Method and device for synthesizing 3,4-dioxymethylene mandelic acid by enhanced emulsification

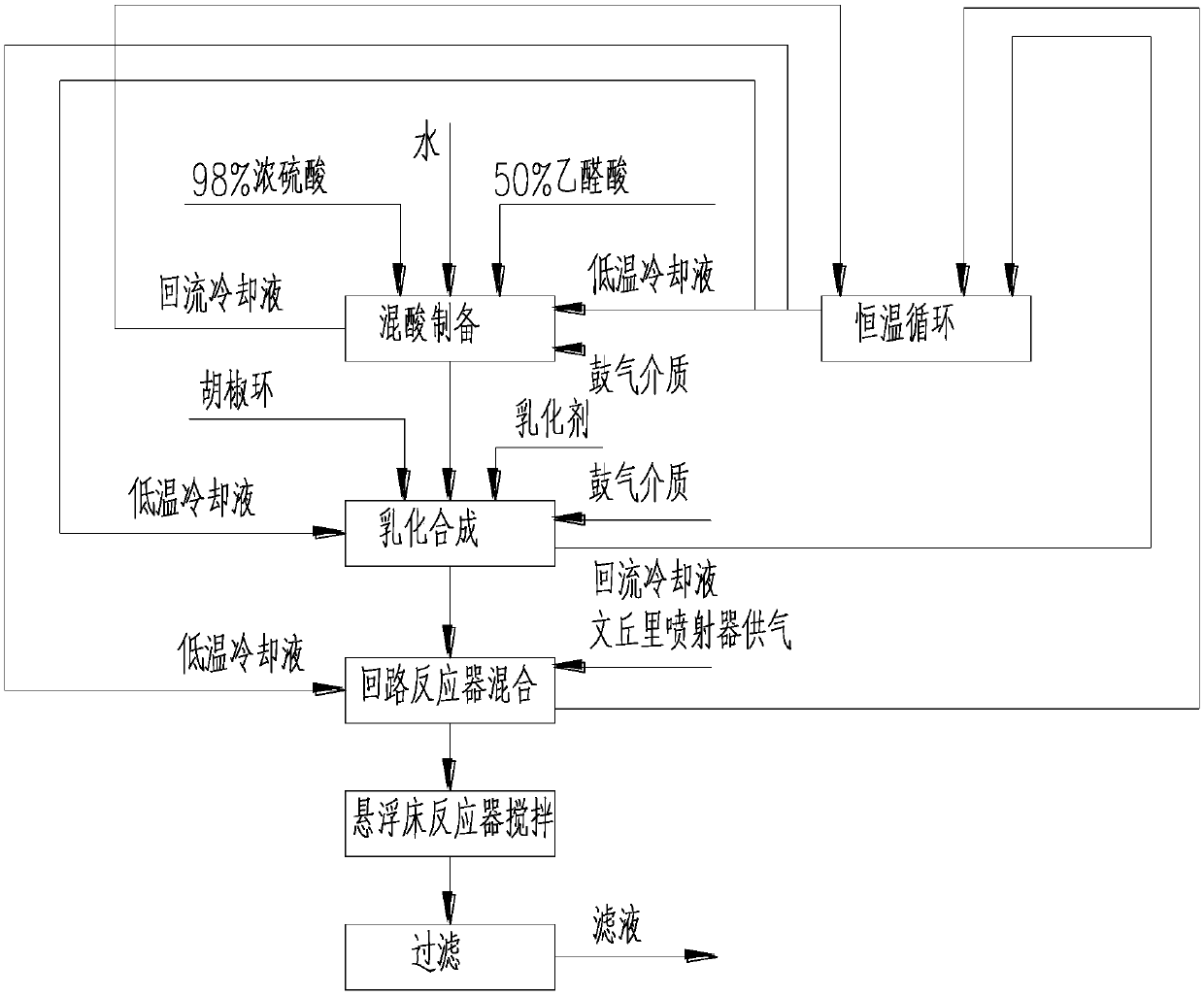

A methylenedioxybenzene and glycolic acid technology, applied in the field of chemical engineering, can solve the problems of insufficient reaction, low mass transfer efficiency, poor fluidity, etc., achieve simple and easy product separation process, and improve product purity and yield , Increase the effect of heat and mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] A method for enhancing emulsification synthesis of 3,4-methylenedioxymandelic acid, carried out according to the following steps:

[0078] Step 1, the mixture of 10g of water and 160g of 50wt% glyoxylic acid aqueous solution was stirred at a constant temperature, the temperature of the constant temperature stirring was -25°C, and the stirring rate was 400rpm;

[0079] Step 2, after starting to stir, add 98wt% concentrated sulfuric acid dropwise to the mixture at a rate of 7g / min per minute, add 140g of the total amount of 98wt% concentrated sulfuric acid dropwise, the stirring temperature is -25°C, and the stirring rate is 400rpm ;

[0080] Step 3, when all the 98wt% concentrated sulfuric acid is added dropwise, continue to stir for 30 minutes, and the stirring temperature is -25°C;

[0081] Step 4, add 3,4-methylenedioxymandelic acid and benzyltriethylammonium chloride to the solution after step 3 is completed, add 4g of 3,4-methylenedioxymandelic acid , add the amou...

Embodiment 2

[0089] A method for enhancing emulsification synthesis of 3,4-methylenedioxymandelic acid, carried out according to the following steps:

[0090] Step 1, the mixture of 10g of water and 200g of 50wt% glyoxylic acid aqueous solution was stirred at a constant temperature, the temperature of the constant temperature stirring was -30°C, and the stirring rate was 430rpm;

[0091] Step 2, after starting to stir, add 98wt% concentrated sulfuric acid dropwise to the mixture at a rate of 9g / min per minute, add 150g of the total amount of 98wt% concentrated sulfuric acid dropwise, the stirring temperature is -28°C, and the stirring rate is 430rpm ;

[0092] Step 3, when all the 98wt% concentrated sulfuric acid is added dropwise, continue to stir for 30min, and the stirring temperature is -28°C;

[0093] Step 4, add 3,4-methylenedioxymandelic acid to the solution after step 3 is completed, and add 9 g of 3,4-methylenedioxymandelic acid;

[0094] Step 5, emulsify the solution after step...

