Monocrystalline silicon system flocking additive for crystalline silicon solar battery

A technology of solar cells and additives, applied in crystal growth, post-processing details, post-processing, etc., can solve problems such as high cost and unbalanced ratio of liquid medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Texturing additive ratio is:

[0027] Glycerin polyoxypropylene ether is 1%, fatty amine polyoxyethylene ether is 0.05%, methyl pyruvate is 5%, vitamin C is 0.1%, oxalic acid is 3%, lactic acid is 5%, NaOH is 2%, and the rest is Deionized water.

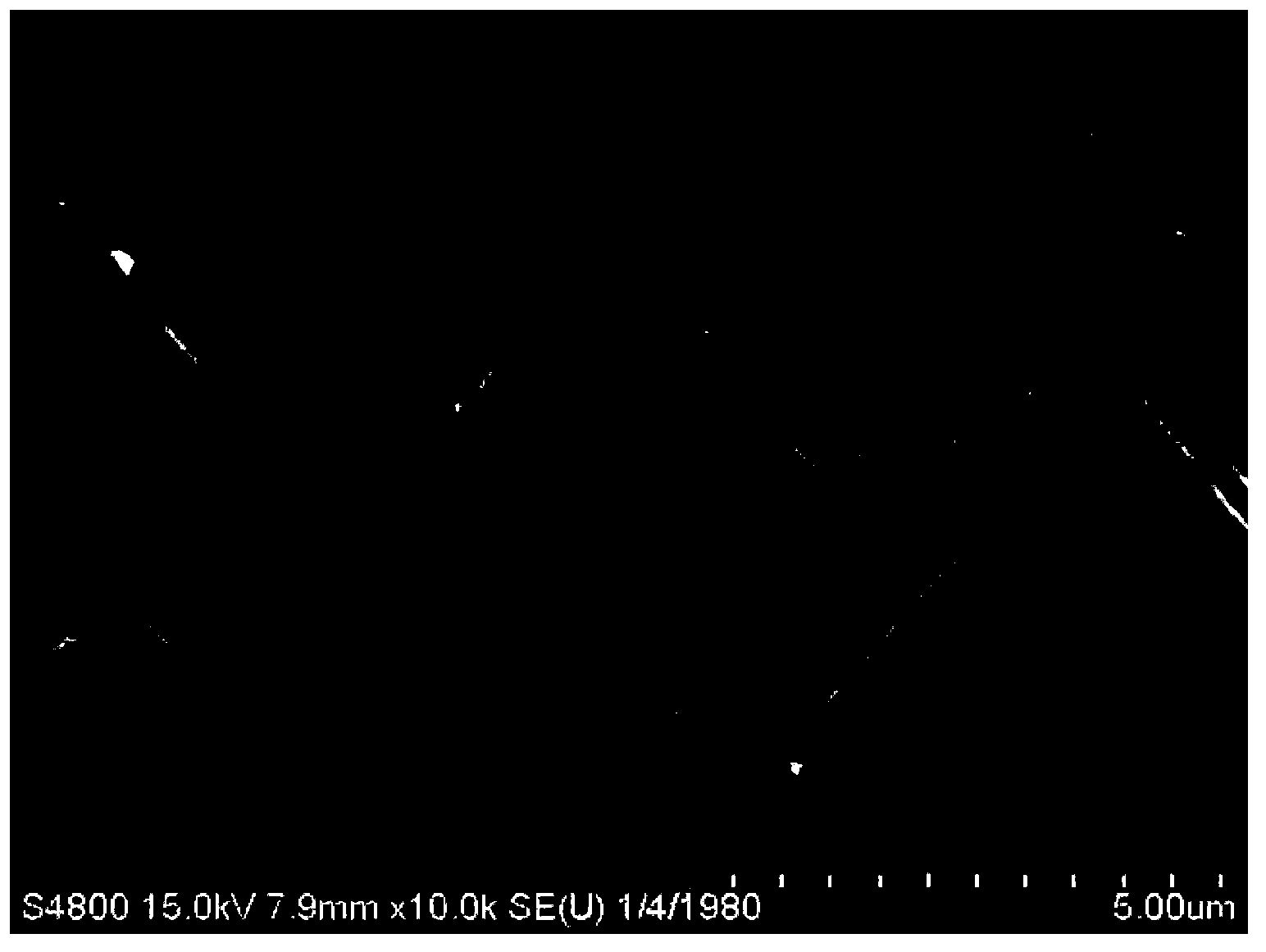

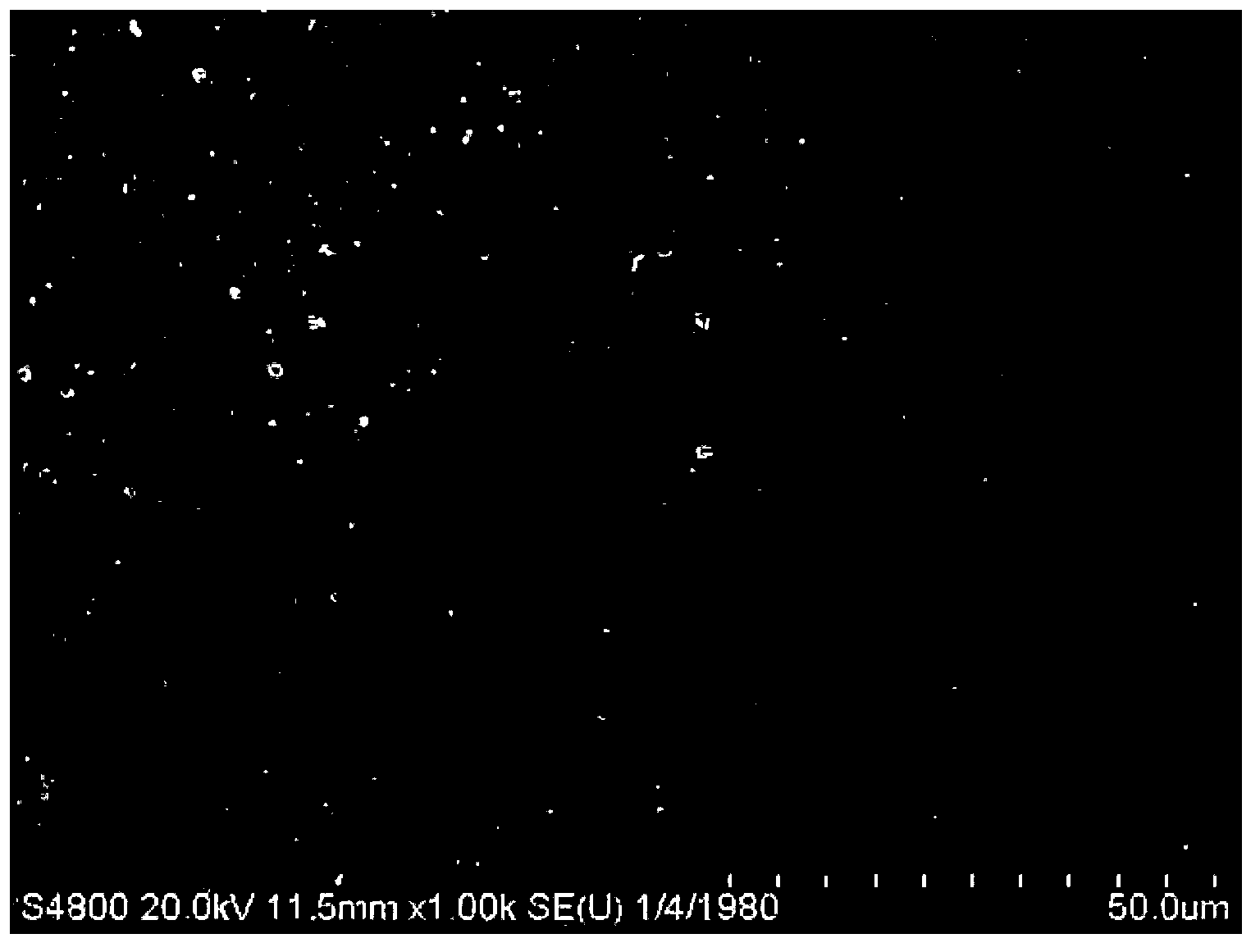

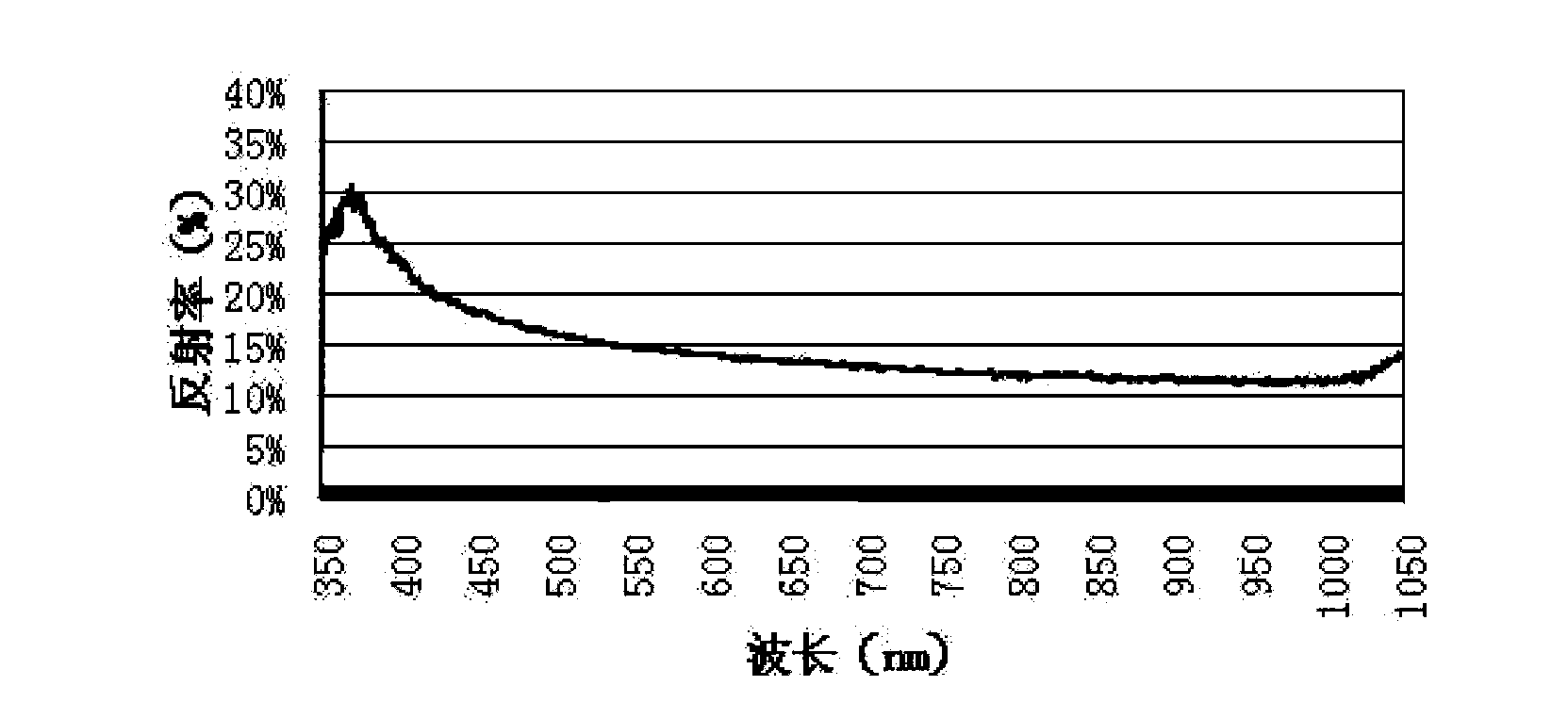

[0028] Add 1000ml of texturing additive according to the above formula into a 150L single crystal texturing tank. The NaOH content in the texturing tank has been configured to be 1.8%. The temperature of the texturing tank is controlled at 80°C. The sheet is soaked into the texture-making tank for reaction, and the texture-making time is controlled at 900 seconds to 1200 seconds, and the average size of the obtained texture pyramid is about 3-4um. Each subsequent batch (the number of silicon wafers in a batch is 200-400 pieces) only needs to add 200-300 grams of NaOH and 20ml of additives.

