Preparation method and application for fructus gardeniae extract for tobacco

An extract, the technology of gardenia smoke, applied in the field of preparation of gardenia smoke extract, can solve the problems of reducing the pH value of smoke, achieve the effects of improving aroma quality, high product yield, and reducing irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

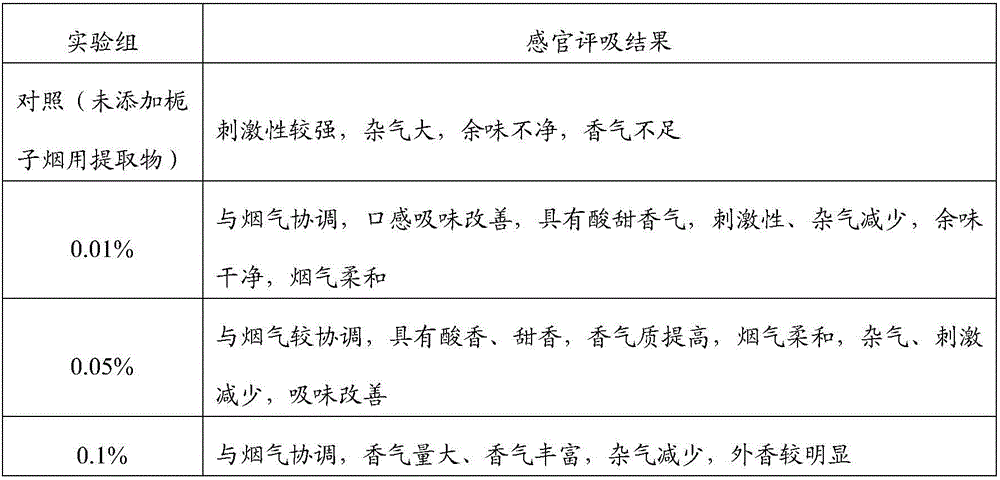

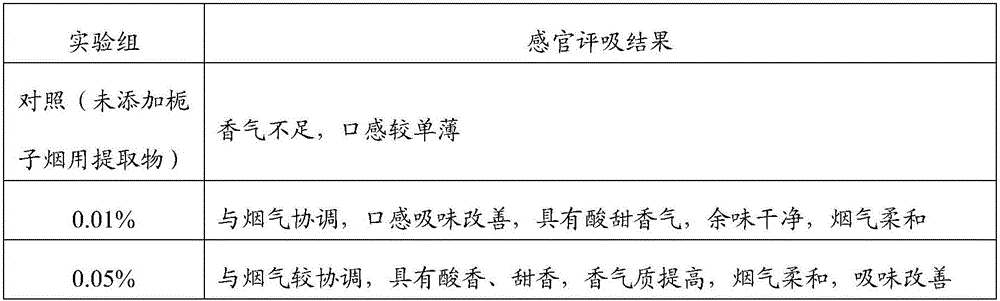

Examples

Embodiment 1

[0021] A preparation method of the extract of Gardenia jasminoides:

[0022] 1) Put the gardenia fruit into an extraction tank after being crushed, add water with a mass ratio of 1:20, and add lactic acid bacteria and compound enzymes in an amount of 0.3% of the gardenia fruit mass, stir evenly, and dissolve at 45°C and pH Under natural conditions, ferment for 3 hours to obtain a gardenia fermented liquid;

[0023] Described lactic acid bacteria and compound enzyme are: account for 0.3% of gardenia fruit quality altogether, wherein lactic acid bacteria freeze-dried bacteria powder (food grade) accounts for 0.15%, β-glucosidase (food grade, enzyme activity is 1000u / g) accounts for 0.075% %, neutral protease (food grade, enzyme activity 50,000 u / g) accounts for 0.075%;

[0024] 2) Alcohol precipitation and purification: add 15% ethanol (95%, food grade) of water volume to the gardenia fruit fermentation broth, extract 3 times at low temperature and pressure, filter with suction...

Embodiment 2

[0029] A preparation method of an extract of gardenia jasminoides for tobacco use, comprising the following steps:

[0030] 1) Put the gardenia fruit into an extraction tank after being crushed, add water with a mass ratio of 1:30, and add lactic acid bacteria and compound enzymes according to 0.18% of the gardenia fruit mass, stir evenly, and put it under natural conditions of 50°C and pH , fermented for 4h to obtain gardenia fermented liquid;

[0031] Described lactic acid bacteria and compound enzyme are: account for 0.18% of gardenia fruit quality altogether, wherein lactic acid bacteria freeze-dried bacterial powder (food grade) accounts for 0.1%, β-glucosidase (food grade, enzyme activity is 10,000 u / g) Accounted for 0.05%, neutral protease (food grade, enzyme activity 120,000 u / g) accounted for 0.03%;

[0032] 2) Alcohol precipitation and purification: add 25% ethanol (food grade, 95%) of water volume to the gardenia fruit fermentation liquid, extract 3 times at low te...

Embodiment 3

[0037] A preparation method of an extract of gardenia jasminoides for tobacco use, comprising the following steps:

[0038] 1) Put the gardenia fruit into an extraction tank after being crushed, add water with a mass ratio of 1:40, and add lactic acid bacteria and compound enzymes according to 0.25% of the gardenia fruit mass, stir evenly, and store at 60°C and pH natural conditions , fermented for 6h to obtain gardenia fruit fermentation liquid;

[0039] Described lactic acid bacteria and compound enzyme are: account for 0.25% of gardenia fruit quality altogether, wherein lactic acid bacteria freeze-dried bacteria powder (food grade) accounts for 0.14%, β-glucosidase (food grade, enzyme activity is 9000u / g) accounts for 0.07% %, neutral protease (food grade, enzyme activity 200,000 u / g) accounts for 0.04%;

[0040] 2) Alcohol precipitation and purification: add 30% ethanol (food grade, 95%) of water volume to the gardenia fruit fermentation liquid, extract 3 times at low tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com