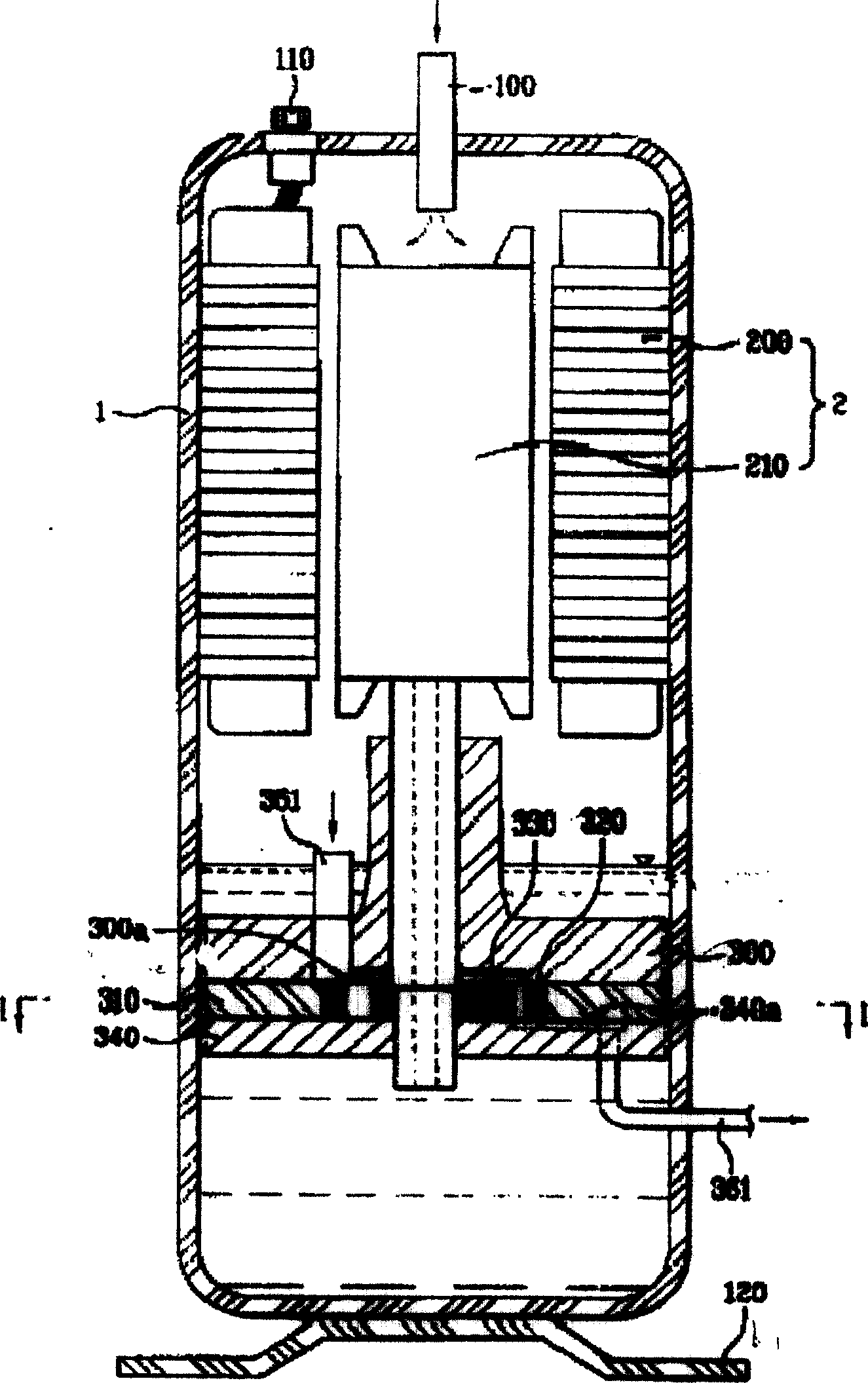

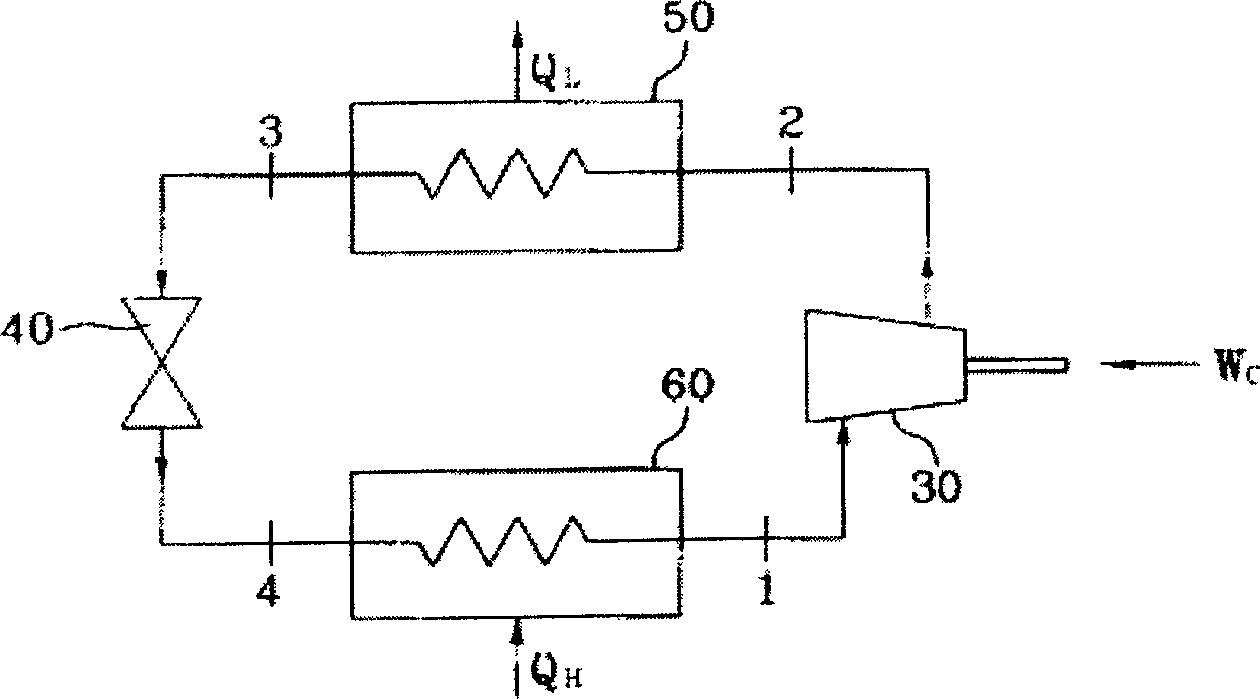

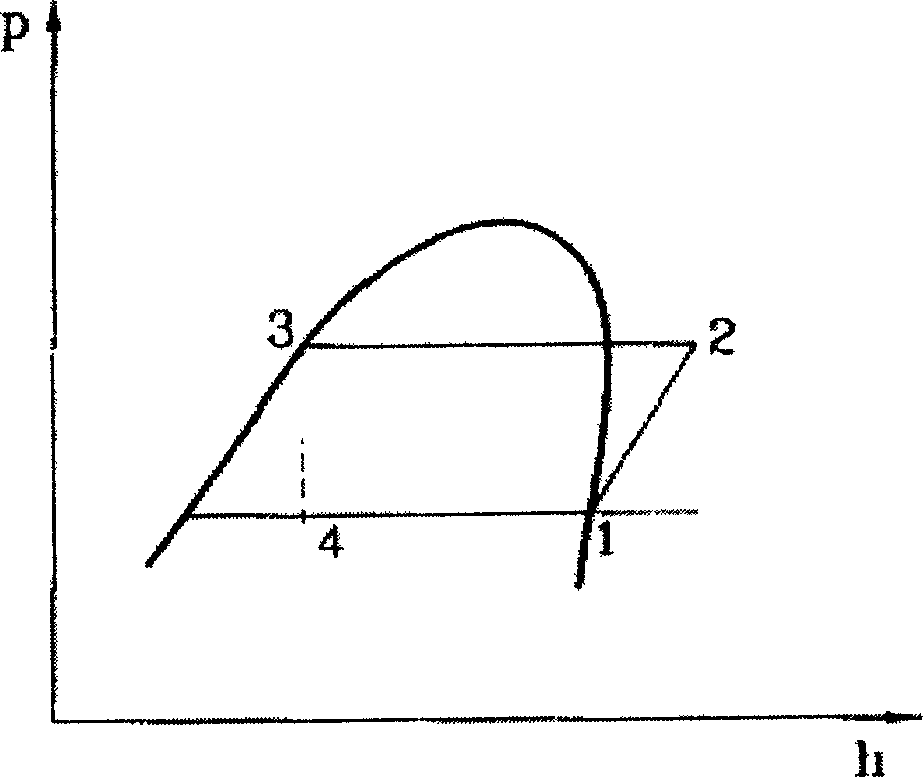

Gear type compressor

InactiveCN1704596AReduce vibrationReduce noiseRotary piston pumpsRotary piston liquid enginesChillerCoefficient of performance

This invention relates to a gear-type contractor, which comprises the driving part, the compressing part used for compressing coolant by the dynamic from the driving part, the gear-type swelling part used for swell the reflow coolant after flowing from compressing part and chiller; wherein the outline dimensions of the swelling part and compressing part are same. Said contractor can increase the coefficient of performance of refrigerating system, and can uses carbon dioxide to replace traditional coolant, which is benefit for environmental protection; besides, the force and force moment of the inner gear and outer gear are balance, so it can decrease the shake and noise when operating. The same size of compressing part and swelling part makes them can be assembled integrated, and the swelling plate and compressing plate can be used as one element.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

