Light load sliding bearing

A sliding bearing, light-load technology, applied in the direction of bearing components, shafts and bearings, rigid brackets of bearing components, etc., can solve the problems of small oil flow consumption, poor stability, inconvenient installation, disassembly and maintenance, etc. The effect of reduced oil supply, easy disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

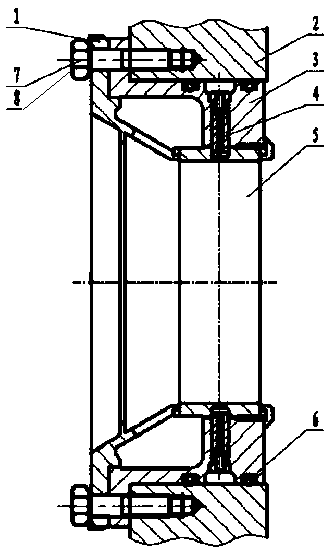

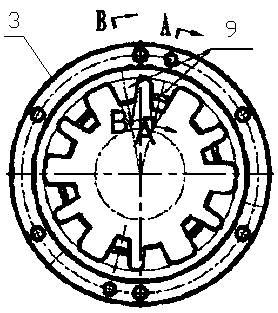

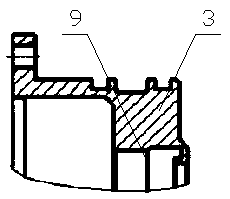

[0016] Referring to each figure, the light-load sliding bearing includes front support 1, casing 2, rear support 3, oil supply pipe 4, bearing bush 5, rubber sealing ring 6, bolt 7 and locking plate 8, and bearing bush 5 is provided with Radial mounting holes and bosses 10, the front support 1 and rear support 3 are provided with hooks, the hooks cooperate with the bosses 10, six tiles 9 are arranged on the bearing bush 5, and the tiles 9 are evenly distributed On the circumferential surface, two adjacent tiles 9 are provided with gap openings, and the middle position of the outer circular surface of each tile 9 forms a tight fit and a clearance fit to the boss and the bearing seat respectively, and the tight fit position is the same as that of the front support 1 The position of the hook on the rear support 3 is at the same radial position, and each tile 9 is provided with a radial hole, and one end of the oil supply pipe 4 is installed in each radial hole, and the other end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com