Refrigerator compressor and lubricating-oil supplying device

A technology for refrigerator compressors and oil supply devices, which is applied to mechanical equipment, machines/engines, and liquid displacement machinery, etc. It can solve the problem of increasing the operating burden of the crankshaft and motor rotor 7, reducing the demand for lubricating oil, and reducing the work efficiency of the compressor and other problems, to achieve the effect of reducing the load of rotation, small oil supply and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

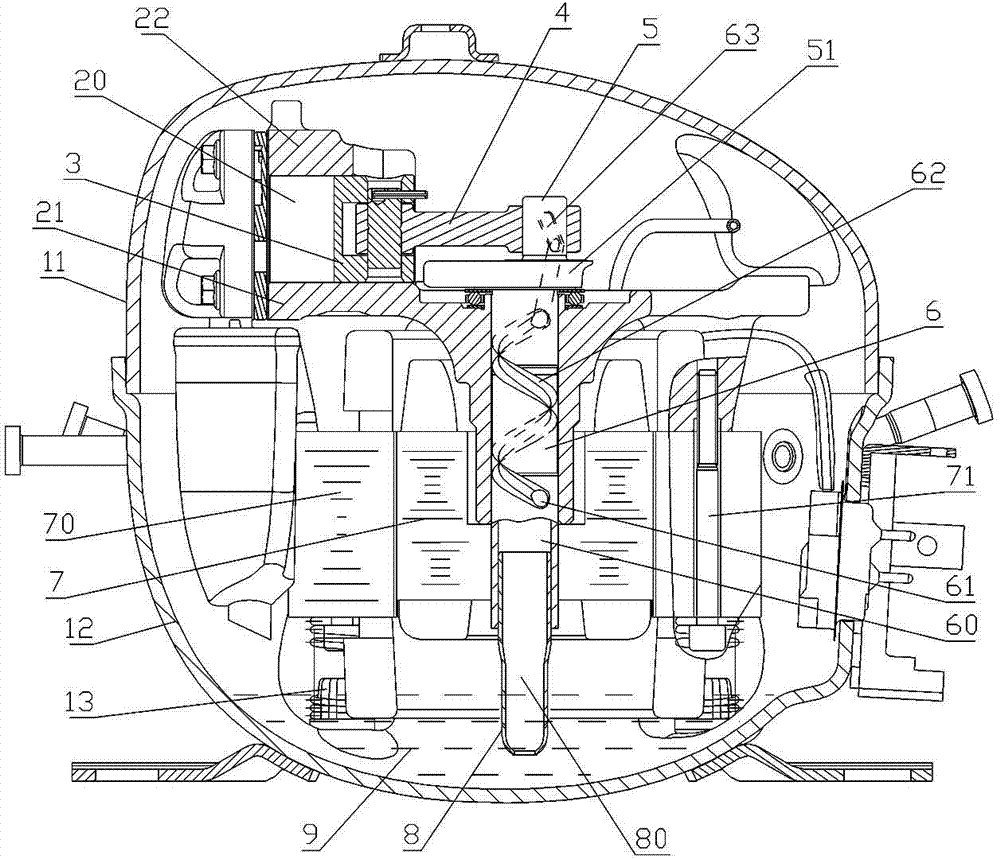

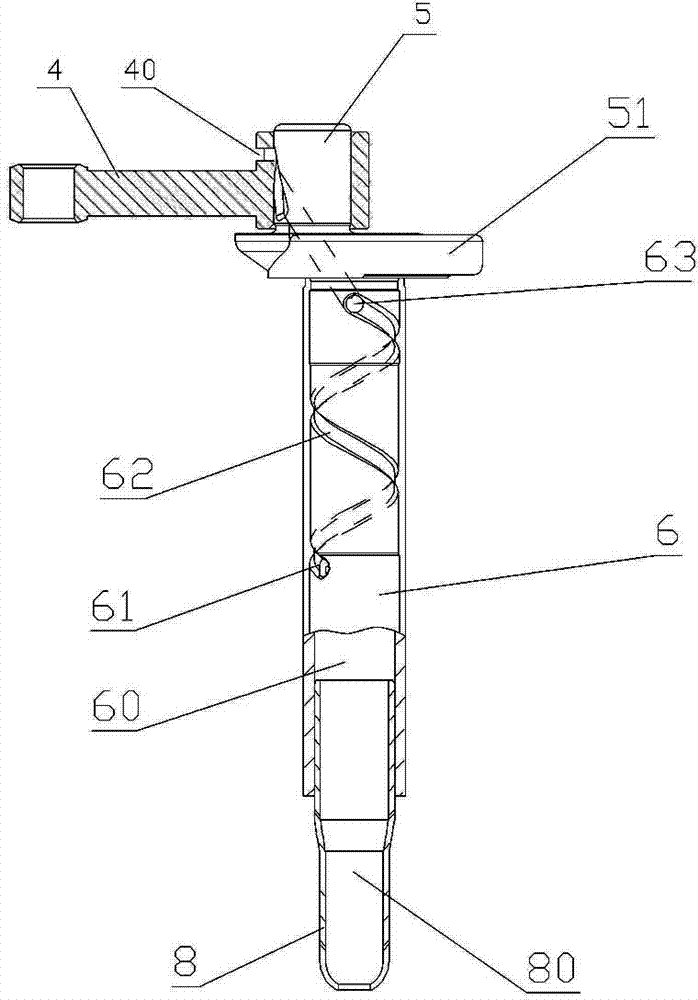

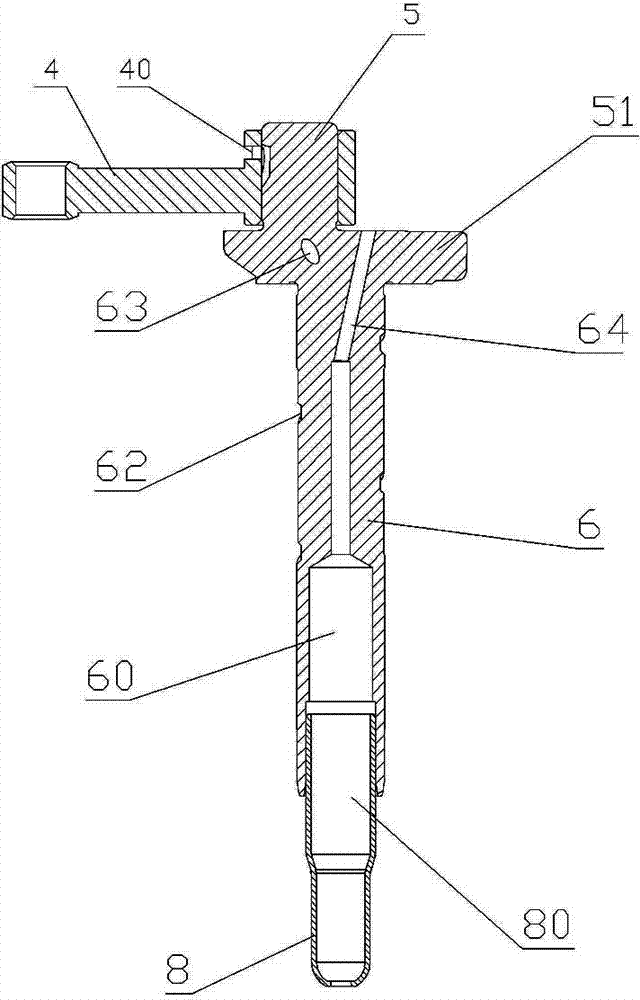

[0031] refer to figure 2 , image 3 , Figure 4 , a lubricating oil supply device for a refrigerator compressor, including a connecting rod 4, a crankshaft and an oil suction pipe 8;

[0032] The crankshaft has a crankshaft part 5, a balance table part 51 and a main shaft part 6 which are sequentially connected in one piece. The middle part is located at the lower end of the outer oil groove 62 and has a middle oil hole 61, and the middle oil hole 61 communicates the outer oil groove 62 with the oil suction inner cavity 60;

[0033] The crankshaft part 5 has an upper oil hole 63 and an inner oil hole 64. The upper oil hole 63 extends through the crankshaft part 5 and the balance table part 51 to the main shaft part 6 and is connected to the upper end of the outer oil groove 62; the inner oil hole 64 passes through the balance The table portion 51 and the main shaft por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com