Working medium contact cooling system for computer and data center heat radiation

A data center and cooling system technology, applied in computing, electrical digital data processing, digital data processing components, etc., can solve the problems that the air conditioning system cannot solve local high heat, large heat generation of a single cabinet, unreasonable air flow organization, etc., to achieve Lower temperature, simple structure, and mature manufacturing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

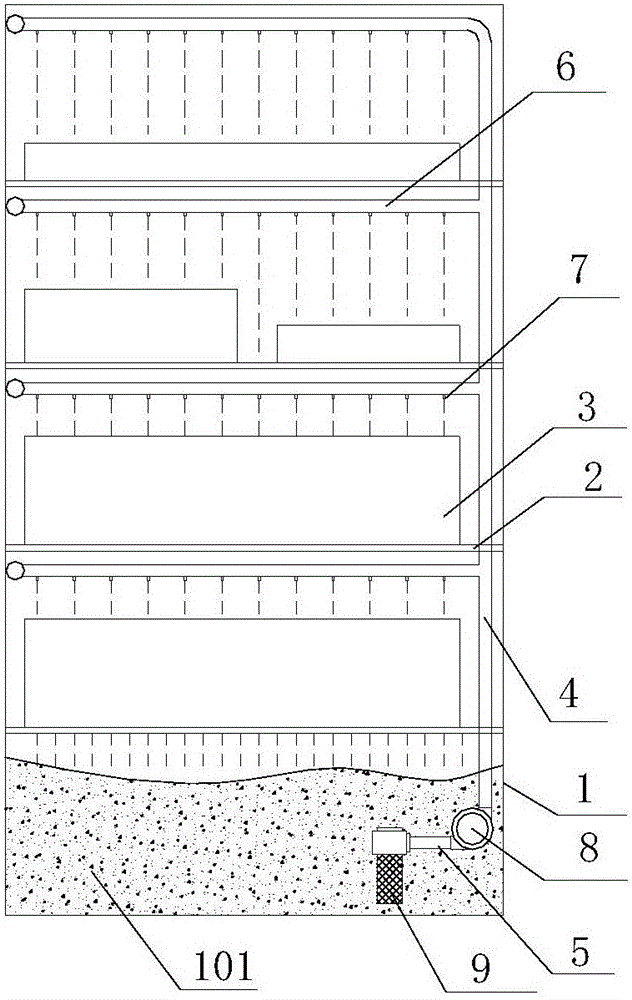

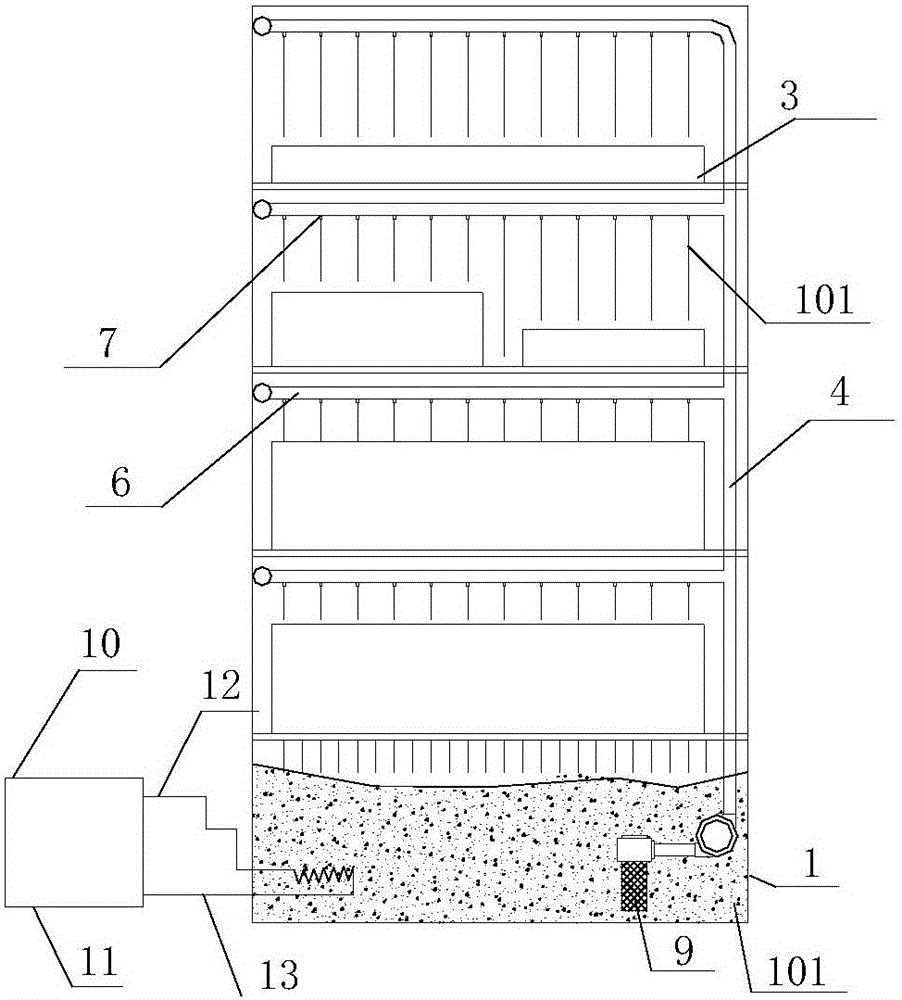

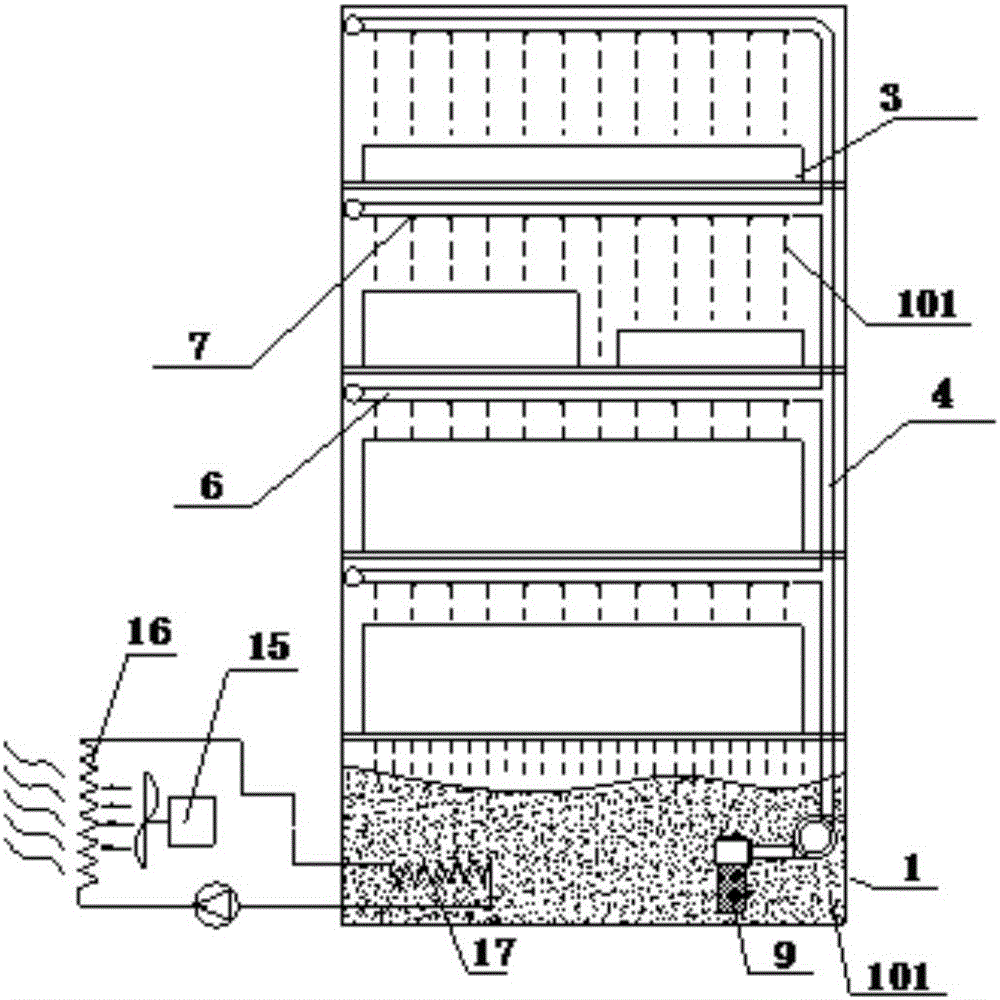

[0040] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0041] like Figures 1 to 5 As shown, a working medium contact cooling system for heat dissipation of computers and data centers includes a server cabinet, which is generally arranged vertically; a liquid working medium box 1, which is located in the The bottom of the server cabinet; multi-layer parallel and horizontally arranged hollows or partitions with backflow channels, the server components are installed on the partitions 2; the manifold liquid distributor 4, the manifold liquid distributor 4 is vertical Arranged and communicated with the liquid working medium tank 1 through the main pipeline; multiple liquid working medium spray pipes 6, a plurality of liquid working medium spray pipes 6 are evenly arranged w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com