[0029] After the above method continues to produce 40-60 batches, due to the reflection of the product Na in the texturing tank 2 SiO ...

Embodiment 2

[0031] Texturing additive ratio is:

[0032] Glycerin polyoxypropylene ether is 1.5%, fatty amine polyoxyethylene ether is 0.03%, methyl pyruvate is 2.5%, vitamin C is 1.5%, oxalic acid is 1.5%, lactic acid is 2.5%, and NaOH is 1%. ionized water.

[0033] Add 1000ml of the texturing additive prepared according to the above formula into a 100L single crystal texturing tank. The NaOH content in the texturing tank has been configured to be 1.8%. The temperature of the texturing tank is controlled at 80°C. The sheet is soaked in the texturing tank for reaction, and the texturing time is controlled at 1200 seconds to 1500 seconds, and the average size of the obtained texture pyramid is about 2um. Each subsequent batch (the number of silicon wafers in a batch is 300-400 pieces) needs to add 200-300 grams of NaOH and 20ml of additives;

[0034] After the above method continues to produce 40-60 batches, due to the reaction product Na in the texturing tank 2 SiO 3 If the content is...

Embodiment 3

[0036] Texturing additive ratio is:

[0037] Glycerin polyoxypropylene ether is 2%, fatty amine polyoxyethylene ether is 0.01%, methyl pyruvate is 0.5%, vitamin C is 5%, oxalic acid is 0.1%, lactic acid is 0.1%, NaOH is 0.1%, and the rest is Deionized water.

[0038] Add 1000ml of the texturing additive prepared according to the above formula into a 100L single crystal texturing tank. The NaOH content in the texturing tank has been configured to be 1.8%. The temperature of the texturing tank is controlled at 80°C. The sheet is soaked in the texturing tank for reaction, and the texturing time is controlled at 1200 seconds to 1500 seconds, and the average size of the obtained texture pyramid is about 2um. Each subsequent batch (the number of silicon wafers in a batch is 300-400 pieces) needs to add 200-300 grams of NaOH and 20ml of additives;

[0039] After the above method continues to produce 40-60 batches, due to the reaction product Na in the texturing tank 2 SiO 3 If th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com