Method for planting plants on tin roof based on non-woven fabric

A planting method and non-woven technology, applied in the fields of botanical equipment and methods, plant cultivation, roofing, etc., can solve the problems of iron sheet collapse, loud noise, affecting comfort, etc., to ensure water supply, low planting cost, and operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

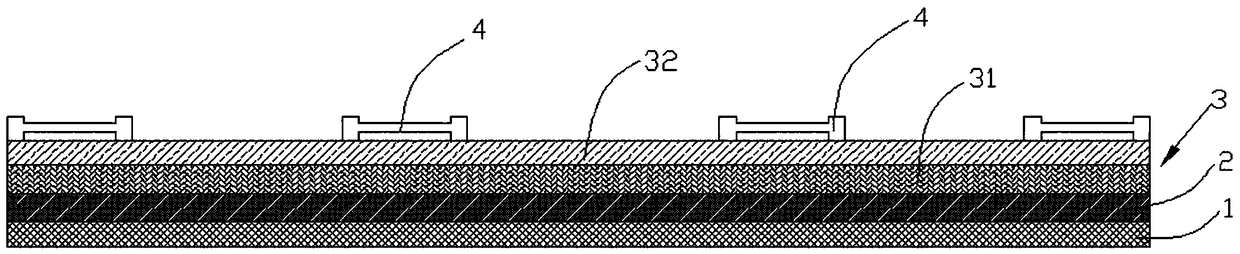

[0035] Such as figure 1 As shown, Embodiment 1: For flat iron roofs or iron roofs with inconspicuous convexities

[0036] 1. Lay a layer of waterproof layer 2 on the upper surface of the iron roof 1

[0037] The waterproof layer 2 completely covers the upper surface of the iron roof 1. The waterproof layer 2 is made of waterproof material. The waterproof layer 2 is used for waterproofing and prevents rainwater from entering the room from the gap of the iron roof 1; To achieve the effect of noise reduction and heat insulation, due to the buffering effect of the waterproof layer 2, the raindrops will not directly fall on the iron roof 1, so as to avoid the direct impact between the raindrops and the iron roof 1 to generate loud noise, the waterproof layer 2 The area of the waterproof layer 2 is equivalent to the area of the iron roof 1, and the thickness of the waterproof layer 2 is generally within the range of 0.2-5 cm. The thicker the waterproof layer 2, the better the n...

Embodiment 2

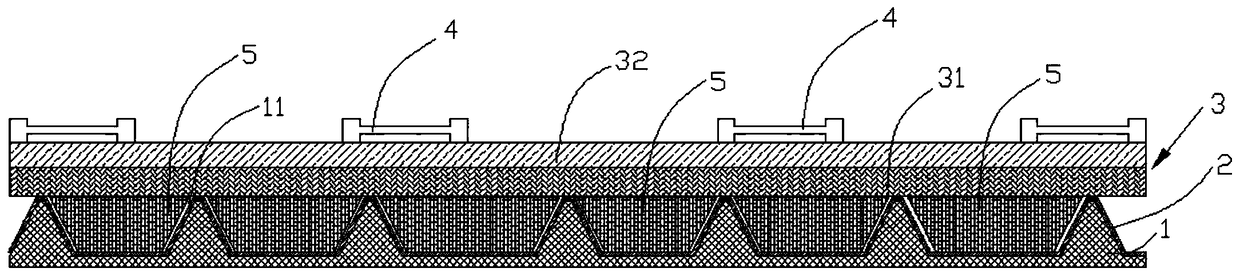

[0044] Such as figure 2 As shown, Embodiment 2: for iron roofs with obvious convex and concave

[0045] 1. Lay a layer of waterproof layer 2 on the upper surface of the iron roof 1

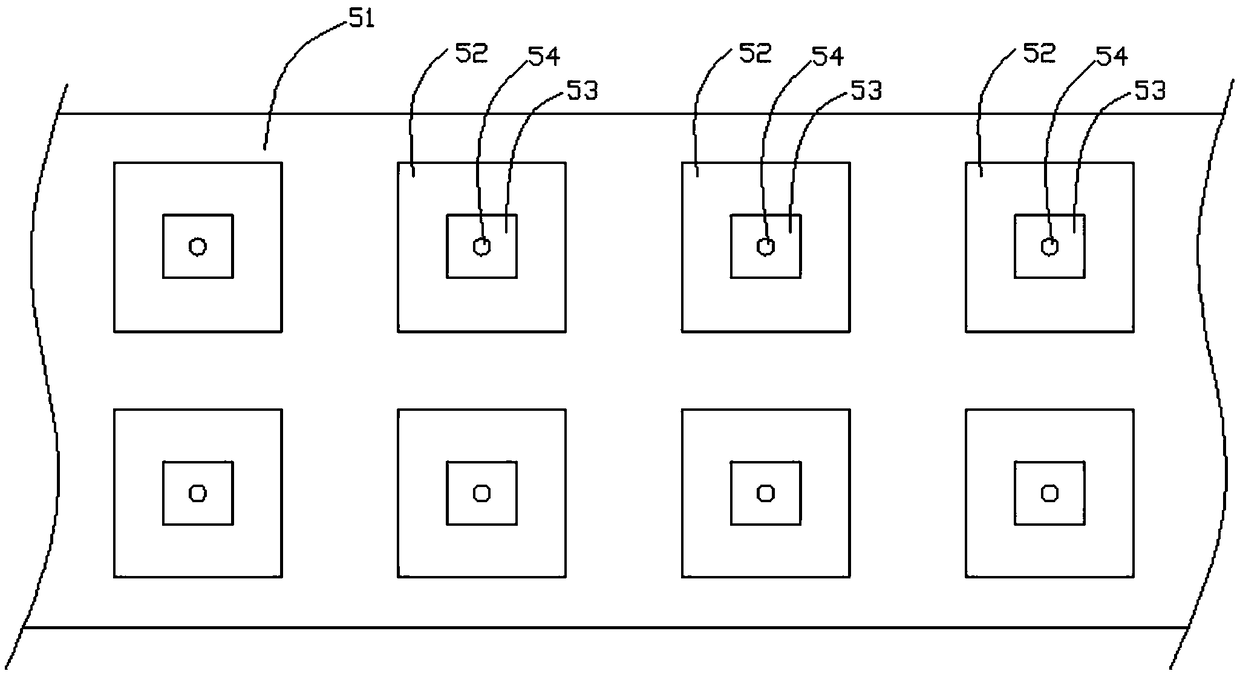

[0046] 2. Fill the water reservoir 5 in the groove 11 of the tin roof 1

[0047] The water storage device 5 realizes the water storage function on the one hand, and is used for long-term water supply to the planted plants, and on the other hand, realizes the filling function, and is used to ensure that the upper surface of the iron roof 1 is in a flat state, so as to facilitate the subsequent fixing of the non-woven fabric 3 . The shape of the water reservoir 5 is adapted to the shape of the groove 11 of the iron roof 1 (the height of the water reservoir 5 is consistent with the depth of the groove 11), and the water reservoir 5 is placed behind the groove 11 of the iron roof 1 to store water The upper surface of device 5 is flush with the convex surface (highest point) of tin roof 1.

[0048]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com