Intelligent metal plate molding machine

A technology of intelligent sheet metal and forming machines, applied in the direction of presses, metal processing equipment, feeding devices, etc., can solve the problems of workpiece wrinkles, workpiece damage, increase production costs, etc., and achieve the effect of avoiding wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

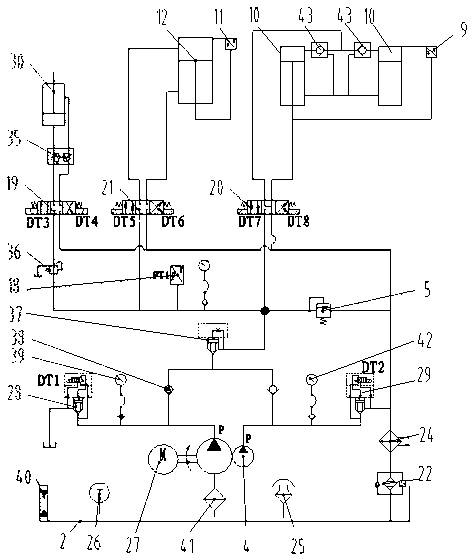

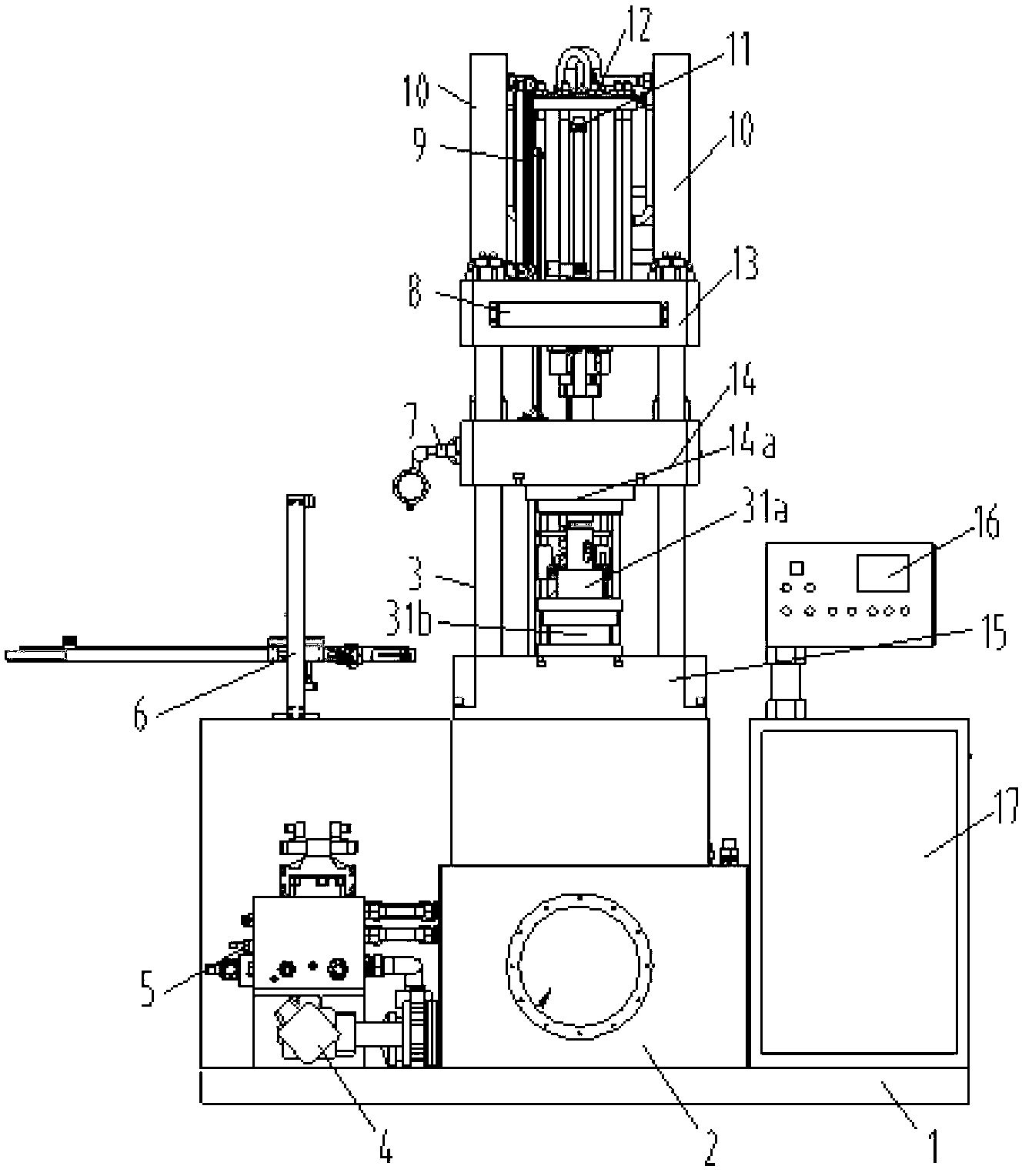

[0039] Such as Figure 1-Figure 3 As shown, the intelligent sheet metal forming machine of the present invention includes: a base 1, a lower template 15, an upper template 13, an ejection cylinder 30 installed below the lower template 15, a plurality of cylinders installed between the lower template 15 and the upper template 13 Upright column 3, be positioned at between upper formwork 13 and lower formwork 15 and be set on the blank-holding formwork 14 on a plurality of upright columns 3, be installed on the forming oil cylinder 12 of upper formwork 13 top and be symmetrically located at the multiple sides of forming oil cylinder 12 Crimping oil cylinder 10, and crimping and locking devices 32 respectively sleeved on a plurality of columns 3.

[0040] Preferably, the number of columns 3 used in the present invention is four, and the number of edge-holding oil cylinders 10 is two, and the two edge-holding oil cylinders 10 are symmetrically arranged on both sides of the forming oi...

Embodiment 2

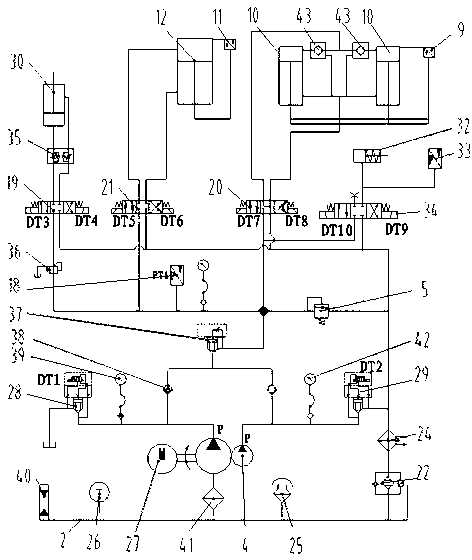

[0064] The intelligent sheet metal forming machine in this embodiment, in addition to including all components in Embodiment 1, such as Figure 4 , Figure 5 , Figure 8 , Figure 9 As shown, it also includes: four blanking locking devices 32 respectively sleeved on the four columns 3 between the upper template 13 and the blanking template 14, and the four blanking locking devices 32 are used for two When the crimping oil cylinder 10 performs the crimping action, the crimping template 14 and the four columns 3 are locked according to the oil pressure signal generated by the pressure of the oil supply circuit of the two crimping cylinders 10 detected by the first pressure sensor 18 . When the blank holder die 10a is closed with the mold, and the blank holder force of the blank holder cylinder 10 does not meet the requirements, the blank holder locking device 32 of this embodiment locks the blank holder template 14 and the column, so that the press of the molding machine Boun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com