High-quality composting pretreatment method and device for urban kitchen waste

A food waste and pretreatment technology, applied in the direction of organic fertilizer, climate change adaptation, etc., can solve the problems of difficult to guarantee the quality of composting, poor physical properties of food waste, etc., and achieve operability, resistance to corruption and odor, The effect of inhibiting the growth of spoilage bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

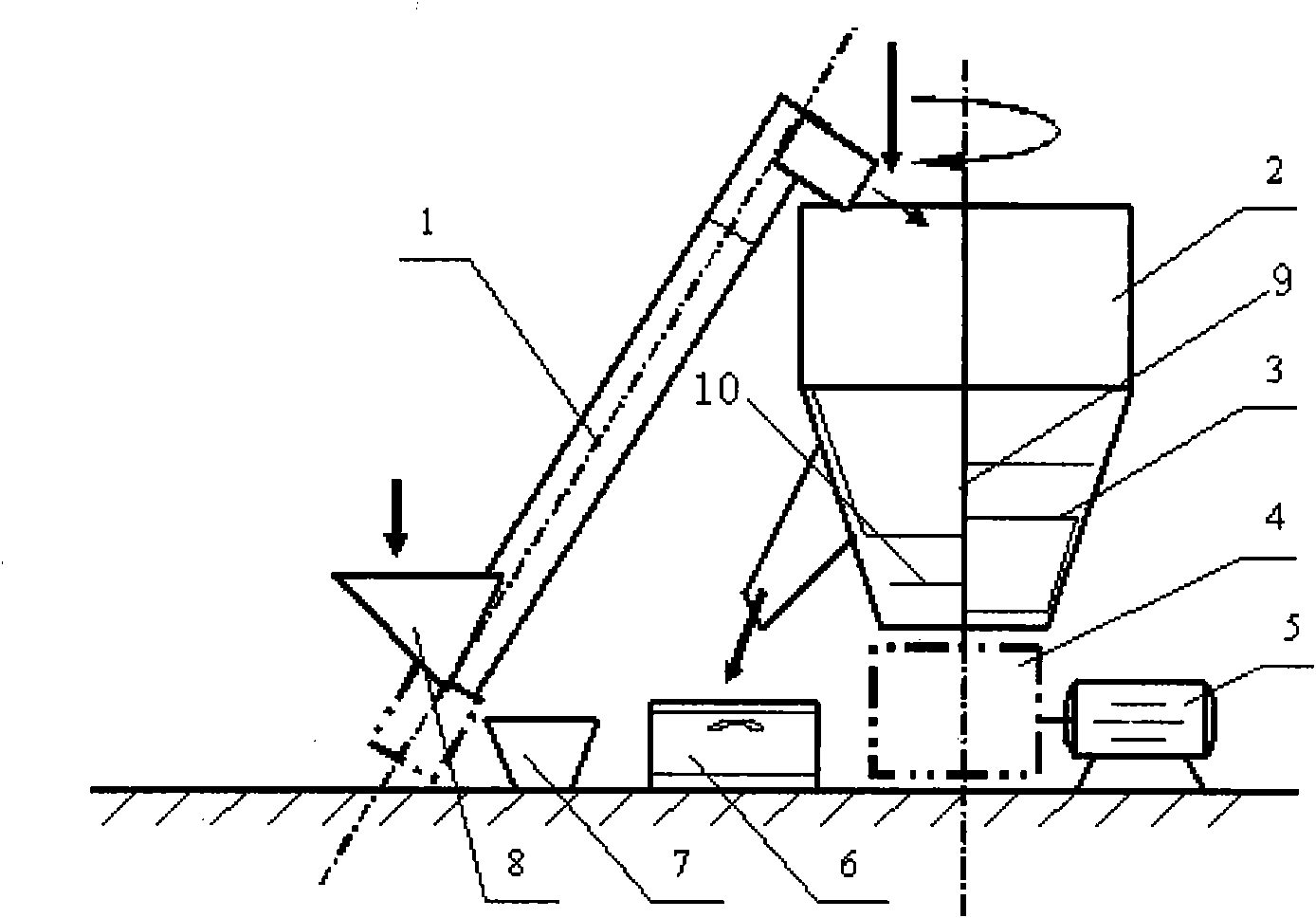

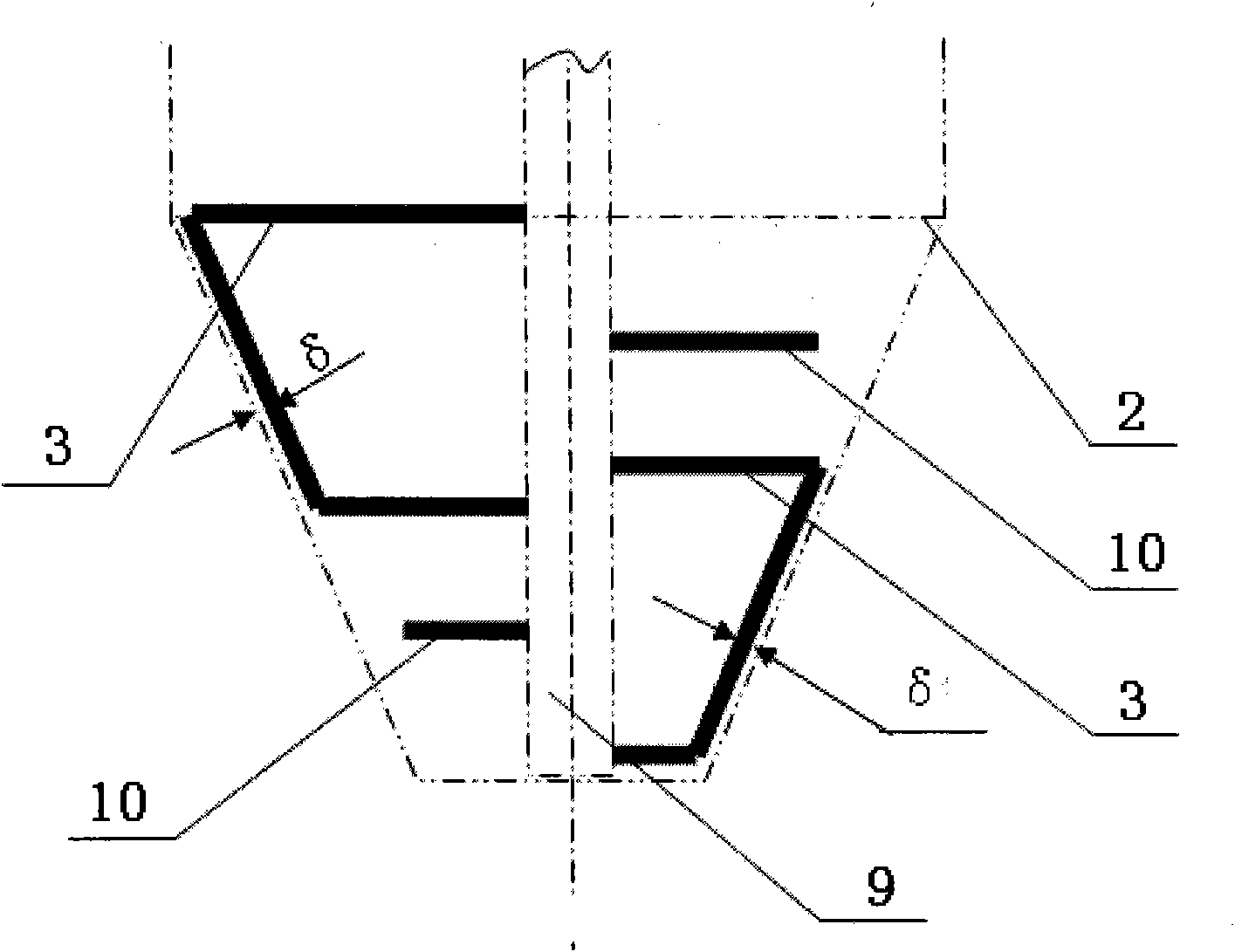

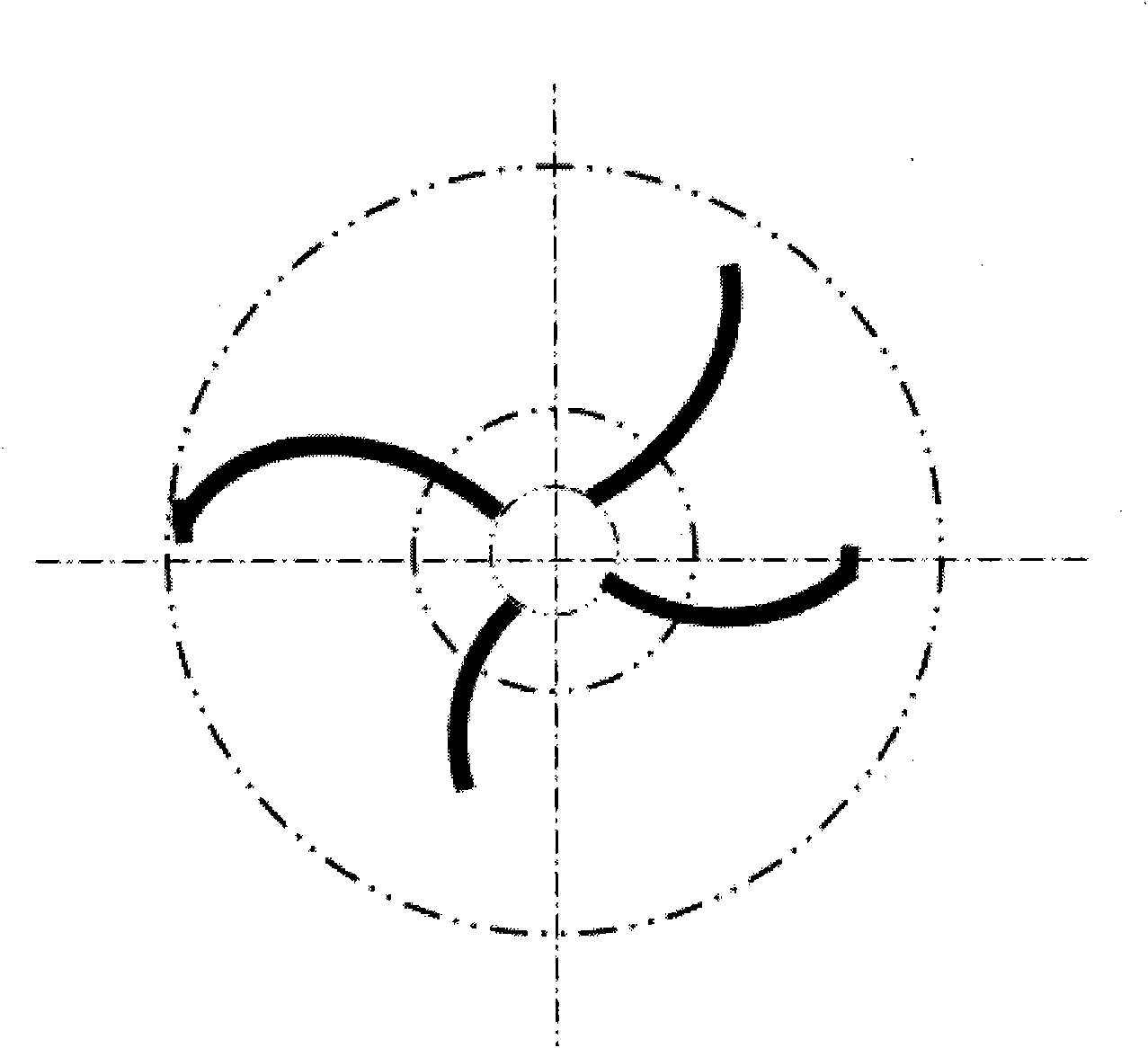

Method used

Image

Examples

Embodiment 1

[0024] Example 1: 90kg of food waste in a canteen of a certain enterprise, with a moisture content of about 85%, squeezed the food waste with a screw press