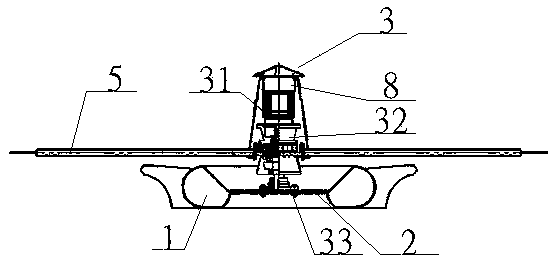

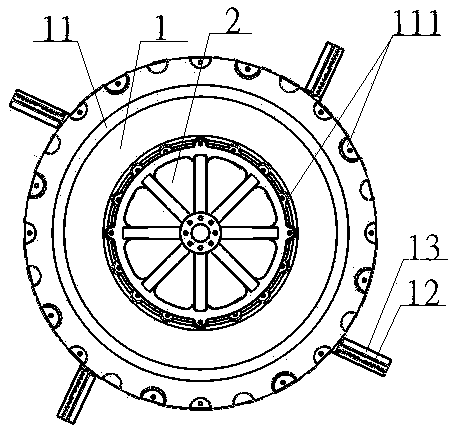

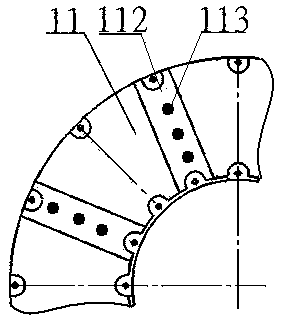

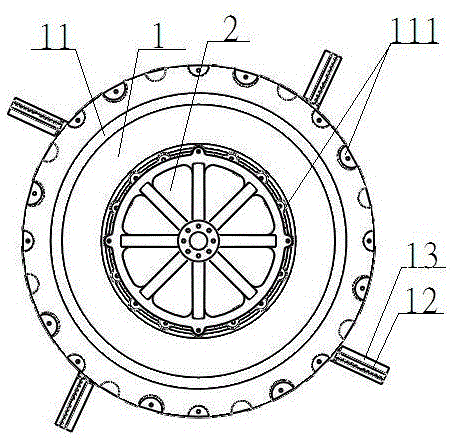

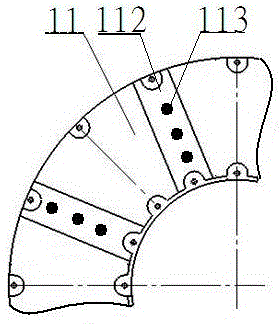

Self-floating type impeller aerator

The invention discloses a self-floating type impeller aerator, which comprises a buoy impeller (1), wherein the buoy impeller (1) is provided with a power device (3) through a connecting support plate (2), and comprises a sealing buoy (11) and blades (12), the power device (3) consists of a vertical motor (31), a speed reduction mechanism (32) and a rotary flange (33), the integral blade (12) is in an L shape, and is uniformly provided with a plurality of water division holes (6) and a water division groove (7), and the blades (12) are fixedly and adjustably connected with the sealing buoy (11) by virtue of the blade bottom plate (13). The aerator not only solves the problems of large size of aeration equipment and inconvenient production, transportation, assembly and use as the traditional impeller aerator uses the bearing devices, such as floating balls, to bear the power device of the aerator, but also effectively solves the problems of single type of traditional blade and unable aeration, water tillage and surging.

Owner:江苏现代渔业装备科技有限公司

Air core pump with impeller center boost adjustment

ActiveCN103206383BAvoid or suppress cavitationAvoid or suppress harmSpecific fluid pumpsPump componentsImpellerCavitation

The invention provides a vapor-core pump with an impeller central pressure supplement regulator. The impeller central pressure supplement regulator enables the vapor-core pump to operate under higher performance and efficiency. By the aid of the impeller central pressure supplement regulator for controlling front and back pressures at a valve port of an inlet throttle valve, cavitation caused by excessively low central impeller pressure can be avoided or inhibited effectively, and the damage caused by cavitation can also be avoided.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Gear type compressor

InactiveCN1704599AImprove the coefficient of performanceForce and moment balanceRotary piston pumpsRotary piston liquid enginesChillerCarbon dioxide

This invention relates to a gear-type contractor, which comprises motor, gear-type compressing part used for compressing coolant flow from evaporator by the driving of motor, and gear-type swelling part used for swelling the reflow coolant after flowing contractor and chiller; wherein the gear-type compressing part comprises main bearing, compressed cylinder, outer gear, inner gear and compressed plate; the gear-type swelling part comprises swelling plate, swelling cylinder, outer gear, inner gear, and supplementary bearing; the inner gears of compressing part and swelling part are mosaic connected with the rotation shaft of the motor. Said invention can increase the coefficient of performance of refrigerating system, and can use carbon dioxide to replace traditional coolant, which is benefit for environmental protection.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

