Plunger lifting mechanism of rotary valve type diaphragm carburetor

A rotary valve type, carburetor technology, applied in the direction of machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The following description is merely exemplary in nature and not intended to limit the disclosure, application or use. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

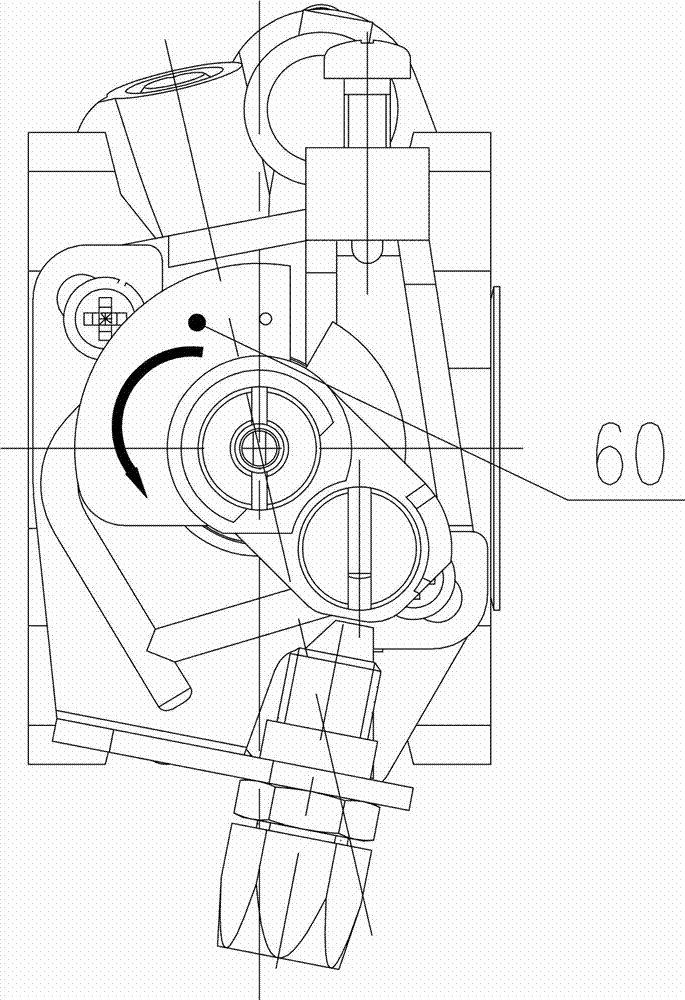

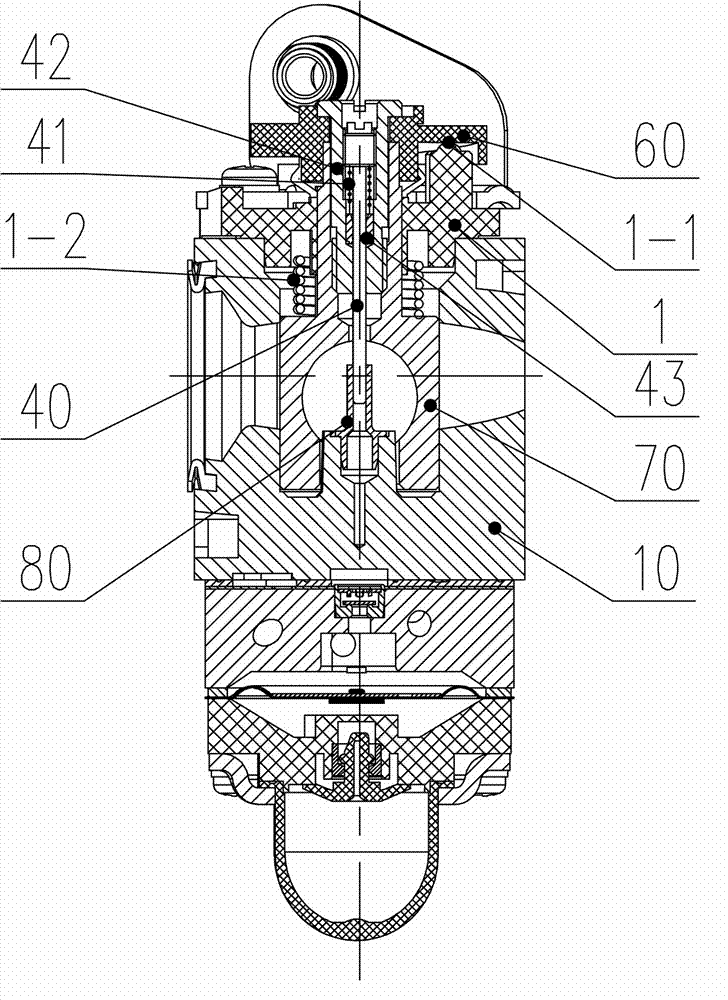

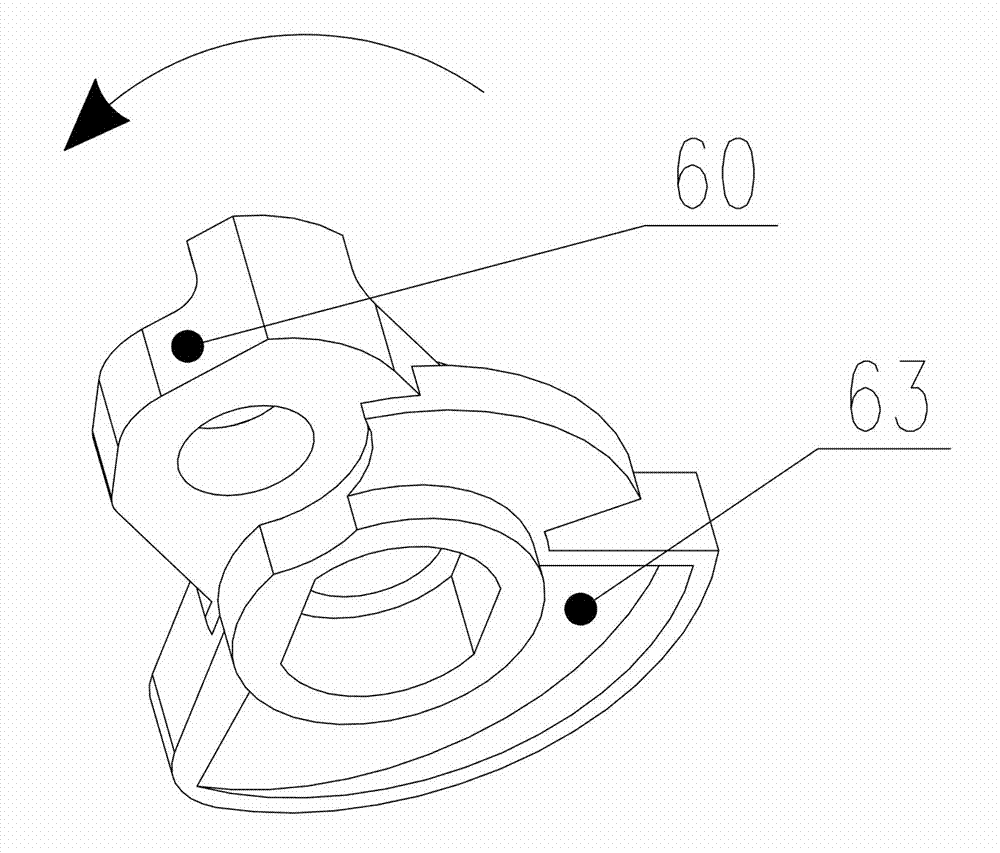

[0054] Referring now to the accompanying drawings, Figure 4 , Figure 5 , Image 6 , Figure 9 The outline structure diagram of the carburetor of the present invention is described. Carburetor has body 10, middle body 20, lower body 30, middle body 20 one side is equipped with oil return pipe 4 and oil inlet pipe 5, to obtain fuel from the fuel tank of engine, when engine stops working, by oil return pipe 4 The fuel in the oiler returns to the fuel tank of the engine; the bottom of the lower body 30 is equipped with an oil cup 3 . A limiting groove 13 is formed in an inner cavity (not marked) of the body 10 , and the limiting groove 13 is used for fixing the cam 60 . The top of the main body 10 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com