Contraposition double-eccentric-wheel sliding groove push-pull reciprocating compressed air pressurizing homogeneity compression ignition internal combustion engine

A technology of double eccentric wheel and sliding groove, applied in the direction of machine/engine, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to clarify the purpose of the present invention more clearly, the technical innovation advantages and beneficial effects of generations of the present invention are presented, so as to make the content of the present invention more concise and easy to understand. Below in conjunction with the technical scheme of the specific embodiment of the present invention, further describe in detail:

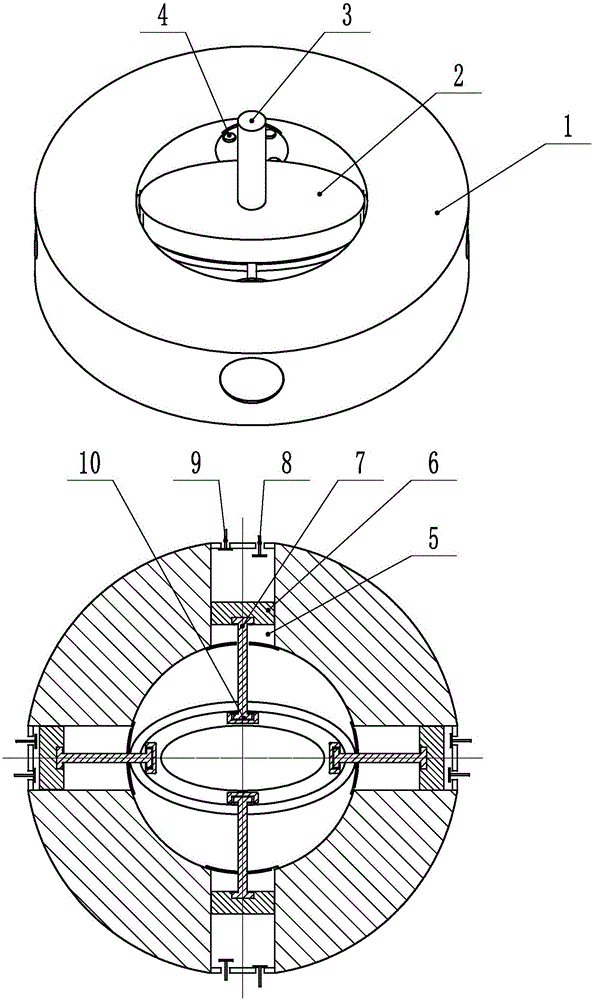

[0022] Such as figure 1 As shown in the schematic diagram of the embodiment, it is an air compressor driven by opposing double eccentric sliding grooves or a scavenging pump for an internal combustion engine. cover (such as figure 1 1, 2, 3, 4), the air pump cylinder, piston, connecting rod, exhaust valve, intake valve and connecting rod sliding bearings drive the piston to reciprocate in the sliding groove of the double eccentric wheel in a sliding push-pull manner (Such as figure 1 5, 6, 7, 8, 9, 10) in the logo are combined.

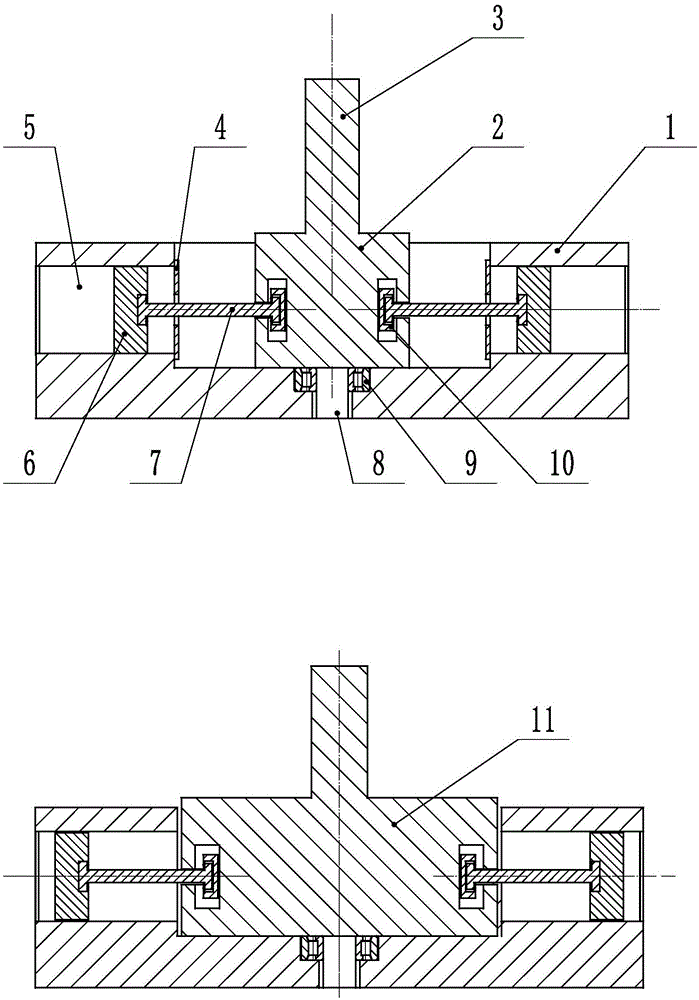

[0023] Such as figure 2 As shown in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com