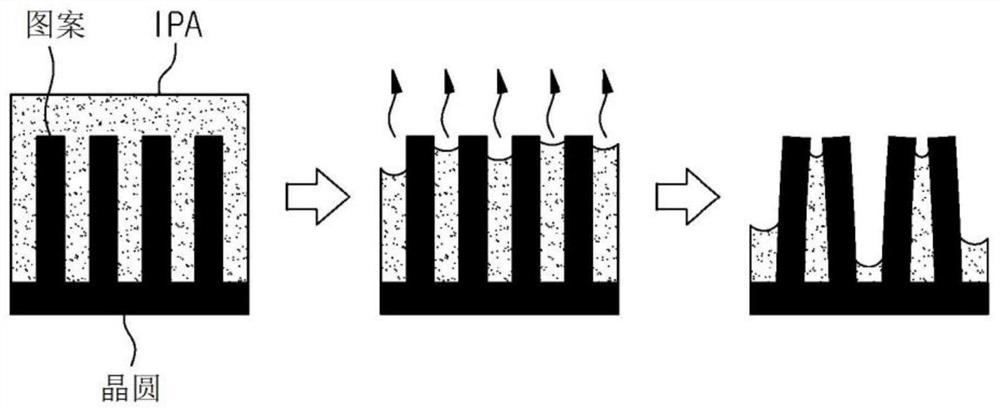

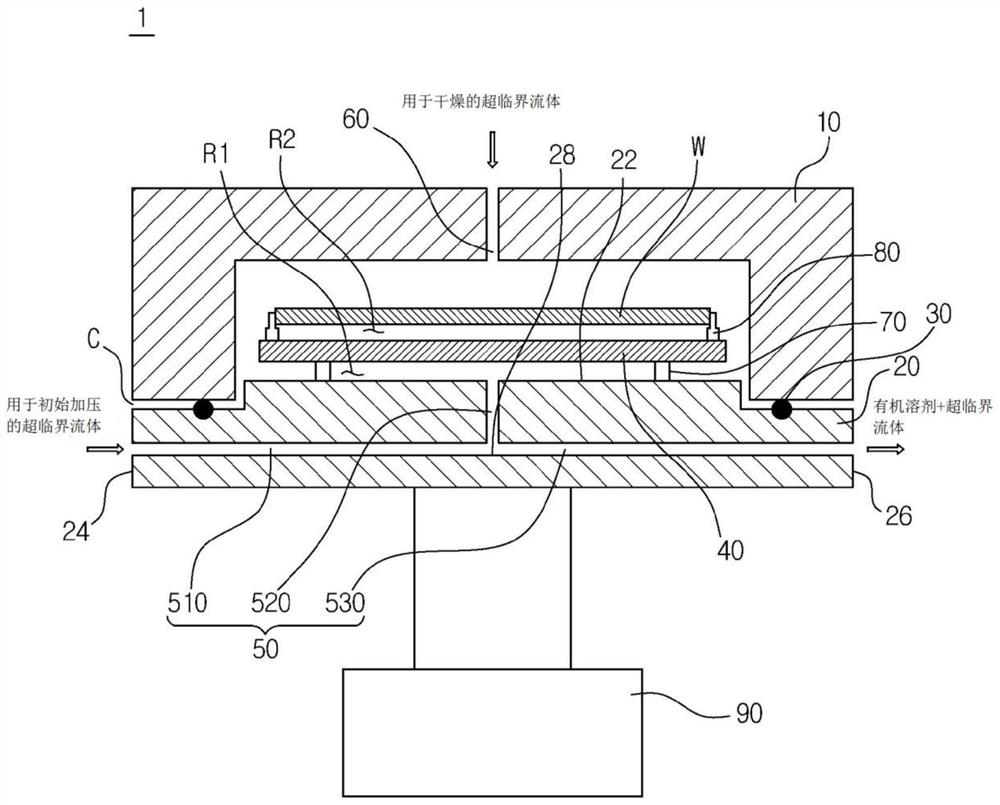

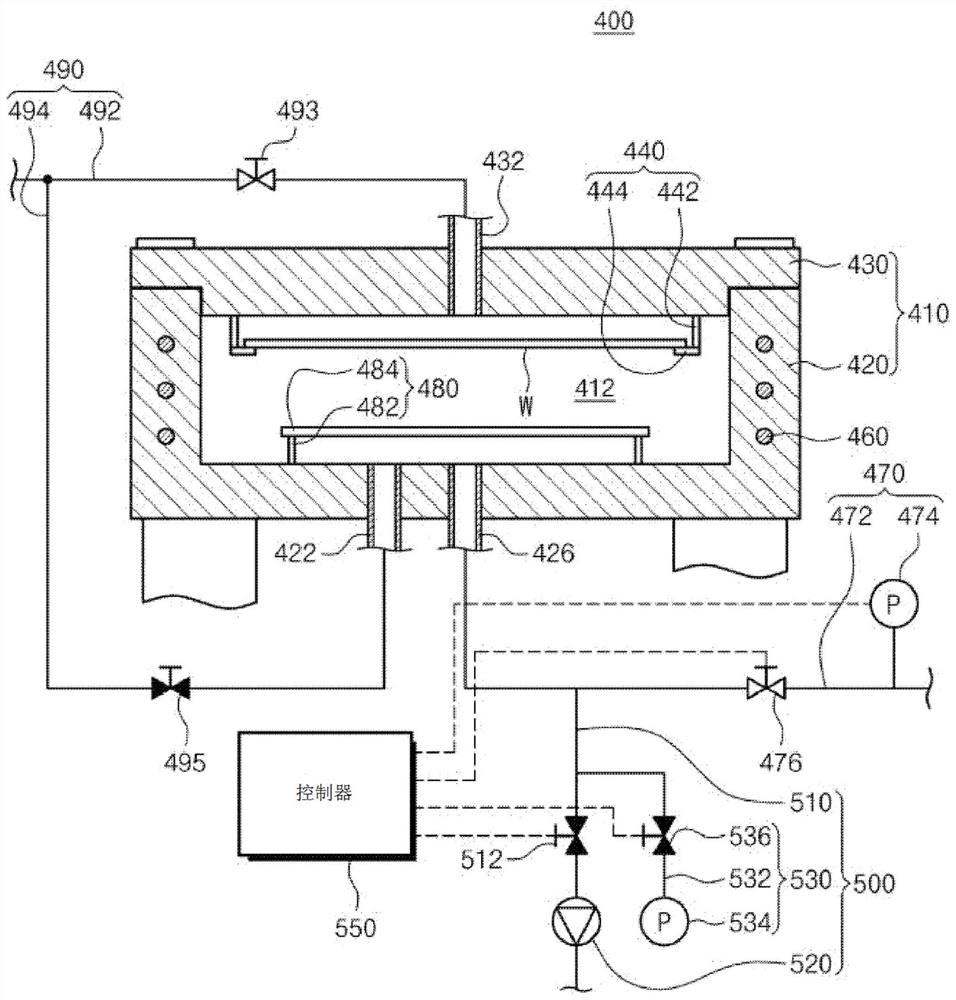

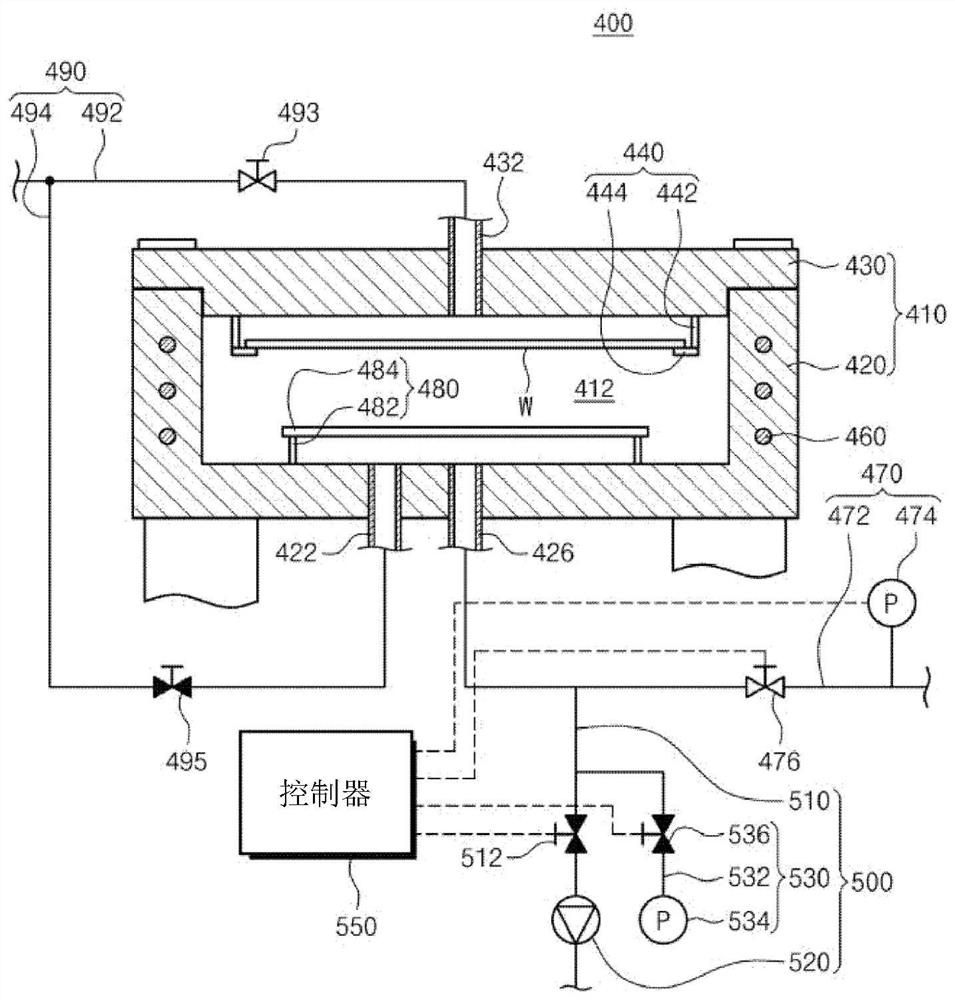

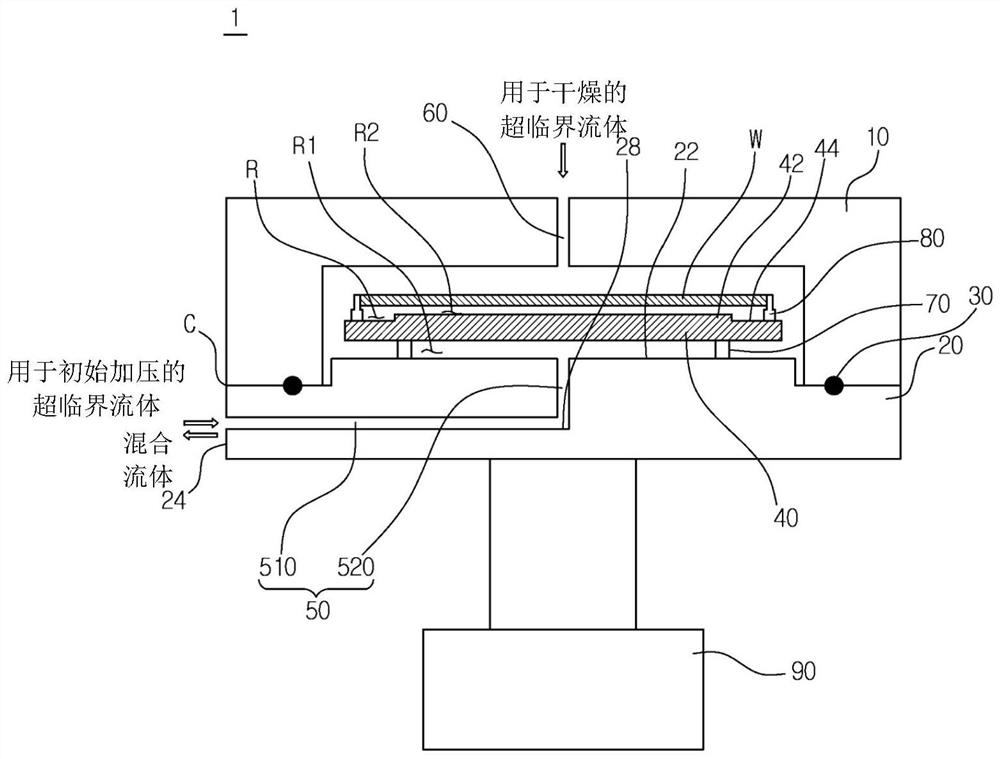

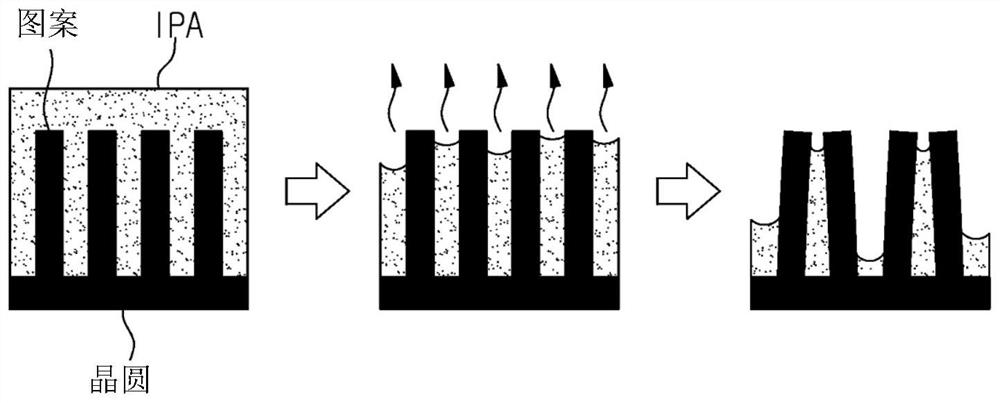

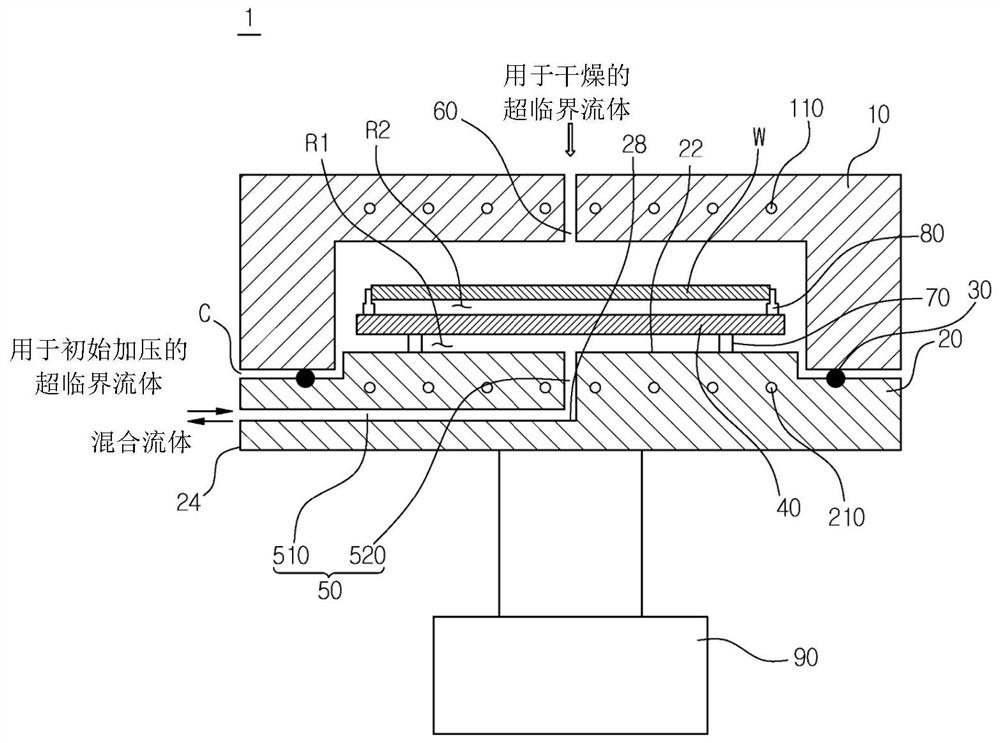

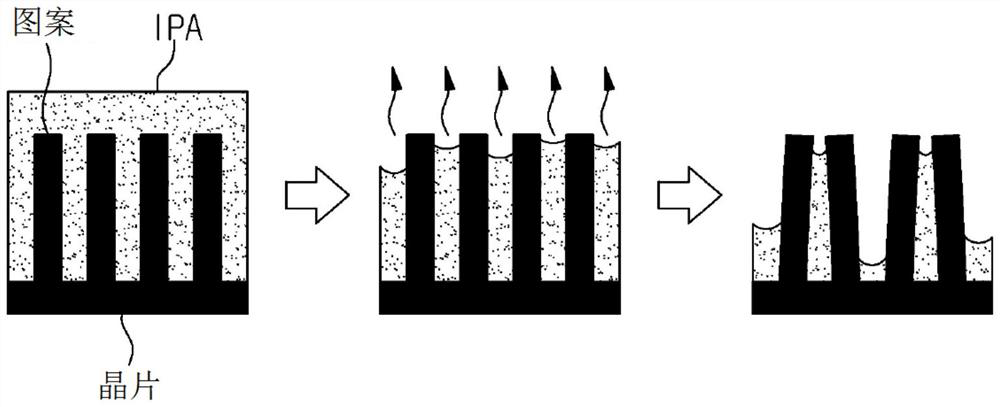

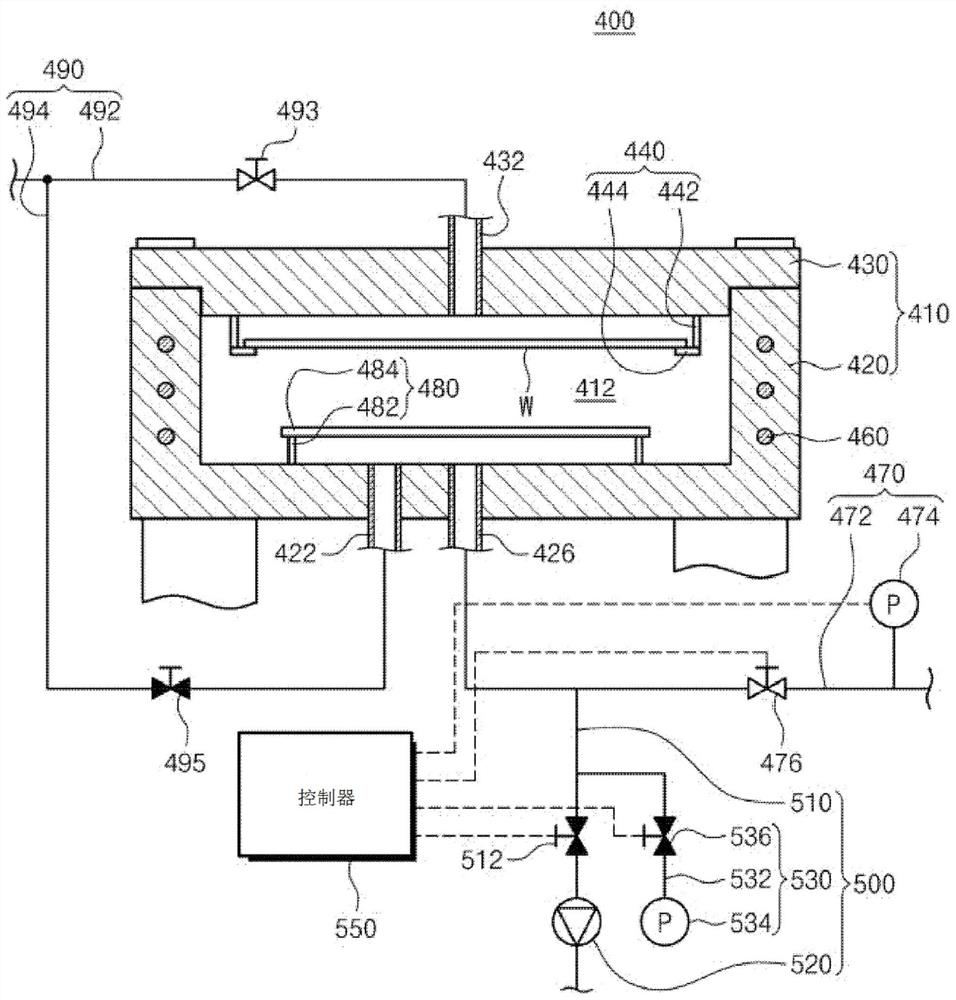

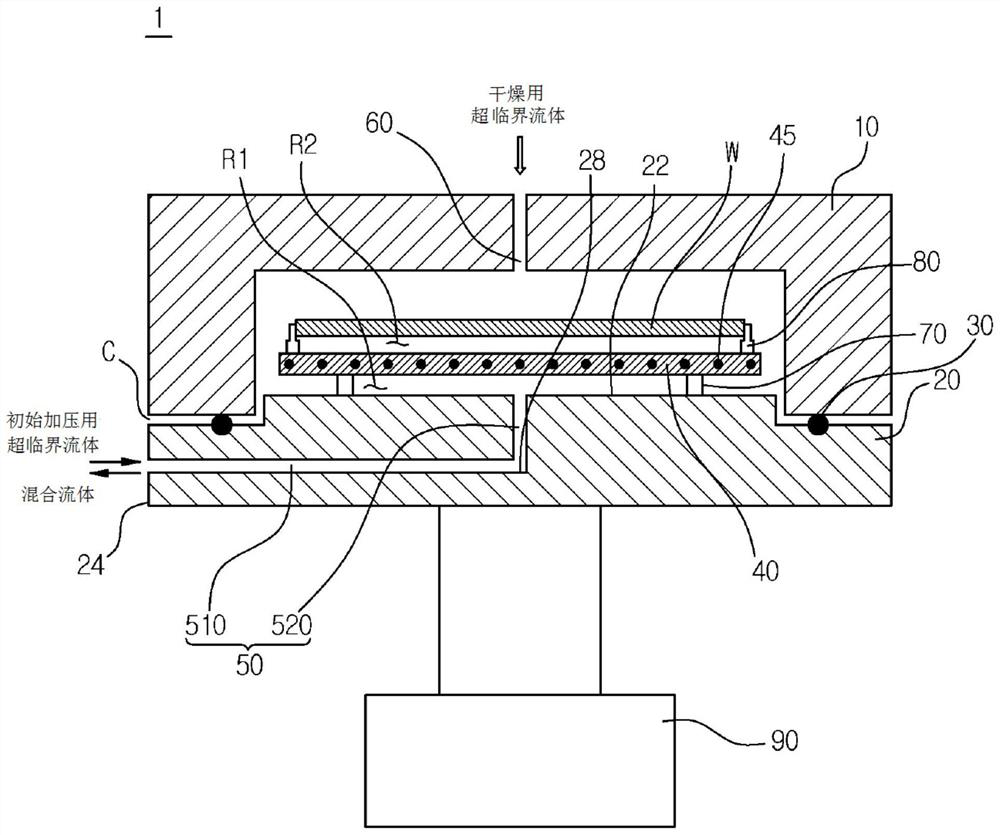

Substrate drying chamber

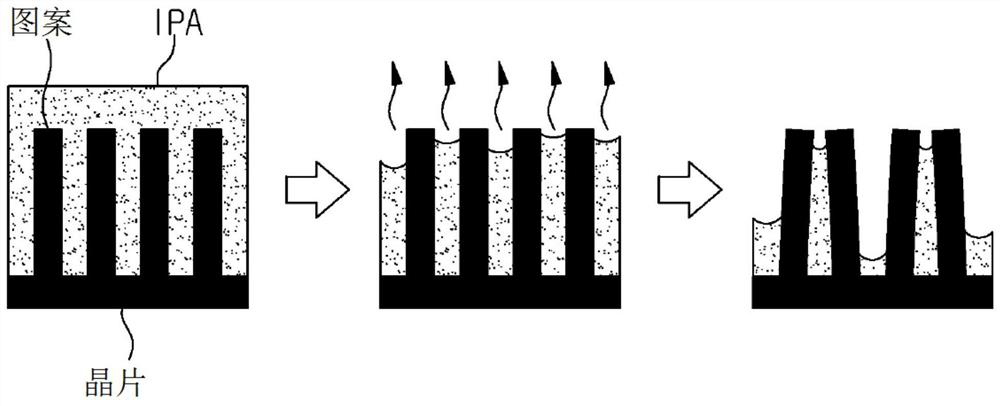

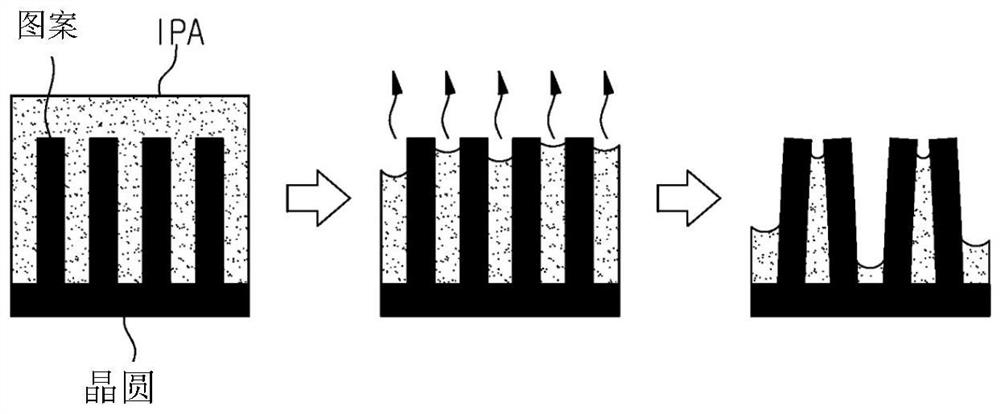

PendingCN113272946AImprove drying efficiencyReduce depositionSemiconductor/solid-state device manufacturingOrganic solventMechanical engineering

The present invention relates to a substrate drying chamber. The present invention includes: an upper housing; a lower housing which is coupled to the upper housing to be opened or closed; a sealing portion which is provided between coupling surfaces of the lower housing and the upper housing; a substrate mounting plate which is coupled to the bottom surface of the lower housing and on which a substrate having organic solvent formed thereon is mounted; an integrated supply / discharge port which extends from one side surface to the other side surface in the lower housing, and extends from a middle region between the one side surface and the other side surface towards the substrate mounting plate so as to provide a supply path for supercritical fluid for initial compression and a discharge path for supercritical fluid in which the organic solvent formed on the dried substrate is dissolved; and an upper supply port which is formed at the central region of the upper housing to face the substrate mounting plate so as to provide a supply path for supercritical fluid for drying.

