Ground-road combined comprehensive tunnel for underground pipeline and trolley bus

A technology for trolleybuses and underground pipelines, applied in the fields of municipal and traffic engineering, can solve the problems of inability to lay pipelines in underground passages and the reduction of the scale of ventilation facilities, and achieve the effects of saving ventilation operation costs, improving carrying capacity, and improving passing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

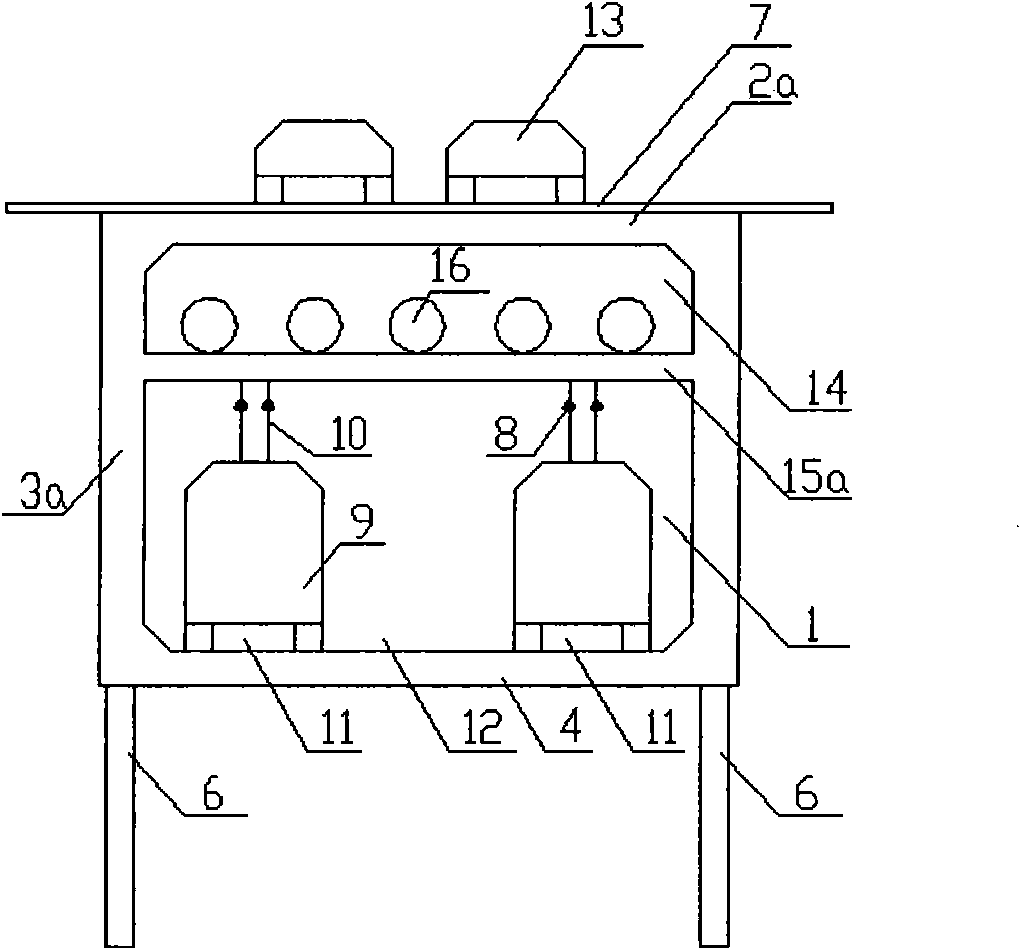

[0050] see figure 1 , using the shallow underground space of the ground road 7, combined with the ground road 7 to set up an underground comprehensive passage. Porous (not shown on the figure), the underground comprehensive passage lower layer 1 is used as the passage of trolley bus 9, the underground comprehensive passage upper layer 14 is used as the passage of pipeline 16, and the roof 2a top of the box culvert structure is laid with a surface layer as the ground road 7, and the underground comprehensive The side wall 3a or the top plate 2a of the channel upper layer 14 is provided with a special installation and inspection port (not shown in the figure), and the bottom of the middle plate and support 15a is provided with an overhead catenary 8, which is connected to the trolleybus current collector 10 to the trolleybus. 9 power supply, the ventilation facility (not shown on the figure) that only needs to satisfy the breathing needs of drivers and passengers on the lower fl...

