Ultrasonic-assisted powder forming method in a fluid environment

An ultrasonic-assisted, powder forming technology, applied in the direction of manufacturing tools, presses, etc., can solve the problem of large residual stress and elastic aftereffect of powder forming parts, difficulty in controlling the breakage rate of friction powder particles, and compact density. and mechanical properties, etc., to achieve high-quality molding preparation, improve fluidity and filling performance, and improve the uniformity of density distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] An ultrasonic-assisted powder forming method in a fluid environment, comprising the following steps:

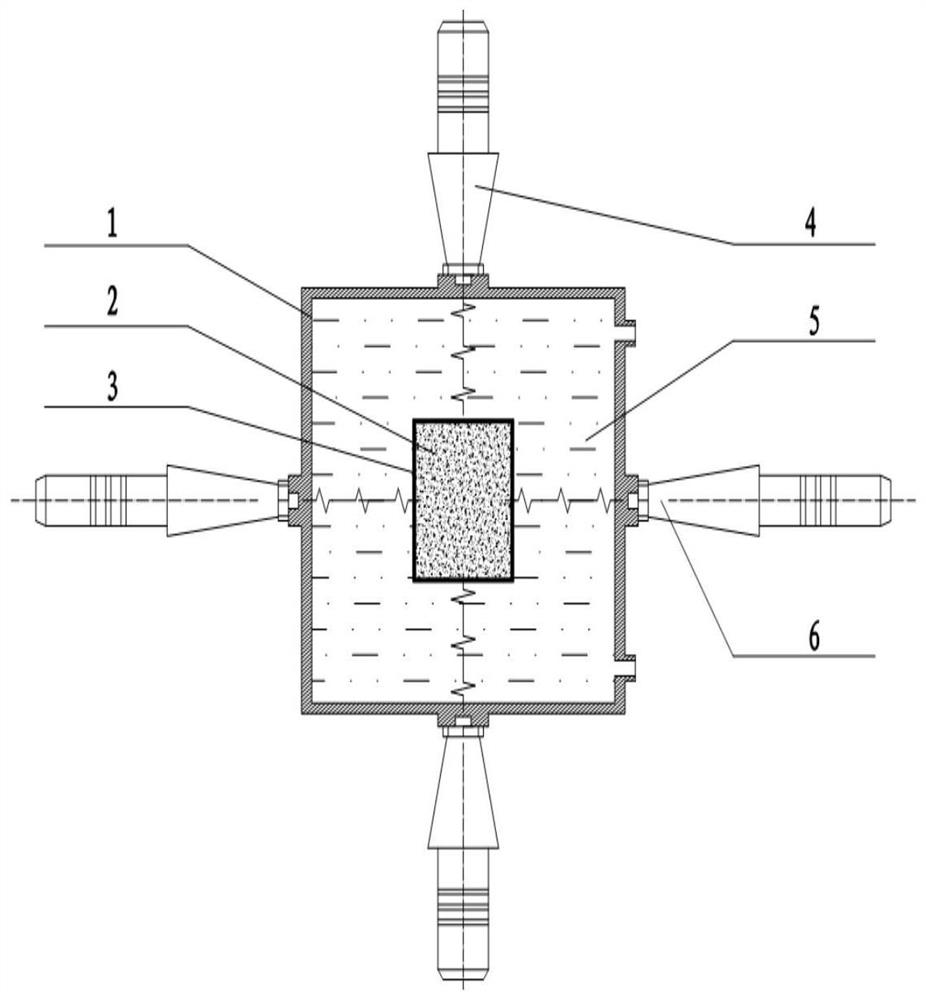

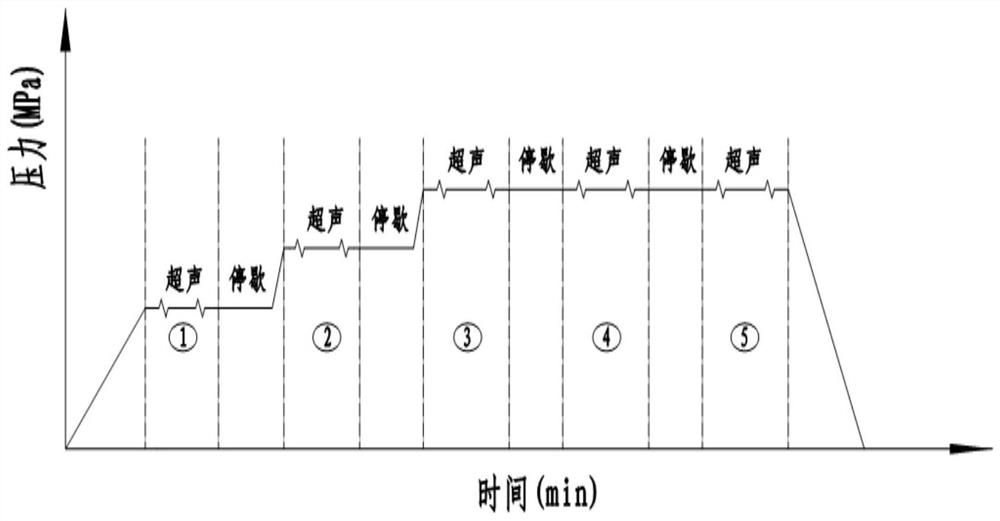

[0019] (1) Set up powder molding equipment, including high-pressure airtight containers, jackets, axial ultrasonic transducers and radial ultrasonic transducers. The directional ultrasonic transducer is used to generate axial ultrasonic vibration to push the powder material to produce periodic up and down motion, and the radial ultrasonic transducer is used to generate radial ultrasonic vibration to push the powder material to produce periodic left and right motion; ( 2) Put the powder particles into the package, and put the package containing the powder particles into a closed container; (3) Apply hydrostatic pressure, apply isotropic hydrostatic pressure to the package through the fluid medium, and the package shrinks , which drives the powder particles contained inside to move to the center and squeeze and shrink; after applying hydrostatic pressure, the powder part...

Embodiment 2

