Preparation method of CNT (carbon nano tube) reinforced aluminum composite

A carbon nanotube and aluminum-based technology, applied in the field of materials, can solve the problems of weakening the mechanical properties of composite materials, easy agglomeration and deactivation of catalysts, and large specific surface area of substrates, achieving good generalizability, short acidification treatment time, and solving problems the effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

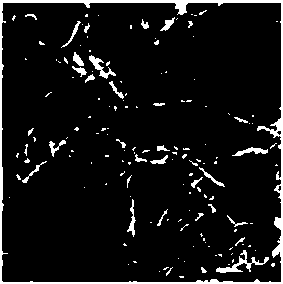

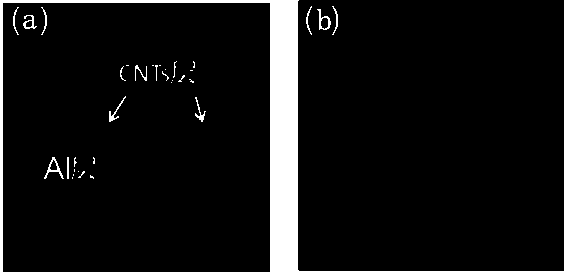

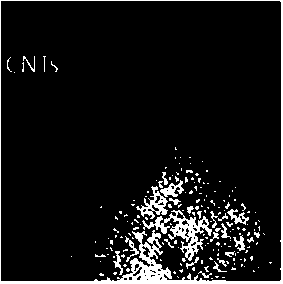

Image

Examples

Embodiment 1

[0030] 1) Mix concentrated nitric acid and concentrated sulfuric acid at a volume ratio of 1:3 to form a mixed acid solution, acidify 0.4g of carbon nanotubes in the mixed acid solution for 2 hours to remove amorphous carbon, then suction filter and dry to remove soluble impurities ;

[0031] 2) Mix ethanol and acetone in a volume ratio of 1:1.1 to form a mixed organic solution, dissolve the carbon nanotubes treated in step 1) in 500mL mixed organic solution, add 0.1g Al(NO 3 ) 3 , sonicated for 4 hours to obtain a uniform and stable CNTs plating solution;

[0032] 3) Cut the pure aluminum foil into a size of 40×40mm 2 The small square piece, wash the oil on the surface with acetone, and put it in acetone for preservation;

[0033] 4) The aluminum foil obtained in step 3) was used as the electroplating cathode, and the stainless steel sheet was used as the electroplating anode, and placed in the electrophoretic deposition mold. The distance between the two electrodes was co...

Embodiment 2

[0037] 1) Mix concentrated nitric acid and concentrated sulfuric acid at a volume ratio of 1:3 to form a mixed acid solution, acidify 0.4 g of carbon nanotubes in the mixed acid solution for 2 hours to remove amorphous carbon, then suction filter and dry to remove soluble impurities ;

[0038] 2) Mix organic solution with ethanol and acetone at a volume ratio of 1:1.1, dissolve the carbon nanotubes treated in step 1) in 500 mL mixed organic solution, add 0.1g Al(NO 3 ) 3 , sonicated for 4 hours to obtain a uniform and stable CNTs plating solution;

[0039] 3) Cut the pure aluminum foil into a size of 40×40mm 2 The small square piece, wash the oil on the surface with acetone, and put it in acetone for preservation;

[0040] 4) The aluminum foil obtained in step 3) was used as the electroplating cathode, and the stainless steel sheet was used as the electroplating anode, and placed in the electrophoretic deposition mold. The distance between the two electrodes was controlled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com