Owner:MUJIN ELECTRONICS CO LTD

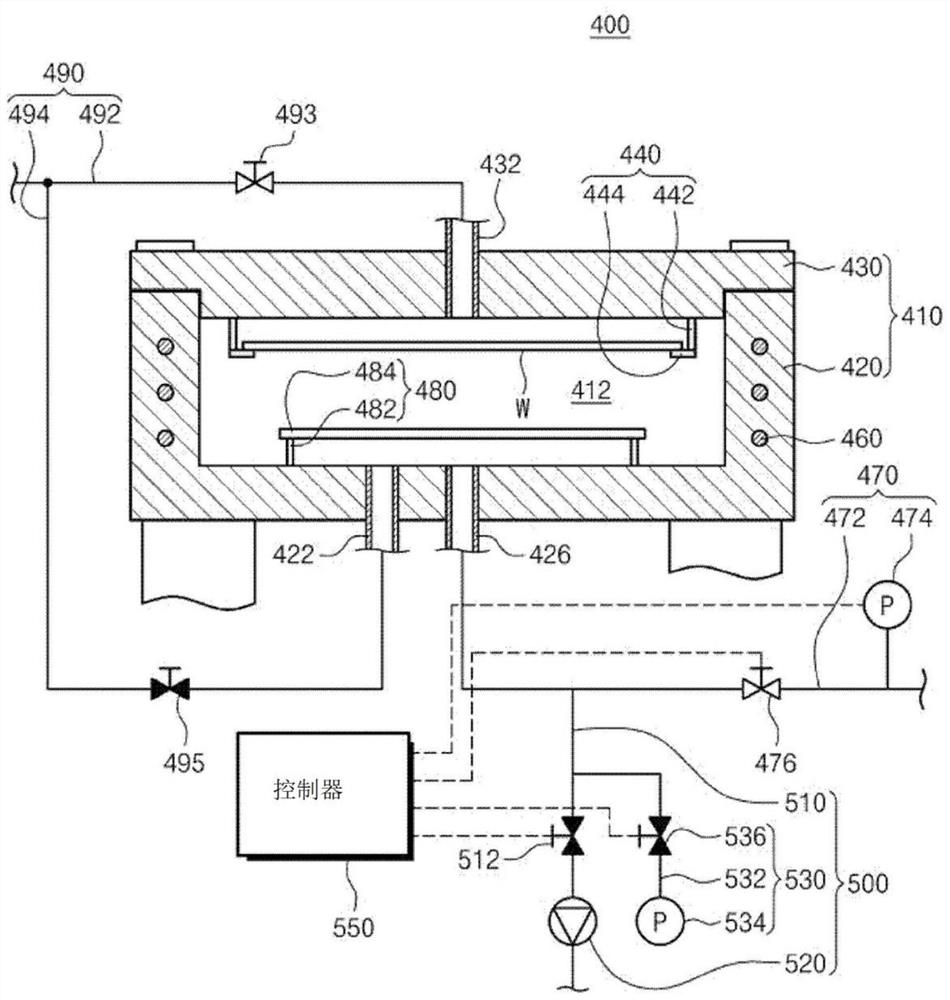

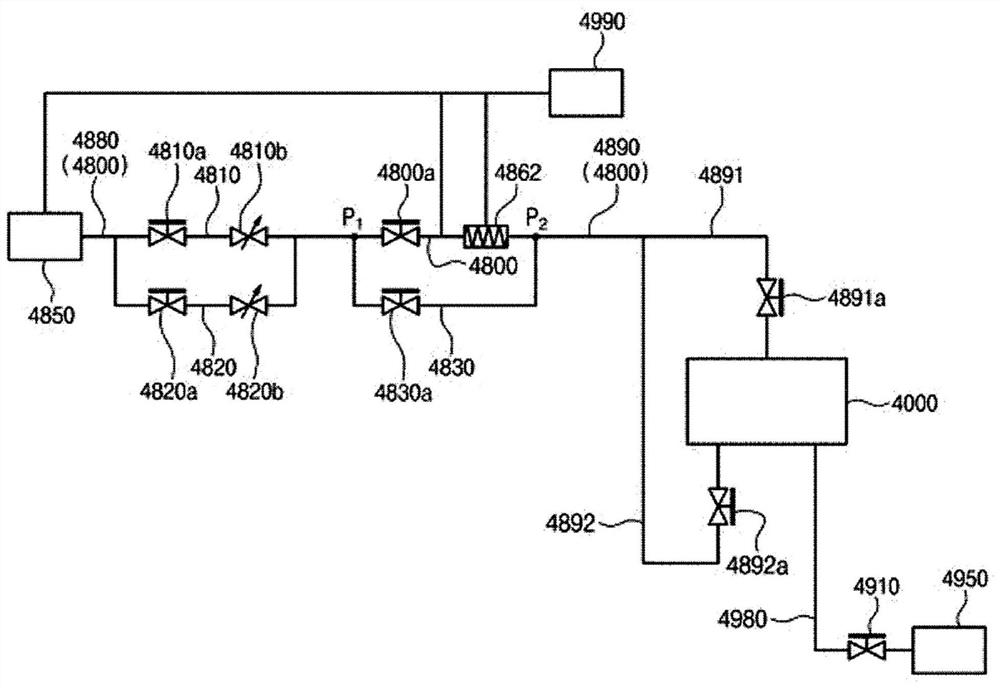

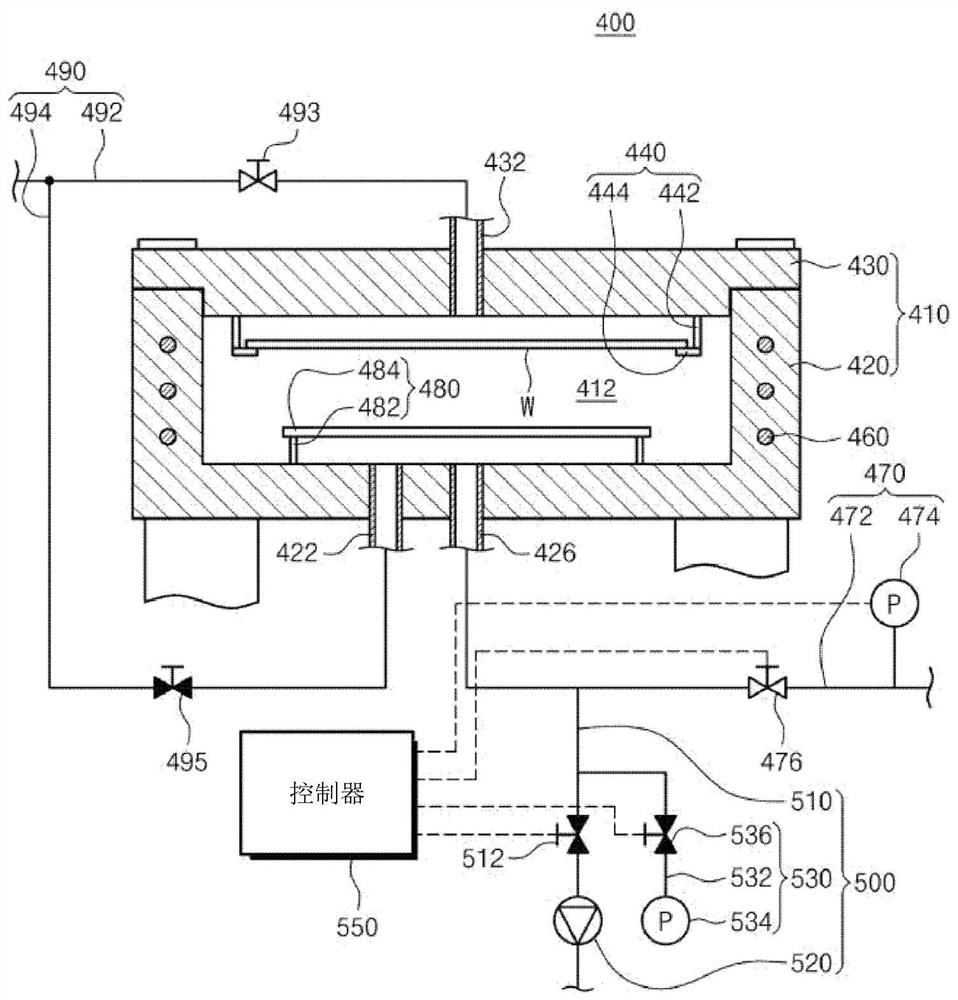

Substrate drying device

PendingCN112242323AImprove drying efficiencyAvoid damageSemiconductor/solid-state device manufacturingEngineeringSupercritical fluid

The present invention relates to a substrate drying apparatus, comprising: a chamber; a supercritical fluid generation and storage unit that generates and stores a supercritical fluid to be supplied into the chamber; and a supercritical fluid supply adjustment unit that adjusts the supercritical fluid to be supplied to the chamber stored in the supercritical fluid generation and storage unit, wherein the chamber includes: an upper housing; a lower housing; a substrate placing plate on which the substrate on which the organic solvent is formed is arranged; an upper supply port formed to face the substrate placement plate in a central region of the lower case and providing a supply path of a supercritical fluid for drying; and an integrated supply and discharge port extending from a side surface of the lower case to the center region and formed to face the substrate placement plate in the center region of the lower case, and a supply path for the supercritical fluid for initial pressurization and a discharge path for a mixed fluid in which an organic solvent is dissolved in the supercritical fluid for drying after drying is performed using the supercritical fluid for drying.

Owner:MUJIN ELECTRONICS CO LTD

Substrate drying chamber

InactiveCN113983773AImprove throughputReduce processing timeDrying solid materials without heatDrying gas arrangementsOrganic solventEngineering

The invention provides a substrate drying chamber. The substrate drying chamber comprises an upper case; a lower case coupled to the upper case to be opened or closed; a substrate placement plate coupled to the lower case and having an upper surface facing the upper case, wherein a central protruding region and an outer region are formed on the upper surface of the upper case; a substrate support that supports the substrate and separates the substrate from the upper surface of the substrate placement plate; an upper supply port for providing a supply path for the drying supercritical fluid; and an integrated supply and discharge port for providing a supply path for an initially pressurized supercritical fluid and a discharge path for a mixed fluid, where an organic solvent is dissolved in the drying supercritical fluid after a drying process performed with the drying supercritical fluid supplied through the upper supply port. According to the invention, the processing time of the fluid drying process is shortened.

Owner:MUJIN ELECTRONICS CO LTD

Gear type compressor

InactiveCN100487248CImprove the coefficient of performanceImprove protectionRotary piston pumpsRotary piston liquid enginesCoolant flowEngineering

This invention relates to a gear-type contractor, which comprises motor, gear-type compressing part used for compressing coolant flow from evaporator by the driving of motor, and gear-type swelling part used for swelling the reflow coolant after flowing contractor and chiller; wherein the gear-type compressing part comprises main bearing, compressed cylinder, outer gear, inner gear and compressed plate; the gear-type swelling part comprises swelling plate, swelling cylinder, outer gear, inner gear, and supplementary bearing; the inner gears of compressing part and swelling part are mosaic connected with the rotation shaft of the motor. Said invention can increase the coefficient of performance of refrigerating system, and can use carbon dioxide to replace traditional coolant, which is benefit for environmental protection.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

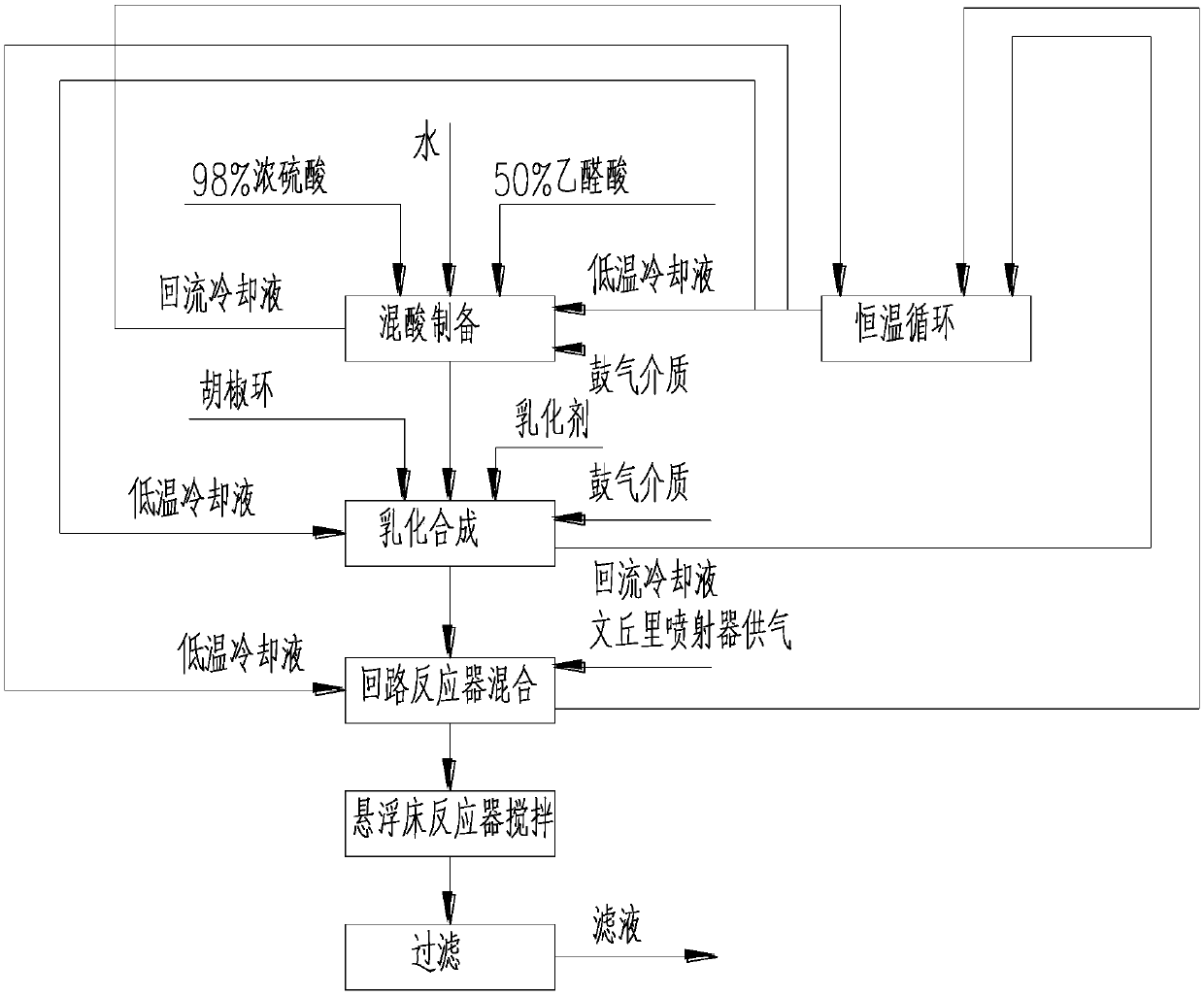

Method and device for synthesizing 3,4-dioxymethylene mandelic acid by enhanced emulsification

ActiveCN110862370AIncrease surface areaIncrease contact areaOrganic chemistryFlow mixersGlyoxylic acidEmulsion

The invention discloses a method for synthesizing 3,4-dioxymethylene mandelic acid by enhanced emulsification. According to the method, gas is introduced into a reaction system in mixed acid preparation and emulsification synthesis processes, so that a large quantity of bubbles are produced in the reaction system, the surface area of reactants is enlarged, the contact area between the reactants isincreased, and the reaction conversion rate and yield can be increased. By use of the homogenization effect of the emulsification process, 1,3-benzodioxole is uniformly dispersed in glyoxylic acid with tiny droplets, the contact efficiency of the reactants can be improved, and the product purity and yield can be increased. A product is used as an emulsifier, a stable emulsion system can be formedwhile no substances outside the reaction system are introduced, and the product separation process is simpler and easier. An emulsified solution is dispersed into tiny droplets by a loop reactor witha Venturi ejector and a circulating suspended bed reactor in the reaction process to form a microreaction system, the heat and mass transfer efficiency is improved, and the problem of production of byproducts due to non-uniform heat transfer is inhibited.

