Technology based on building roof leakage prevention

A leak-proof and craftsmanship technology, applied in building roofs, buildings, roof decoration, etc., can solve the problems of human health impact, poor adhesion, strong smell, etc., and achieve the effect of reducing the number of manual watering and prolonging the waterproof life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

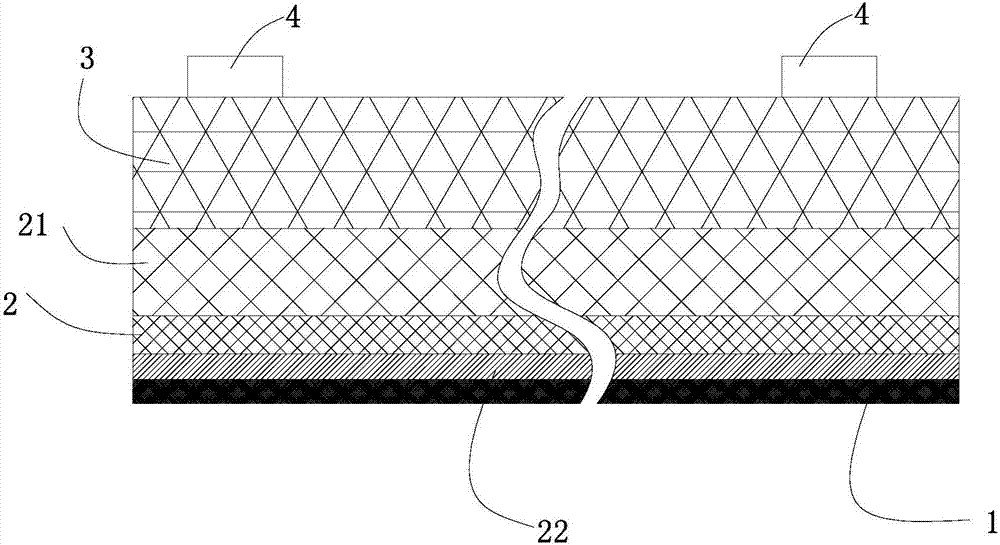

[0027] The present invention will be further elaborated below in conjunction with accompanying drawing, wherein, the direction of the present invention is with figure 1 as standard.

[0028] The invention discloses a process for preventing leakage of a building roof, which is realized by the following steps;

[0029] 1. Lay a layer of cloth membrane 2 on the upper surface of the roof 1

[0030] The fabric membrane 2 completely covers the upper surface of the roof 1, and the fabric membrane 2 is used for waterproofing to prevent rainwater from entering the room from the gaps in the roof 1. In addition, the fabric membrane 2 can also play a role in noise reduction and heat insulation. The cushioning effect of the membrane 2 prevents the raindrops from directly falling on the roof 1, avoiding the direct collision between the raindrops and the roof 1 and causing loud noise. The area of the fabric membrane 2 is equivalent to the area of the roof 1, and the The thickness is ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com