Embodiment 2

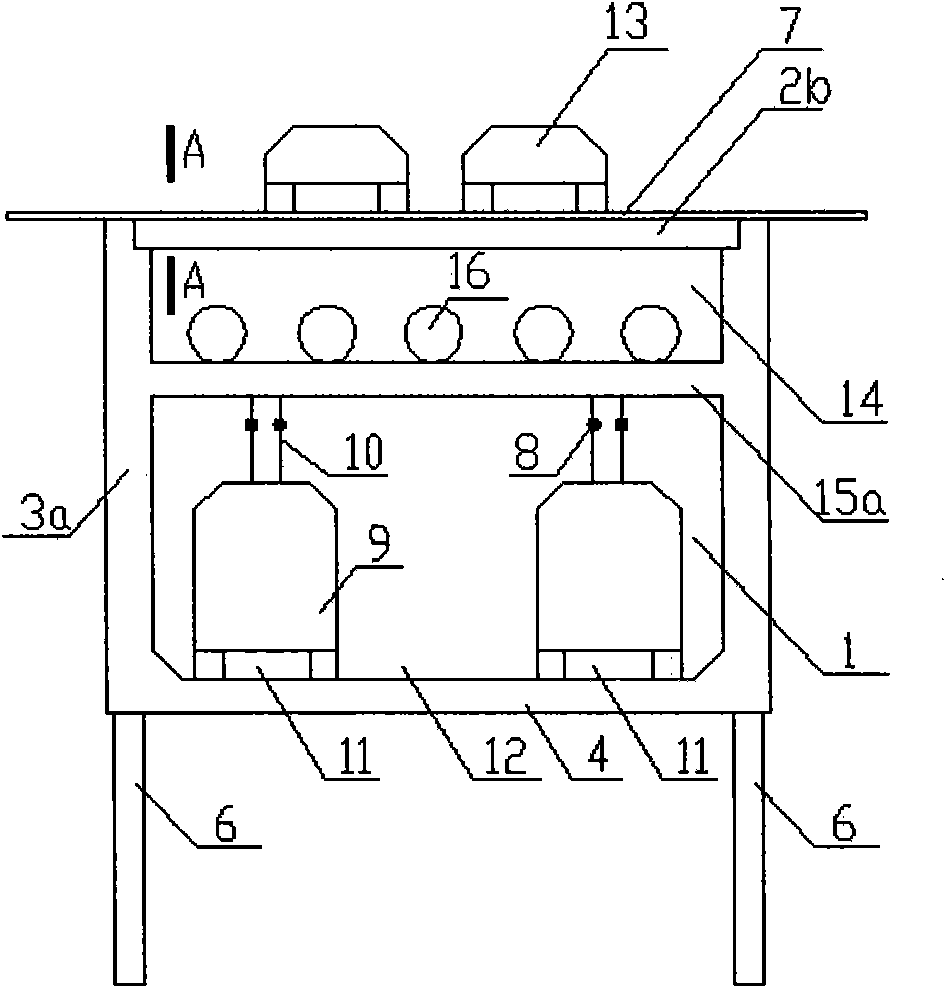

[0052] see figure 2 , The underground comprehensive passage adopts a combined structure of box culvert and prestressed hollow panel 2b, which is composed of prestressed hollow panel 2b, side wall 3a, middle plate and support 15a and bottom plate 4. The prestressed hollow panel 2b adopts a horizontal arrangement, that is, the longitudinal direction of the cavity 17 of the prestressed hollow panel 2b is perpendicular to the longitudinal direction of the underground comprehensive passage. The side wall 3a, the middle plate and support 15a, and the bottom plate 4 adopt a reinforced concrete structure or a prestressed reinforced concrete structure, and the prestressed hollow panel adopts a pretensioned prestressed reinforced concrete structure or a posttensioned prestressed reinforced concrete structure. All the other are the same as embodiment one.

