Sample package dyeing machine

A technology for dyeing machines, cheese yarns, applied in the direction of processing textile material dyeing devices, textile processing machine accessories, liquid/gas/vapor yarn/filament processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

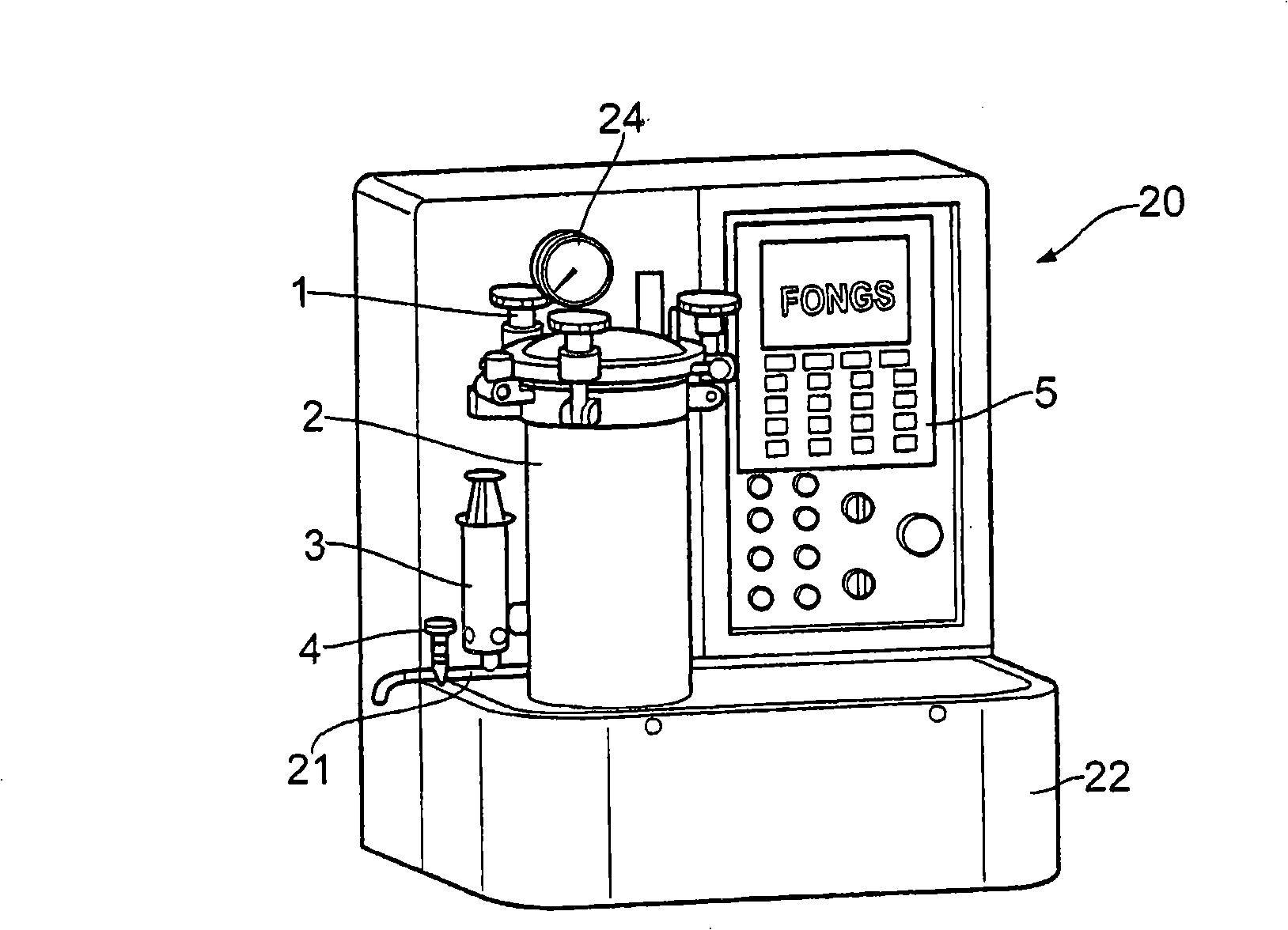

[0026] figure 1 An external perspective view of a sample cheese dyeing machine according to an embodiment of the present invention is shown. The dyeing machine has a small overall size suitable for dyeing a single sample package weighing less than 1.2 kg of a standard package. The dyeing machine can be easily installed in a laboratory, so it is very convenient. More importantly, the dyeing machine is designed to operate and function in the same manner as a mass production cheese dyeing machine so that the mass production dyeing mechanism and liquor ratio can be replicated. As a result, samples of dyed yarns can be produced that can be accurately reproduced on a mass production scale.

[0027] Specifically, the dyeing machine was configured to operate with a liquor ratio of about 1:6. This is the liquor ratio generally used in cheese dyeing for mass production. The liquor ratio is the ratio of the amount of liquor required to produce the desired dyeing result to the amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com