[0021] In order to investigate the effect of ultrasound on the molding of granular materials in a static fluid medium environment, the hard granular material M01 and the soft granular material M02 were used for compression molding. The results showed that at 80MPa and room temperature, the Granular materials M01 and M02 can hardly be condensed into shape; after applying ultrasound, the harder granular material M01 is formed by about 30mm column segments, and there are a large number of agglomerated agglomerates, while the softer granular material M02 has achieved almost complete Forming, indicating that ultrasound can significantly promote the formation of granular materials in a fluid medium environment.

Embodiment 3

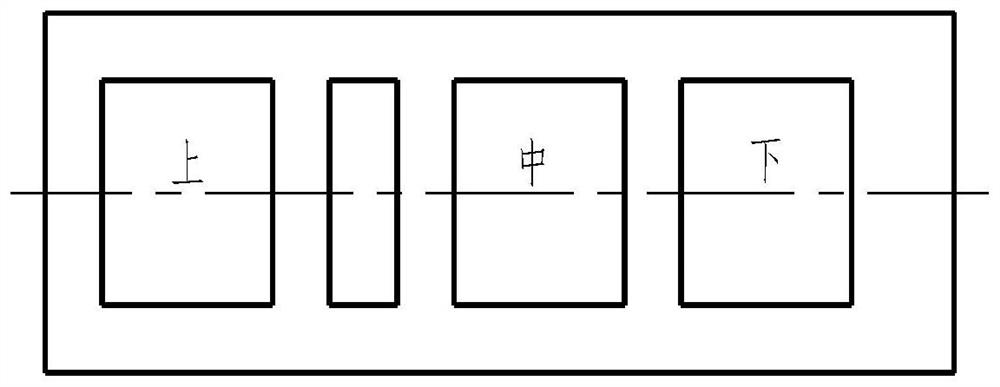

[0023] Using the soft powder material M03 as raw material, the pressed blank was prepared by ultrasonic-assisted powder hydrostatic pressure molding process, according to image 3 At the sampling position, a φ20mm×20mm sample was extracted, and its apparent density was measured, such as Figure 4 It is shown that under the action of 80MPa hydrostatic pressure, the application of ultrasound can increase the compact density by about 1.25% (from 1.634g / cm 3 to 1.654g / cm 3 ); under the action of 130MPa hydrostatic pressure, the application of ultrasound can increase the compact density by about 2.15% (from 1.739g / cm 3 to 1.776g / cm 3 ). The above results show that ultrasound can promote the increase of powder material molding density under the condition of fluid medium environment.

[0024] In the process of forming powder particles, the patent of the present invention applies longitudinal vibration to the powder through the axial transducer, and applies transverse vibration to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com