Owner:山东天大泰泽环保科技有限公司

Substrate drying chamber

PendingCN113764306APrevent collapseImprove supercritical drying efficiencyDrying solid materials without heatDrying gas arrangementsSupercritical dryingOrganic solvent

The invention provides a substrate drying chamber. The substrate drying chamber comprises an upper shell; a lower shell; a heater embedded in at least one of the upper shell and the lower shell; a substrate placement plate on which the substrate on which the organic solvent remains is placed; an upper supply port formed in a central region of the upper case to face the substrate placement plate, and providing a supply path of the supercritical fluid for drying; and an integrated supply and discharge port formed to extend from a side surface of the lower case to a central region of the lower case and face the substrate placement plate in the central region of the lower case, and providing a supply path for an initially pressurized supercritical fluid and a discharge path for a mixed fluid, in the mixed fluid, after the supercritical fluid for drying supplied through the upper supply port is dried, the organic solvent is dissolved in the supercritical fluid for drying. According to the present invention, the pattern formed on the substrate can be prevented from collapsing and the supercritical drying efficiency can be improved.

Owner:MUJIN ELECTRONICS CO LTD

Gear type compressor

InactiveCN1704598AImprove the coefficient of performanceForce and moment balanceRotary piston pumpsRotary piston liquid enginesChillerMain bearing

This invention relates to a gear-type contractor. The compressing part comprises main bearing, compressed cylinder, outer gear, inner gear and compressing plate; wherein the main bearing is fixed below the driving part, and the ring form compressed cylinder is set below the base bearing and connected together; the outer gear is set inside the cylinder with rotary form, and the inner gear is set inside the outer gear, which will receive dynamic from motor and engage with outer gear to rotary, compressing coolant; the compressing plate is set below the compressed cylinder and connected with it; the auxiliary induction pipe which will send the coolant to inner space of the outer gear, and the output pipe which will send the compressed coolant to chiller can be set in two of the base bearing, the compressed cylinder or the compressing plate. Said invention can increase the coefficient of performance of refrigerating system, and can use carbon dioxide to replace traditional coolant, which is benefit for environmental protection.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Substrate drying chamber

PendingCN112117212AImprove drying efficiencySmall working volumeSemiconductor/solid-state device manufacturingPhysicsChemistry

A substrate drying chamber includes: a substrate placement plate; an upper supply port that provides a supply path for the supercritical fluid for drying; an integrated supply and discharge port thatprovides a supply path for the supercritical fluid for initial pressurization and a discharge path for a mixed fluid in which an organic solvent is dissolved in the supercritical fluid for drying after drying is performed; and a heating member that heats the supercritical fluid for initial pressurization and the mixed fluid. According to the present invention, it is possible to solve the problem of causing particulate contamination on a substrate by liquefying or vaporizing a supercritical fluid due to a cooling phenomenon caused by a decrease in pressure in a process of introducing the supercritical fluid for initial pressurization into a chamber; the problem addressed by the present invention is that of causing microparticle contamination on a substrate or collapsing a pattern formed onthe substrate due to the surface tension of a mixed fluid by phase separation of the mixed fluid due to a cooling effect when the mixed fluid is discharged after the completion of a drying step.

