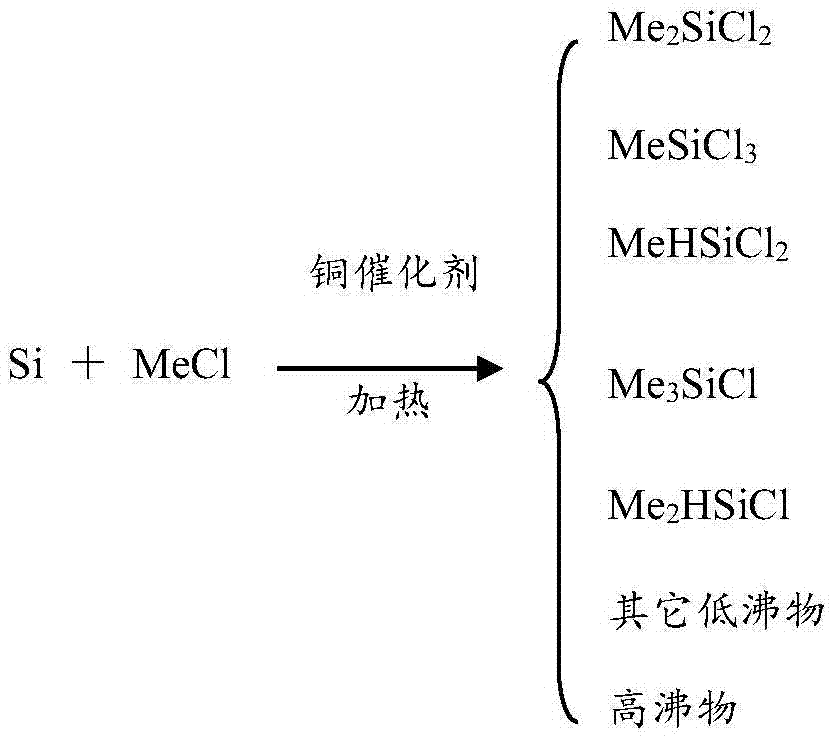

Preparation method of ZnO assistant-containing copper catalyst for synthesis of methylchlorosilane

A technology of methyl chlorosilane and copper catalyst, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., which can solve the problems of unfavorable ball milling and uniform dispersion of additive ZnO, Problems such as uneven particle density and difficult operation and control of ball milling can achieve the effects of good catalytic effect, high equipment utilization rate and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

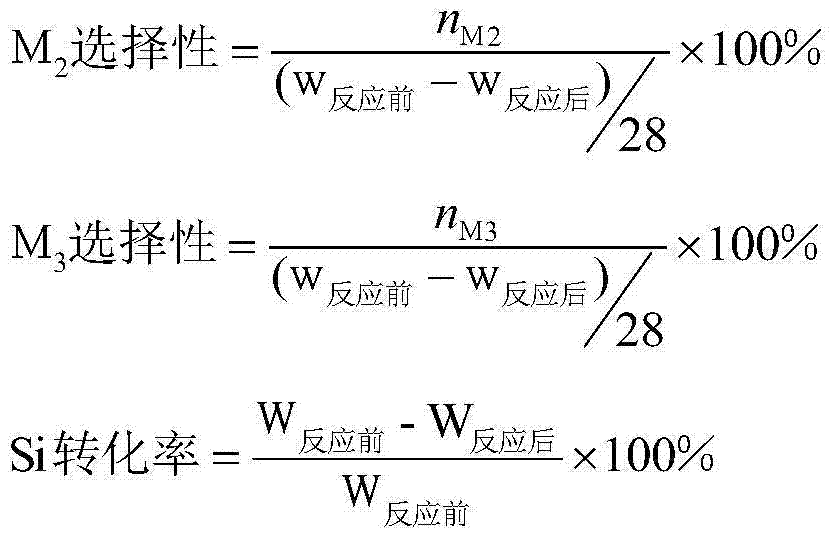

Embodiment 1

[0049] Add the sodium carbonate solution with a concentration of 1.5mol / L into the zinc chloride solution with a concentration of 8mol / L under stirring to obtain a white jelly, add 300g of atomized copper powder to the white jelly, and fully Stir to obtain a uniform mixture of white jelly and copper powder. After standing and aging for 4 hours to separate layers, wash and filter the sediment in the lower layer to obtain a uniform mixture of copper powder and basic zinc carbonate. The mixture was placed in a vacuum drying oven, dried in vacuum at 30°C for 6 hours, pulverized, put into a tube furnace, and air was introduced when the temperature was raised to 400°C. The molar ratio of the amount of air to the copper powder added was 15. After oxidizing for 5 hours, stop heating and aeration. The obtained mixture of partially oxidized copper powder and ZnO was subjected to wet ball milling, the mass ratio of ball milling beads to material was 20, the mass ratio of ball milling bea...

Embodiment 2

[0051] Add the sodium carbonate solution with a concentration of 3.5mol / L into the zinc nitrate solution with a concentration of 20mol / L under stirring to obtain a white jelly, add 300g of electrolytic copper powder to the white jelly, and fully stir, A homogeneous mixture of white jelly and copper powder was obtained, and after standing and aging for 8 hours to separate layers, the lower sediment was washed and filtered to obtain a homogeneous mixture of copper powder and basic zinc carbonate. The mixture was placed in a vacuum drying oven, dried under vacuum at 100°C for 5 hours, pulverized, put into a tube furnace, and air was introduced when the temperature was raised to 400°C. The molar ratio of the amount of air to the copper powder added was 15. After oxidizing for 5 hours, stop heating and aeration. The obtained mixture of partially oxidized copper powder and ZnO was subjected to dry ball milling, the mass ratio of ball milling beads to material was 2, and the ball mil...

Embodiment 3

[0053] Add the sodium carbonate solution with a concentration of 1.5mol / L into the zinc sulfate solution with a concentration of 10mol / L under stirring to obtain a white jelly. After standing and aging for 12 hours, add 300g of electrolytic copper powder, and fully Stir, wash and filter to obtain a uniform mixture of copper powder and basic zinc carbonate. The mixture was placed in a vacuum drying oven, dried under vacuum at 100°C for 1 hour, pulverized, put into a tube furnace, and air was introduced when the temperature was raised to 600°C. The molar ratio of the amount of air to the copper powder added was 8. After oxidizing for 2.5 hours, stop heating and ventilation. The obtained mixture of partially oxidized copper powder and ZnO was subjected to wet ball milling, the mass ratio of ball milling beads to material was 2, the mass ratio of ball milling beads to liquid dispersant was 1, and the ball milling time was 4 hours. After ball milling, the catalyst samples were obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com