Embodiment 3

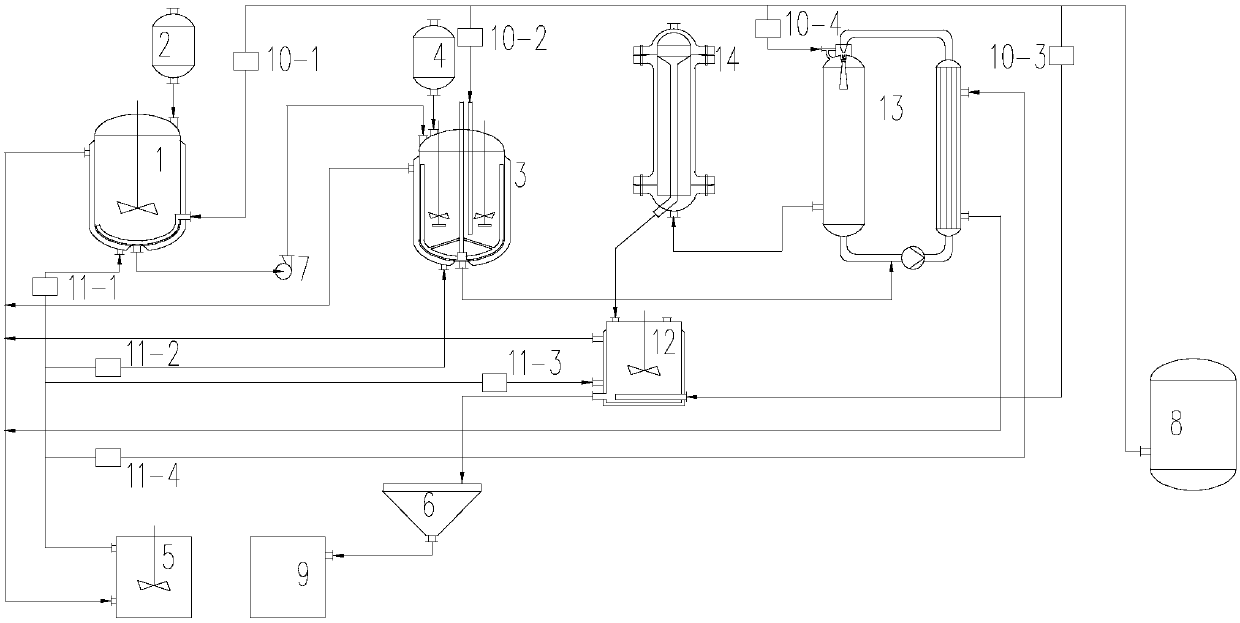

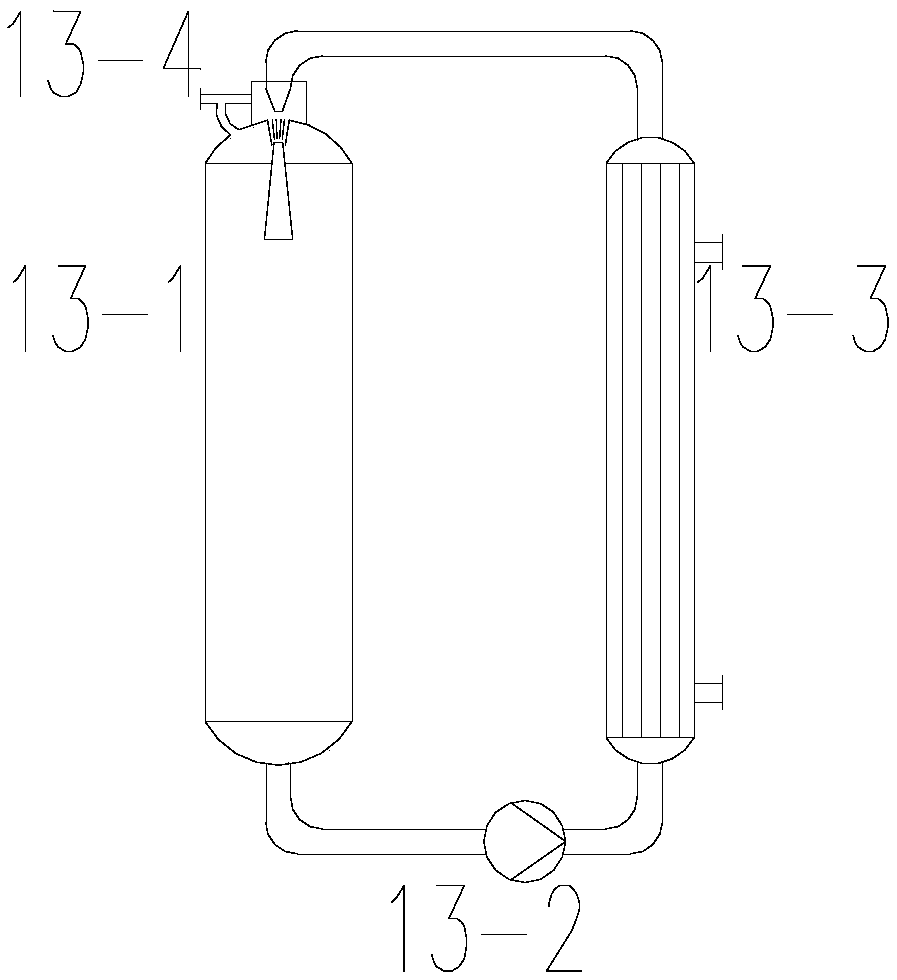

[0101] A device for enhancing emulsification synthesis of 3,4-methylenedioxymandelic acid, comprising a jacketed distributor stirring tank, a sulfuric acid metering tank, a jacketed distributor emulsification tank, a jacketed distributor product stirring tank, Loop reactor with Venturi ejector, circulating suspended bed reactor, pepper ring metering tank, constant temperature tank, filtration equipment, feed pump, gas storage tank, filtrate tank, the outlet of the sulfuric acid metering tank is stirred with jacketed distributor The still pipes are connected, the sulfuric acid metering tank is arranged above the jacketed distributor stirring tank, and the outlet of the circulating liquid in the constant temperature tank is respectively connected to the jacket inlet and the jacket of the jacketed distributor stirring tank by pipelines. The jacket inlet of the emulsification kettle of the type distributor, the heat exchange medium inlet of the heat exchanger and the jacket inlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com