Owner:MUJIN ELECTRONICS CO LTD

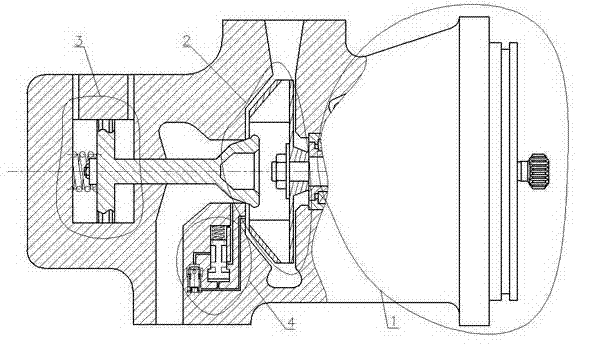

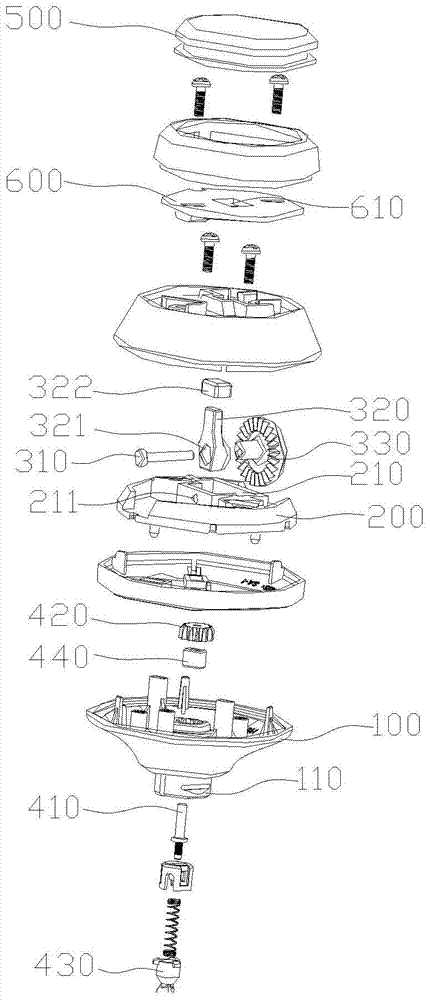

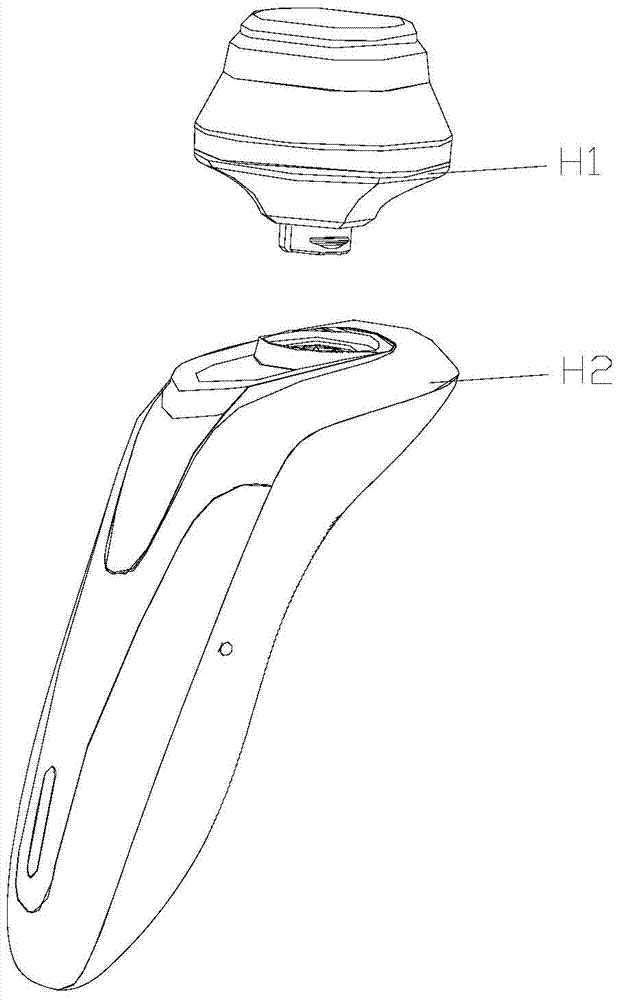

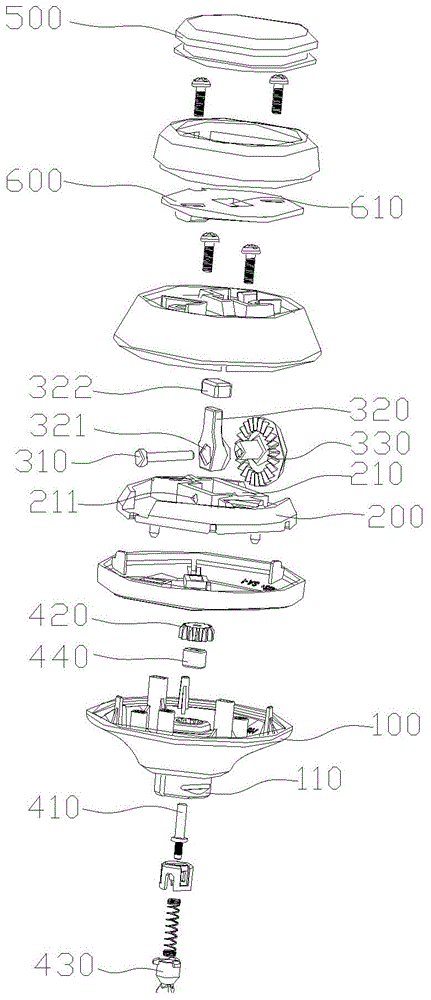

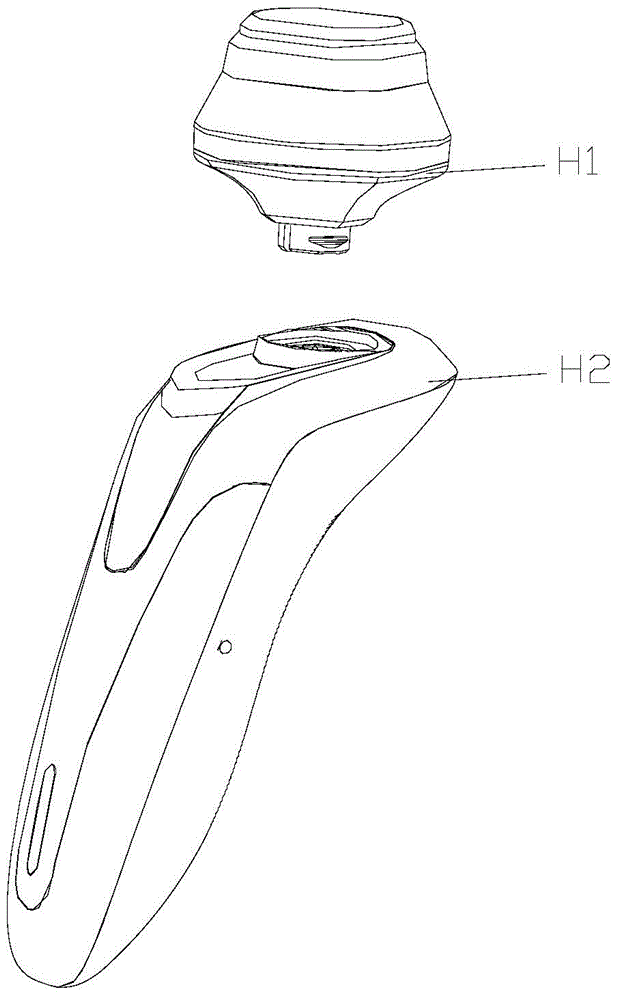

Vibration mechanism and its components

ActiveCN104826787BCompact structureSmall working volumeMechanical vibrations separationMechanical engineeringGenerating unit

A vibration mechanism and its components include a vibration generating part, a vibration driving part and a vibration acting part. The vibration generating part includes a knocking part, a rotating shaft and an eccentric part. One end of the striking part is limited in the bracket groove, and one end of the rotating shaft is connected with the eccentric part. The vibration driving part is used to drive the eccentric, and the vibration acting part is covered on the vibration generating part. The vibrating mechanism of the present invention can be directly installed on the handle assembly of the existing shaver to realize local massage, and after disassembly, the handle assembly can also be used for shaving, realizing "one machine with multiple functions".

Owner:SHANGHAI POVOS ELECTRIC WORKS

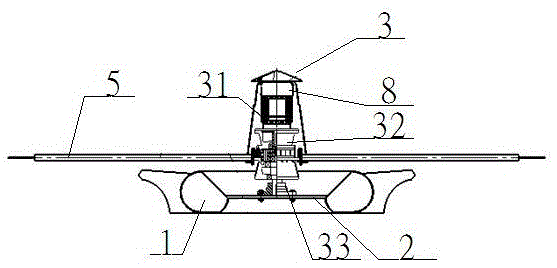

A small all-electric trenchless horizontal directional drilling rig

InactiveCN103867125BSimple structureReduce manufacturing costDirectional drillingUnderground pipelineDirectional drilling

A small-sized full electric non-excavation horizontal oriented drill rig belongs to a non-excavation construction machinery for paving, replacing and repairing various underground pipelines. The technical key points are that the small-sized full electric non-excavation horizontal oriented drill rig comprises a cutting drill bit (1), a drill bit rotary cutting driving device, a buffer device, a soil rear postposition spiral conveying device and a drill rod propelling pulling-back device; the cutting drill bit (1) is of a hollow drill bit; the drill bit rotary cutting driving device is arranged behind a cutting drill bit conical drum (2); the buffer device is connected behind the drill bit rotary cutting driving device; the soil postposition spiral conveying device is arranged on the axis of the cutting drill bit (1); the rear end of the last section of the soil postposition spiral conveying device is connected with the drill bit propelling pulling-back device connected with a power supply. The output of the postposition spiral soil cutting adopts full electric driving, the structure can be simplified, and the production cost is reduced; a work pit is firstly excavated during work, and the holing and pulling-back are performed at one step in the horizontal direction; the guiding and hole expanding processes are omitted, the construction progress can be accelerated, the construction efficiency can be improved, and the small-sized full electric non-excavation horizontal oriented drill rig is widely used for paving and updating urban and rural underground pipelines.

Owner:XIANGTAN UNIV

A gear type compressor

InactiveCN100465446CImprove the coefficient of performanceEasy to useRotary piston pumpsRotary piston liquid enginesEngineeringCoefficient of performance

A gear compressor comprises a shell and an inner motor installed inside the shell, a gear compressing section drove by the motor to compress the cold media from the evaporator, a gear inflation section to expand the cold media flowing from the condenser. The ratio of the outlet area of the compressing board in the compressing section to the inlet area of the main shaft is 1:1.3 ~ 1:3. The ratio of the inlet area to the outlet area of the sub shaft in the inflation section is 1:1.3 ~ 1:3.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

A gear type compressor

InactiveCN100465445CImprove the coefficient of performanceImprove protectionRotary piston pumpsRotary piston liquid enginesEngineeringCylinder block

This invention relates to a gear-type contractor. The compressing part comprises main bearing, compressed cylinder, outer gear, inner gear and compressing plate; wherein the main bearing is fixed below the driving part, and the ring form compressed cylinder is set below the base bearing and connected together; the outer gear is set inside the cylinder with rotary form, and the inner gear is set inside the outer gear, which will receive dynamic from motor and engage with outer gear to rotary, compressing coolant; the compressing plate is set below the compressed cylinder and connected with it; the auxiliary induction pipe which will send the coolant to inner space of the outer gear, and the output pipe which will send the compressed coolant to chiller can be set in two of the base bearing, the compressed cylinder or the compressing plate. Said invention can increase the coefficient of performance of refrigerating system, and can use carbon dioxide to replace traditional coolant, which is benefit for environmental protection.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Separable vibrating mechanism and assembly thereof

ActiveCN104826787ACompact structureSmall working volumeMechanical vibrations separationMultiple functionMassage

The invention discloses a vibrating mechanism. The vibrating mechanism comprises a vibrating generation part, a vibrating driving part and a vibrating action part, wherein the vibrating generation part comprises a knocking piece, a rotary shaft and an eccentric piece; the rotary shaft is in clearance fit with a through hole formed in a support tank body; one end of the knocking piece is defined in the support tank body; one end of the rotary shaft is connected with the eccentric piece. The vibrating driving part is used for driving the eccentric piece, and the vibrating action part covers the vibrating generation part. The vibrating mechanism is directly mounted on a conventional shaver handle assembly to achieve local massage, and the handle assembly can be used for shaving after the vibrating mechanism is disassembled, so that multiple functions are realized for one machine.

Owner:SHANGHAI POVOS ELECTRIC WORKS

Gear type compressor

InactiveCN1704595AReduce vibrationReduce noiseRotary piston pumpsRotary piston liquid enginesCoolant flowEngineering

This invention relates to a gear-type contractor, which comprises the driving part, and the compressing part set above the driving part, characterized in that it uses the dynamic from the driving part to compress the coolant flow from the evaporator; and above the compressing part there is a gear-type swelling part, which will swell the reflow coolant after it flow from compressing part and chiller. Said contractor can increase the coefficient of performance of refrigerating system, and can use carbon dioxide to replace traditional coolant, which is benefit for environmental protection; besides, the force and force moment of the inner gear and outer gear of said contractor are balance, so it can decrease the shake and noise when operating.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

A self-floating impeller aerator

ActiveCN104221990BIncrease in sizeSmall working volumePisciculture and aquariaImpellerElectric machinery

The invention discloses a self-floating type impeller aerator, which comprises a buoy impeller (1), wherein the buoy impeller (1) is provided with a power device (3) through a connecting support plate (2), and comprises a sealing buoy (11) and blades (12), the power device (3) consists of a vertical motor (31), a speed reduction mechanism (32) and a rotary flange (33), the integral blade (12) is in an L shape, and is uniformly provided with a plurality of water division holes (6) and a water division groove (7), and the blades (12) are fixedly and adjustably connected with the sealing buoy (11) by virtue of the blade bottom plate (13). The aerator not only solves the problems of large size of aeration equipment and inconvenient production, transportation, assembly and use as the traditional impeller aerator uses the bearing devices, such as floating balls, to bear the power device of the aerator, but also effectively solves the problems of single type of traditional blade and unable aeration, water tillage and surging.

Owner:江苏现代渔业装备科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com