Variable-gradient fractal lattice sandwiched reinforcement phase change heat sink

A technology for enhancing phase and phase change heat, which is applied in the short-term or periodic heat dissipation control and the instantaneous field of electronic equipment, and can solve the problems of low utilization rate of enhanced heat transfer materials, limitation of comprehensive heat transfer efficiency, and high utilization rate of enhanced heat transfer materials. , to achieve the effect of improving the comprehensive heat transfer efficiency, improving the comprehensive heat transfer efficiency, and high comprehensive heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

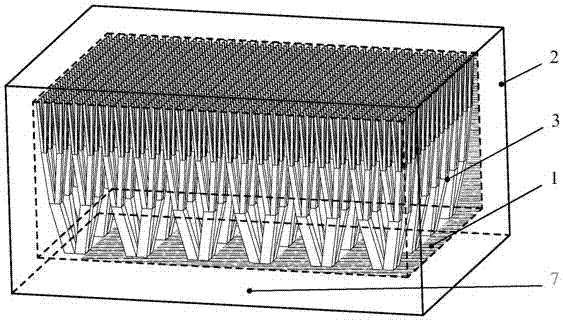

[0029] According to the heat dissipation performance index requirements of the phase change heat sink and the allowable size and weight, the external dimensions, inner cavity size, and the thickness of the thermal diffusion bottom plate 7 and the surrounding frame and cover plate of the phase change heat sink are determined by calculation. The phase change heat sink in this embodiment The overall size of the heat sink is 38mm (length) × 26mm (width) × 19mm (height), the inner cavity size is 36mm (length) × 24mm (width) × 15mm (height), the thickness of the thermal diffusion bottom plate (7) is 3mm, and the surrounding And the wall thickness of the top cover plate is 1mm, and 24 variable gradient fractal lattice sandwich structure sample units are evenly distributed on the inner surface;

Embodiment 2

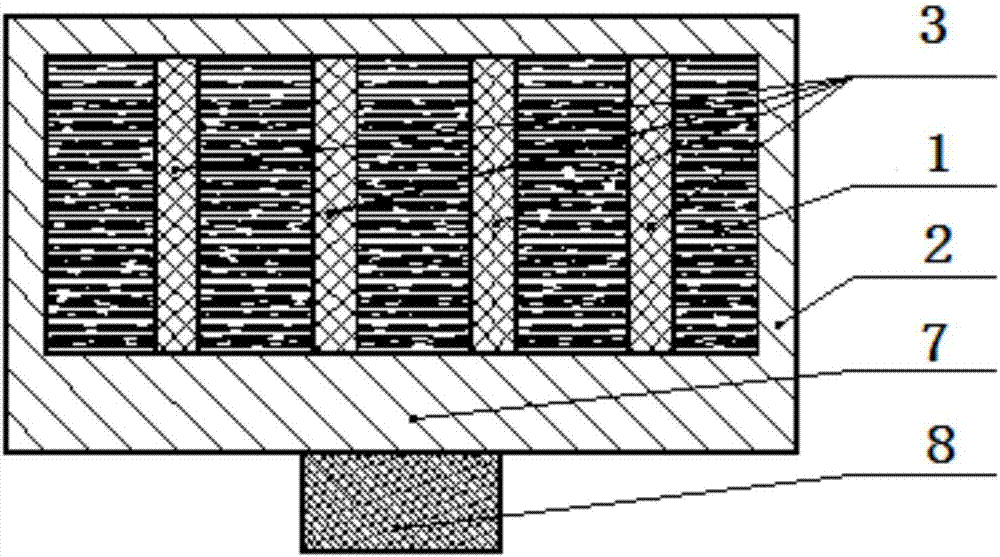

[0031] According to the heat dissipation performance index requirements of the phase change heat sink, determine the proportion of strengthening materials and phase change materials in the phase change heat sink, and determine the cross-sectional area of the enhanced heat transfer structure 3 through calculation. The calculation formula is: cross-sectional area of the enhanced heat transfer structure = phase Cross-sectional area of variable heat sink × proportion of strengthening material. According to calculations in this example, the proportion of strengthening materials is 1 / 9 (about 11%), and the proportion of phase change materials is 8 / 9 (about 89%). Therefore, the cross-sectional area of the enhanced heat transfer structure is 96mm 2 ;

Embodiment 3

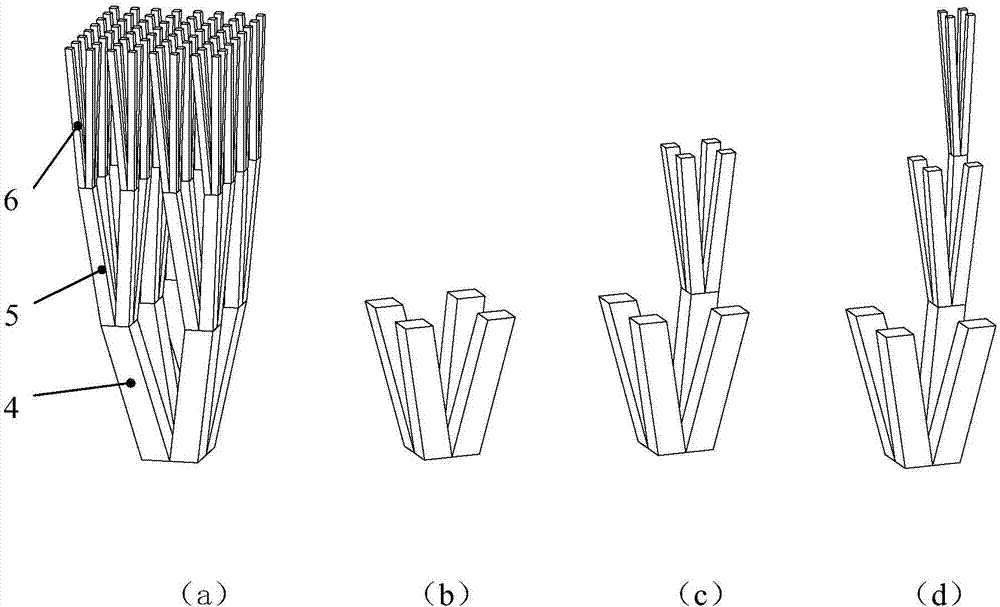

[0033] The graded gradient is determined according to the thickness of the phase change heat sink, which can be divided into several levels. In this embodiment, the number of graded gradients is determined to be 3, and the height of each gradient is 5mm;

[0034] The layout, shape, and size of the first-stage enhanced heat transfer structure 4 are determined according to the distribution law of the heat source 8, the filling rate of the reinforced material, and the number of graded gradients. In this embodiment, the first-stage enhanced heat transfer structure is determined to be on the thermal diffusion bottom plate 7 by 6mm× The spacing of 6mm is evenly distributed, the cross-sectional shape is square, and the size is 2mm×2mm;

[0035] Each level of enhanced heat transfer structure can choose the fractal method according to the shape and size of the first-level enhanced heat transfer structure and the number of classifications. In this embodiment, since the cross-sectional sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com