A small all-electric trenchless horizontal directional drilling rig

A horizontal directional drilling rig, all-electric technology, applied in directional drilling and other directions, can solve the problems of high price and complex structure, and achieve the effects of easy operation, reducing work volume and improving construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

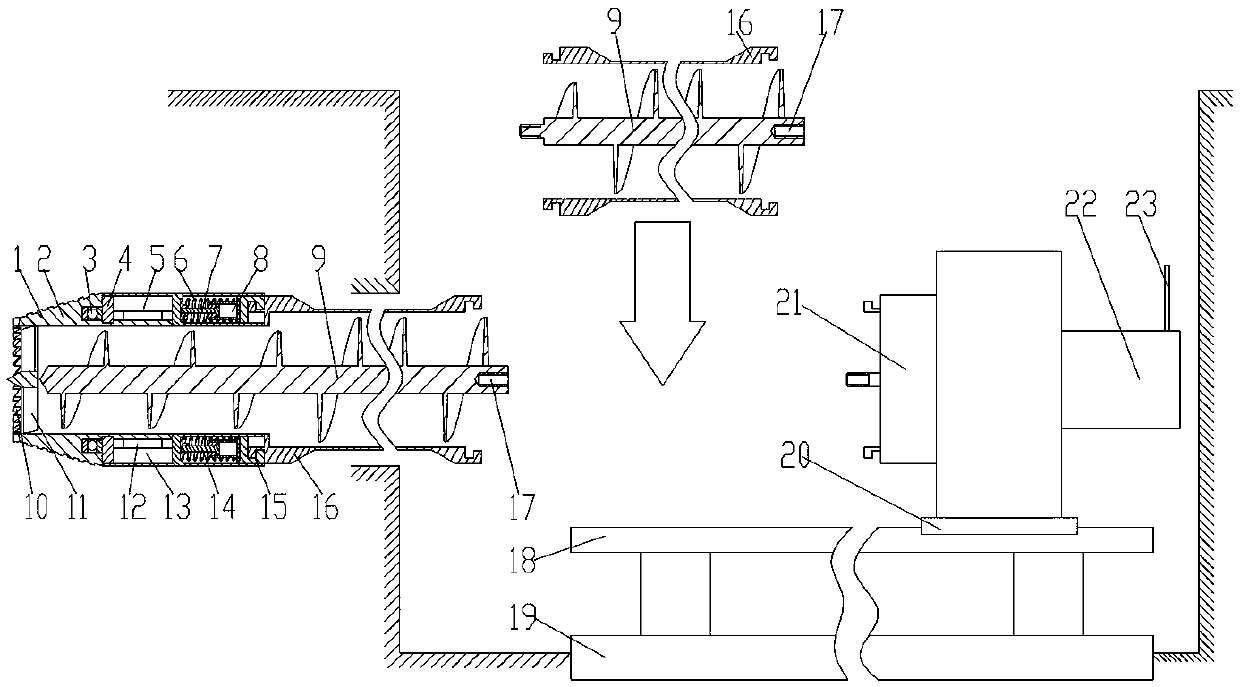

[0024] Embodiment 1, the present invention includes a cutting drill bit 1, a drill bit rotary cutting drive device, a buffer device, a post-soil screw conveying device, and a drill pipe jacking and dragging device. The cutting drill bit 1 is a hollow drill bit, and the cutting drill bit cone 2 is provided with a Drill bit rotary cutting drive device, the drill bit rotary cutting drive device is connected with a buffer device, the rear screw conveying device for soil is installed on the cutting bit 1 axis, and the rear end of the rear screw conveying device for the last section of soil is connected with the drill pipe jacking and dragging device , the drill pipe is jacked into the pullback device and connected to the power supply. The rotary cutting drive device of the drill bit completes the rotary drive of the cutting bit 1; when the cutting bit 1 encounters poor ground conditions, excessive resistance or unevenness, the buffer device plays a role of buffering; the rear screw ...

