Plant cultivation device based on nonwoven cloth cultivation technology

A planting technology and planting device technology, applied in the field of plant planting devices, can solve problems such as large engineering volume, increased roof weight, and difficulty in popularization, and achieve the effects of fast planting speed, low planting cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

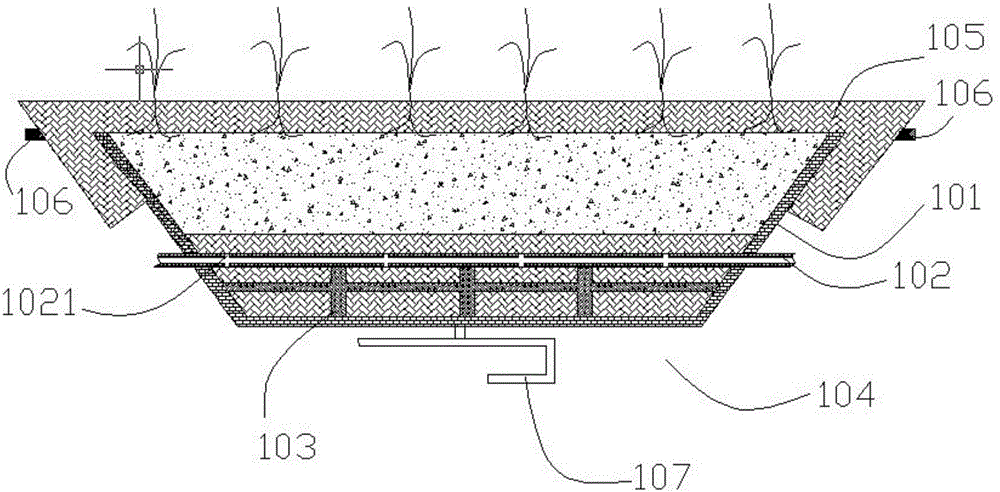

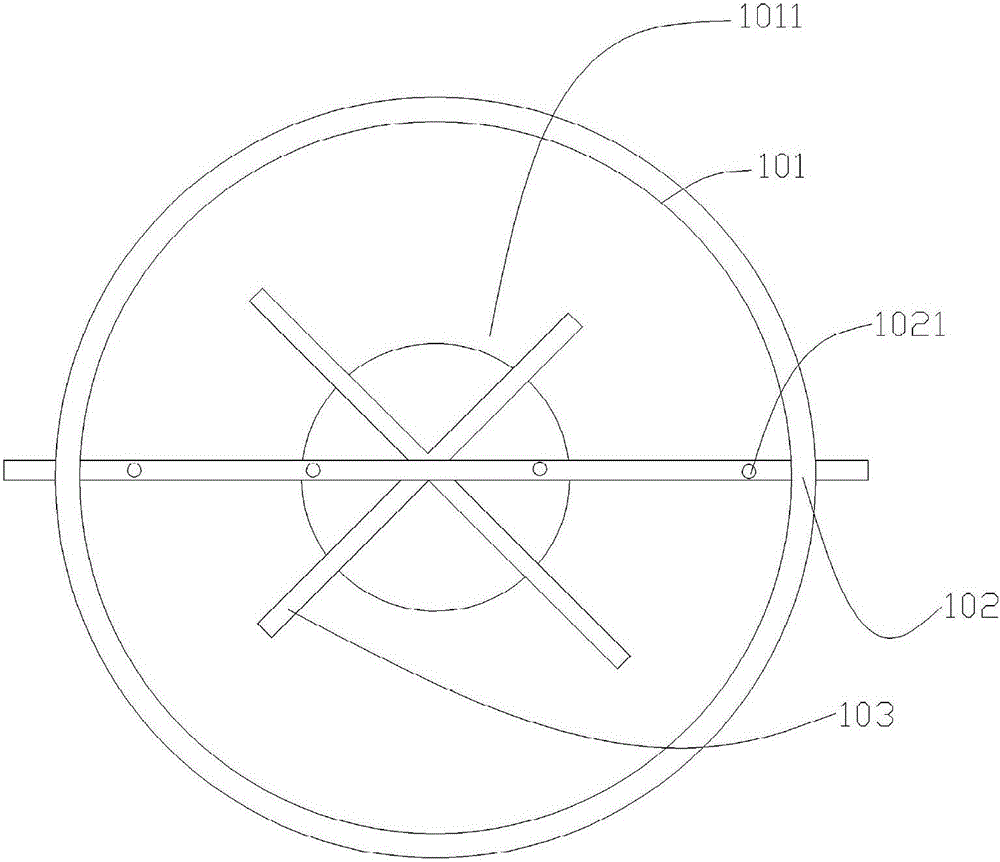

[0029] Such as figure 1 with figure 2 As shown, the plant planting device based on the non-woven fabric planting technology of the present invention includes a tray 101, a water application pipe 102, a support 103, a water distribution part 104, a base 105, a tightening part 106 and a positioning part 107, wherein,

[0030] Tray 101 is used for storing nutritious soil and plants, and water storage, and the center of tray 101 is sunken downwards and is formed with accommodating portion 1011, and the outer contour of accommodating portion 1011 is a conical frustum, and its top (opening) is a large end. The outer contour can be a cylinder, a truncated cone, a cuboid or other polygons, and the shape of the tray 101 can be selected according to the environment in which the plants are placed.

[0031] The water application pipe 102 is used to regularly water the plants. The water application pipe 102 is installed in the accommodation portion 1011 of the tray 101. The two ends of t...

Embodiment 2

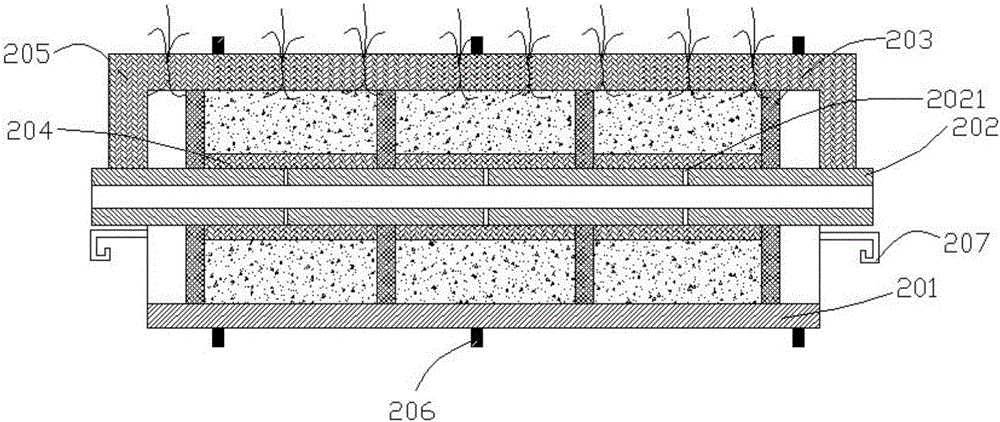

[0049] Such as Figure 3-5 As shown, the plant planting device based on the non-woven fabric planting technology includes a bracket 201, a water application pipe 202, several support members 203, a water diversion member 204, a base 205, a tightening member 206 and a positioning member 207, wherein,