Embodiment 3

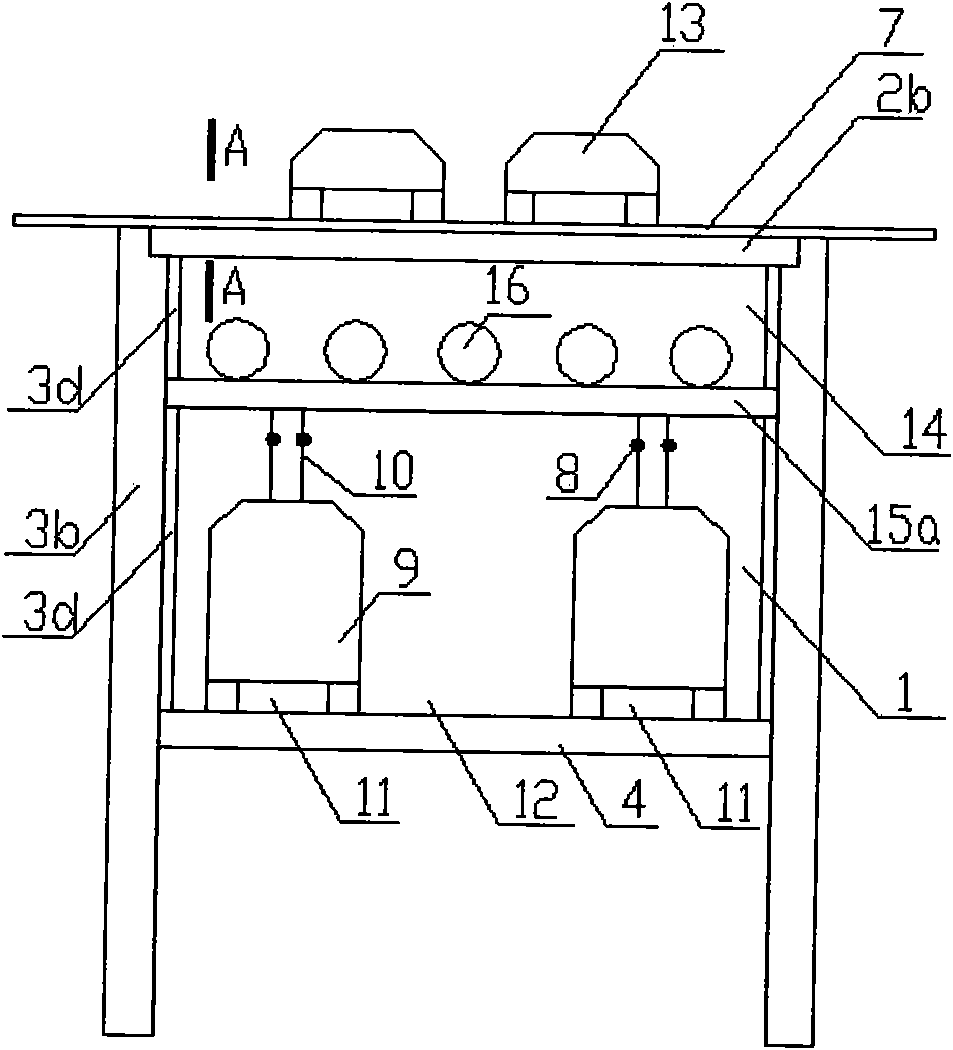

[0054] see image 3 , using the shallow underground space of the ground road 7, combined with the ground road 7 to set up an underground comprehensive passage. Porous (not shown on the figure), the underground comprehensive passage lower layer 1 is used as the passage of the trolley bus 9, the underground comprehensive passage upper layer 14 is used as the passage of the pipeline 16, and the surface layer is laid on the top of the prestressed hollow panel 2b as the ground road 7, and the underground comprehensive passage The side wall 3b or the roof 2b of the upper floor 14 is provided with a special installation and inspection port (not shown on the figure), and the bottom of the middle plate and support 15a is provided with an overhead catenary 8, which is connected to the trolleybus 9 by contact with the trolleybus current collector 10. For power supply, the ventilation facility (not shown on the figure) that only needs to satisfy the breathing needs of the drivers and pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com