Embodiment 2

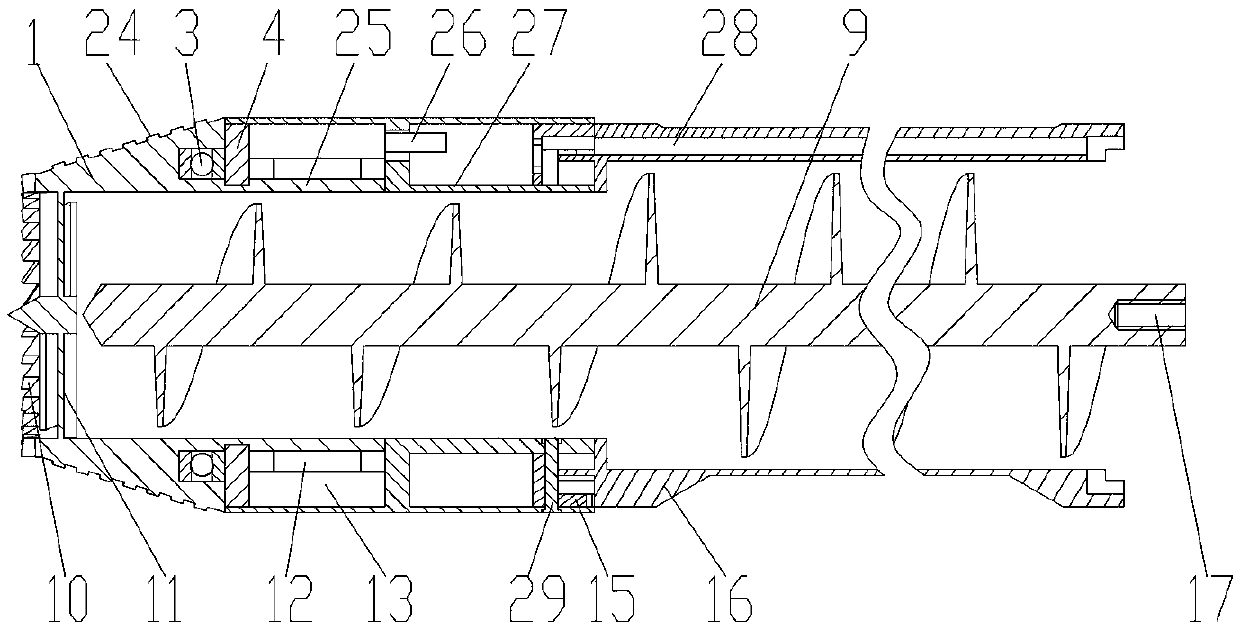

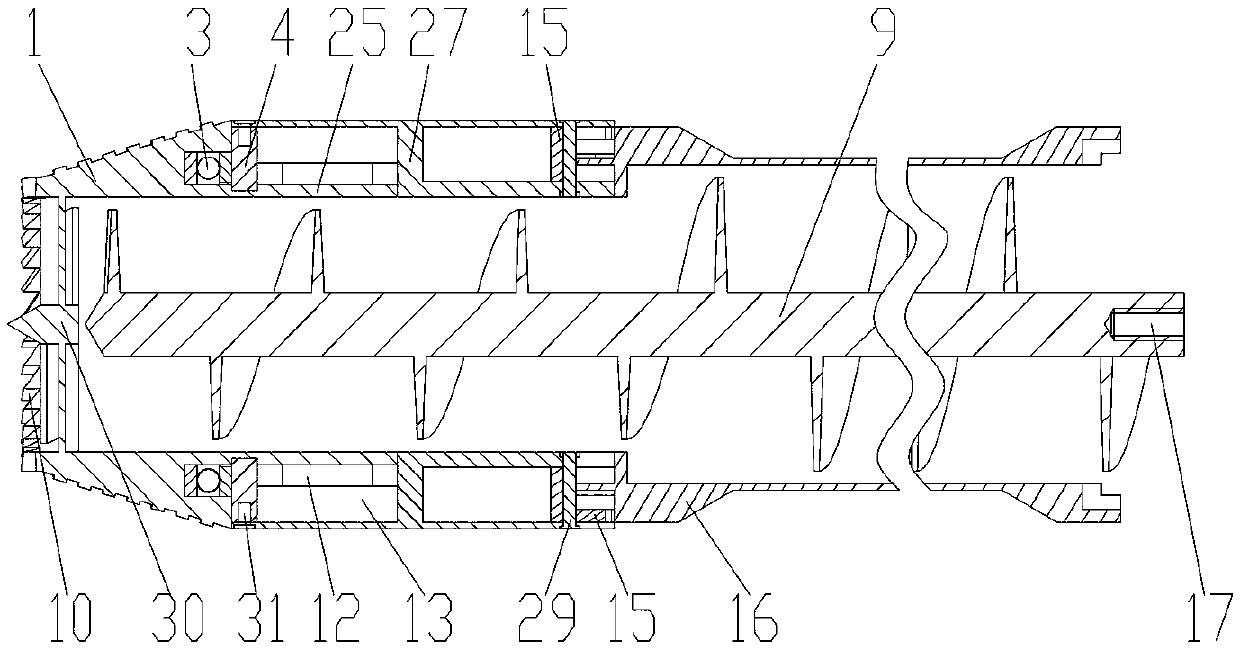

[0025]Embodiment 2, the middle of the cutting bit 1 is circular and hollow, including the cutting bit cone 2 of the front section, the helical cutting edge 24, the cutting bit outer circular cutter 10, the cutting bit inner cutter 11 and the cutting bit insert of the rear section. Barrel 25, the front end axis is provided with a cutting drill center cone 30, the cutting drill center cone 30 is fixedly connected with the cutting drill cone 2 through a bracket, the helical cutting edge 24 is arranged on the outer wall of the drill cone 2, and the cutting drill The outer circular cutter 10 is a tooth-shaped cutter integrally formed with the cutting drill cone 2, or a tapered scraper, which is evenly distributed and welded on the circumference of the front end of the cutting drill cone 2; the cutting drill inner cutter 11 is more than two The helical blades uniformly dispersed and welded on the central cone 30 of the cutting drill bit, the helical blades are suitable for areas that...

Embodiment 3

[0026] Embodiment 3, the drill rotary cutting driving device includes a thrust ball bearing 3 and a frameless motor 5, a front partition 4 is arranged between the cutting drill 1 and the frameless motor 5, and the front partition 4 is fixed on the shield by screws 31 27, the frameless motor 5 is fixedly installed on the front part of the shield 27 through the front partition 4, and the thrust ball bearing 3 is installed between the cutting drill 1 and the front partition 4 to provide its axial thrust; the frameless motor 5 is a hollow motor, including a frameless motor inner rotor 12, a frameless motor outer stator 13 and a frameless motor wire 26; the rear end cutting drill insert 25 of the cutting drill 1 is fixed inside the frameless motor inner rotor 12 by adhesive, The frameless motor 5 directly drives the cutting drill bit 1 to rotate. refer to Figure 1 to Figure 9 , and the rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com