Preparation method of low-salt bone-removed instant ham using Landrace pig leg as raw material

A technology of Landrace pigs and raw materials, applied in food drying, food science, etc., can solve the problems of high tendon and fascia content, easy corruption, slow dehydration speed, etc., to achieve accelerated dissolution and interaction, uniform distribution and loss, The effect of reducing the use of salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

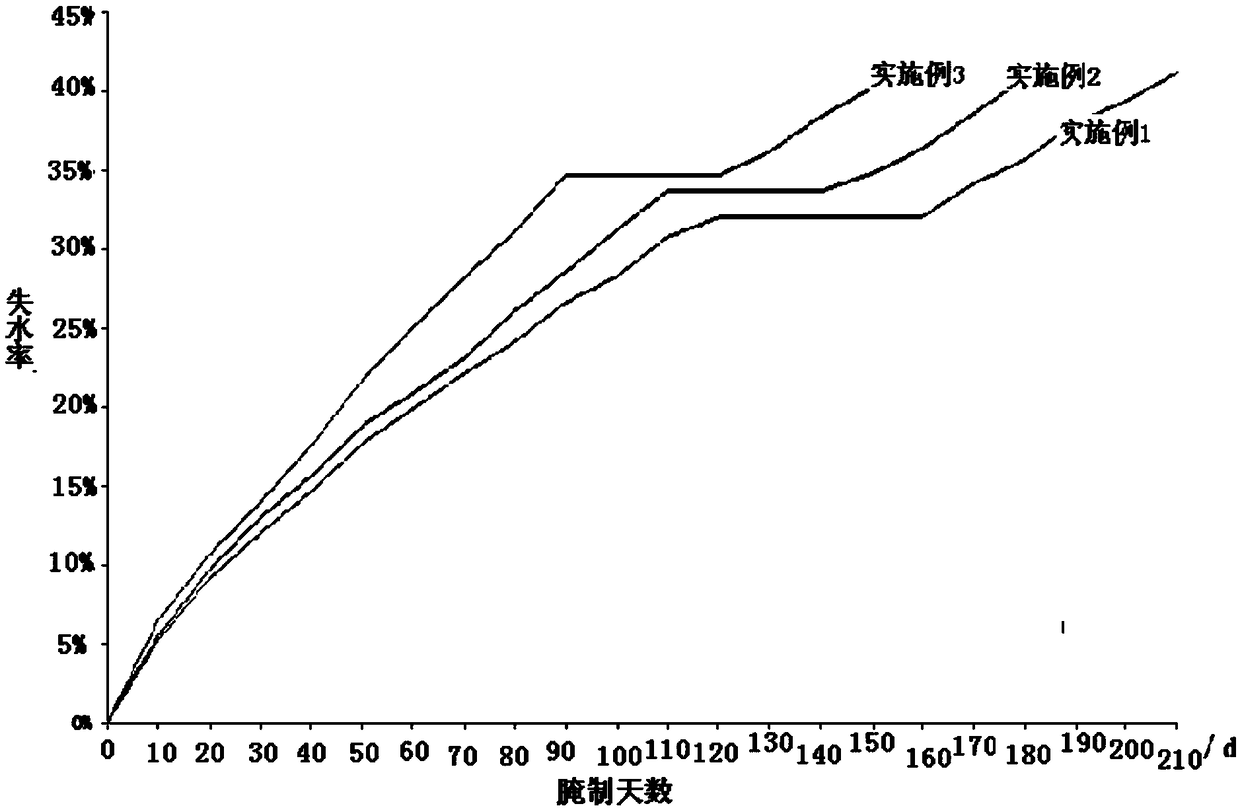

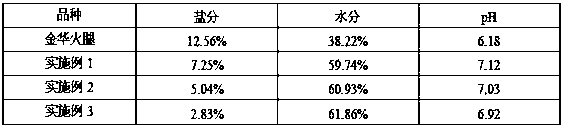

Embodiment 1

[0027] The longest cycle group: a preparation method of low-salt deboned ready-to-eat ham using Landrace pig legs as raw materials, using 29 Landrace pig hind legs weighing 15-18kg as raw materials, including material selection, bone removal, shaping, rolling and kneading Salt, rolling and tenderizing, mantle pickling, dehydration, standing still to seal and soften, promote enzymatic hydrolysis, mantle air-drying, mature, the total time is about 7 months to prepare. Specifically include the following steps:

[0028] (1) Material selection, deboning and shaping

[0029] Choose the hind leg of Landrace pig as the raw material, cut the meat from the middle, and manually remove the hip bone, femur, fibula and tibia; recombine the cut meat, cut off the minced meat left by the bone removal, and cut the meat surface Flattened, convex in the middle, about 2cm higher than the edge, the height gradually decreases from the middle to the edge, and the overall shape is oval;

[0030] (2)...

Embodiment 2

[0043] Faster mature group: a preparation method of low-salt deboned ready-to-eat ham using Landrace pig leg as raw material, using 40 Landrace pig hind legs weighing 12-15kg as raw material, including material selection, bone removal, shaping, rolling and salting , rolled and tenderized, the mantle was marinated, dehydrated, left to stand and sealed to soften, promote enzymolysis, the mantle was air-dried, matured, and it took about 6 months to prepare.

[0044] With above-mentioned embodiment 1, its difference is:

[0045] Step (2) is changed to table salt: 35g / kg; substitute salt (50% potassium chloride-50% potassium citrate) 15g / kg; 40 strips of boneless raw meat have a total weight of 556kg, weigh 19.46kg of table salt, and substitute salt 8.34kg (potassium chloride 4.17kg, potassium citrate 4.17kg), sodium nitrite 83.4g, potassium nitrate 83.4g, sodium ascorbate 278g, glucose 556g, nicotinamide 389.2g;

[0046] In step (3), change the total amount of transglutaminase to...

Embodiment 3

[0052] Rapid maturation group: a preparation method of low-salt deboned ready-to-eat ham using Landrace pork legs as raw materials, using 21 hind legs of Landrace pigs weighing 9-12kg as raw materials, including material selection, bone removal, shaping, rolling and salting , rolling and tenderizing, the mantle is marinated, dehydrated, left standing to seal and soften, promote enzymolysis, mantle is air-dried, and matured. It takes about 5 months to prepare.

[0053] With above-mentioned embodiment 1, its difference is:

[0054] Step (2) is changed to table salt: 15g / kg; substitute salt (50% potassium chloride-50% potassium citrate) 20g / kg; 31 strips of boneless raw meat have a total weight of 334.8kg, weigh 5.022kg of table salt, and substitute Salt 6.696kg (potassium chloride 3.348kg, potassium citrate 3.348kg), sodium nitrite 50.22g, potassium nitrate 50.22g, sodium ascorbate 167.4g, glucose 334.8g, nicotinamide 234.36g;

[0055] Step (3) was changed to 669.6g of transglu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com