Gear type compressor

A gear type and compressor technology, applied in the field of compressors, can solve problems such as bearing damage, achieve the effects of reducing vibration and noise, improving assembly efficiency, and improving coefficient of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

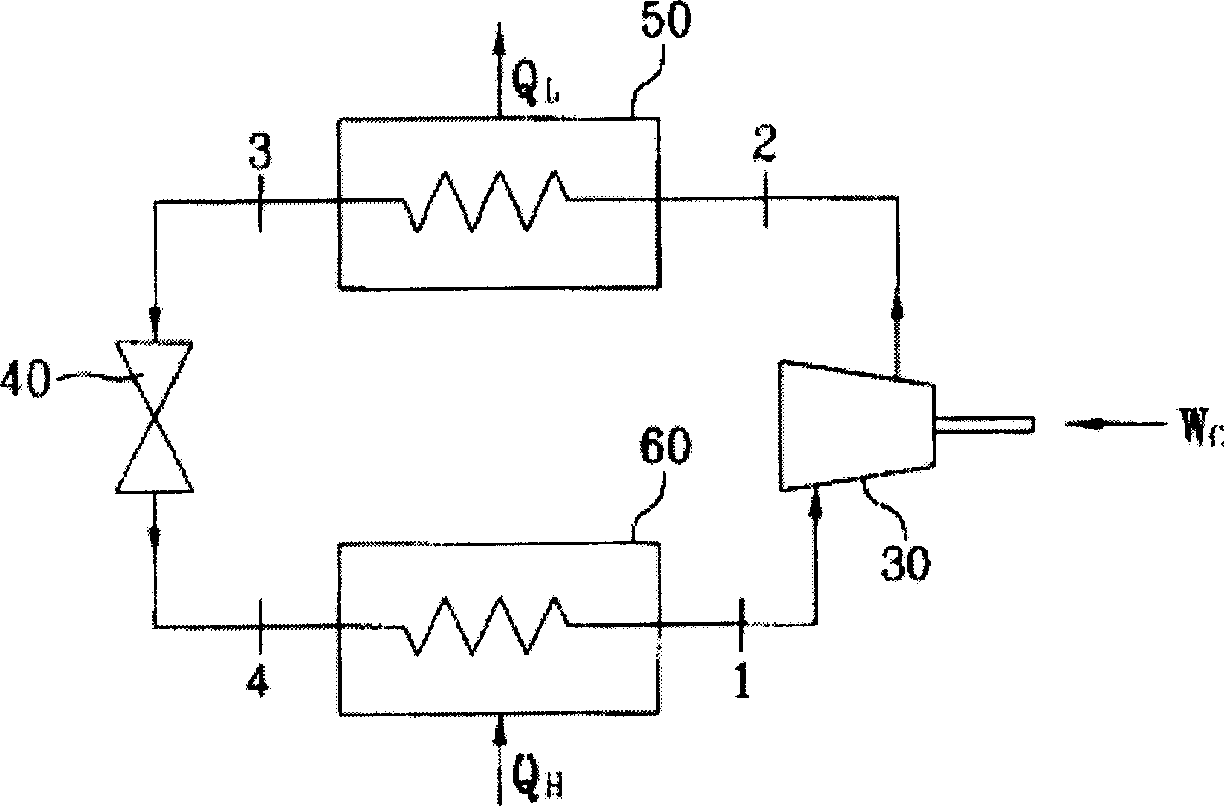

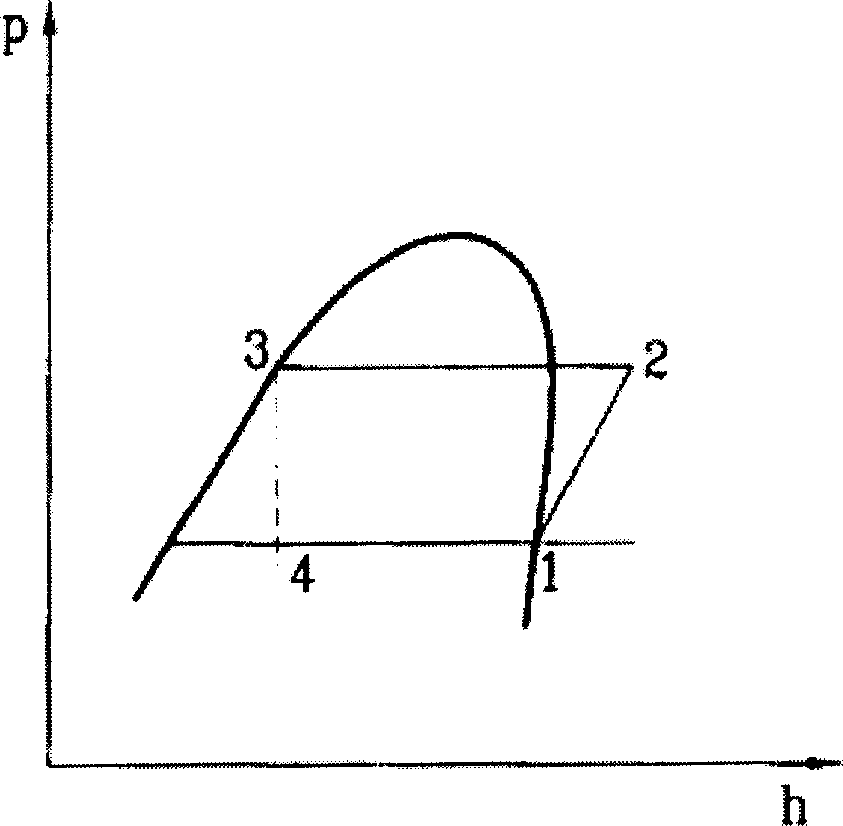

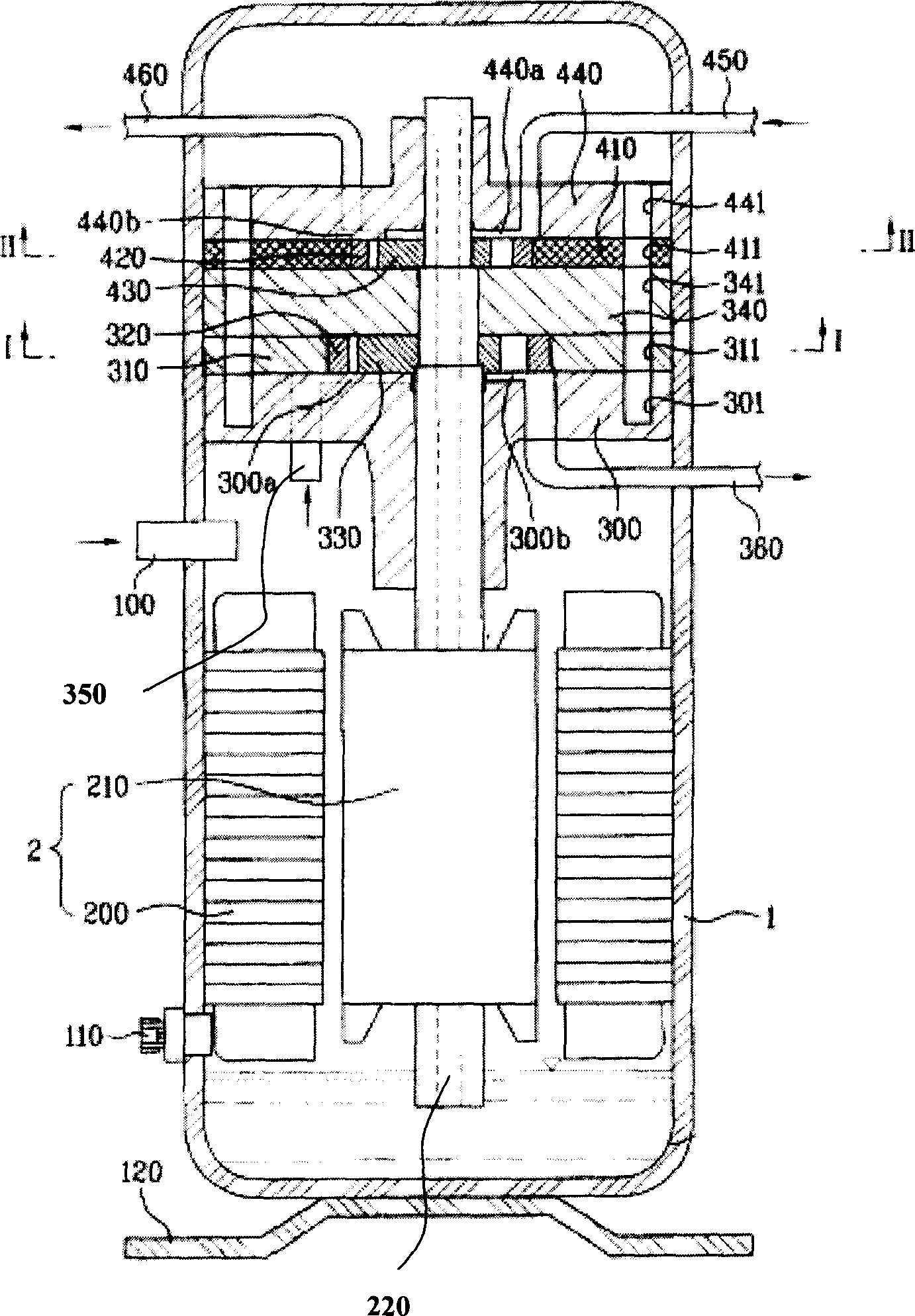

[0046] Such as Figure 3 to Figure 5 As shown, the gear compressor provided by the present invention includes a casing 1 , a driving part 2 , a gear compression part 3 and a gear expansion part 4 . The casing 1 has a certain internal space. The drive unit 2 is provided inside the casing 1 . The gear type compression part 3 uses the power provided by the driving part 2 to compress the refrigerant discharged from the evaporator 6 . The refrigerant discharged from the gear-type compression part 3 flows through the condenser 5 and then flows into the gear-type expansion part 4 inside the compressor for expansion. The driving part 2 is a motor composed of a stator 200 arranged on the inner wall of the housing 1 and a rotor 210 arranged at the center of the stator 200 . After the power is turned on through the power terminal 110 , the rotor 210 can rotate. One side of the casing 1 is provided with a suction pipe 100 for sucking the refrigerant into the inside. And the lower par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com