to make the water content of the food waste reach 68%, and combined the squeezed food waste with a paper cutter 6kg of office waste paper discharged, 12kg of composted return material, added to composting pretreatment equipment for 60 minutes, and finally obtained a homogeneous composting pretreatment 59.2kg, composting pretreatment moisture 54.2%, total carbon 38.21% , total nitrogen 1.05%, C / N=36.39%.

Embodiment 2

[0025] Example 2: 120kg of food waste in a canteen of a certain enterprise, with a moisture content of about 88%, squeezed the food waste with a screw press to make the water content of the food waste reach 70.1%, and combined the squeezed food waste with a paper cutter 8kg of office waste paper discharged, 18kg of composted return material, added to composting pretreatment equipment for 60 minutes, and finally 73kg of homogeneous composting pretreated material was obtained. The composting pretreated material contained 53.6% moisture and 41.25% total carbon. Total nitrogen 1.12%, C / N=36.83%.

Embodiment 3

[0026] Embodiment 3: 102kg of kitchen waste in a certain hotel restaurant, about 86% of moisture, the kitchen waste is squeezed with a screw press to make the moisture of the kitchen waste reach 71%, and the squeezed kitchen waste and sawdust 7kg, 14kg of composting returned material was added to the composting pretreatment equipment for 60 minutes, and finally 73.6kg of homogeneous composting pretreatment was obtained. The composting pretreatment contained 57.7% moisture, 42.10% total carbon, 1.29% total nitrogen, / N=32.64%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com