[0050] Support 201 is used for storing nutritious soil and plants, and water storage, and support 201 is elongated shape, and support 201 is provided with groove 2011 along its length direction, and the external profile of support 201 can be cylinder, cuboid or other polygon, The shape of the support 201 can be selected according to the environment in which the plants are placed.

[0051] The water application pipe 202 is used to regularly water the plants. The water application pipe 202 is installed in the groove 2011 of the support 201. The two ends of the water application pipe 202 extend outwards from the support 201 respectively. The water application pipes 202 correspond to...

Embodiment 3

[0068] Such as Figure 6-7 As shown, the plant planting device based on non-woven fabric planting technology includes a filter screen 301, a water application pipe 302, several support members 303, a water diversion member 304, a base 305, a tightening member 306 and a positioning member 307, wherein,

[0069] The filter screen 301 is used to store nutritious soil and plants. The filter screen 301 is bent into a cylindrical shape. The filter screen 301 is made of elastic material. The filter screen 301 is made of plastic mesh or steel wire mesh, which can be changed by squeezing the filter screen 301 Its shape to achieve different landscaping effects.

[0070] The water application pipe 302 is used to regularly water the plants. The water application pipe 302 is installed in the cylinder formed by the filter screen 301. The two ends of the water application pipe 302 respectively extend outwards from the filter screen 301. The outer wall of the water application pipe 302 corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com