Novel anode electroplating liquid and acidic copper electroplating process using same

An anodic electroplating solution and acid electroplating technology, which is applied in the electrolytic process, electrolytic components, cells, etc., can solve the problems that the electroplating products cannot meet the quality requirements, the high cost of electroplating waste liquid treatment, and the unstable composition of the electroplating liquid, etc., to avoid the edge Increased effect, low cost of environmental protection treatment, avoiding the effect of large pressure on the electroplating tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

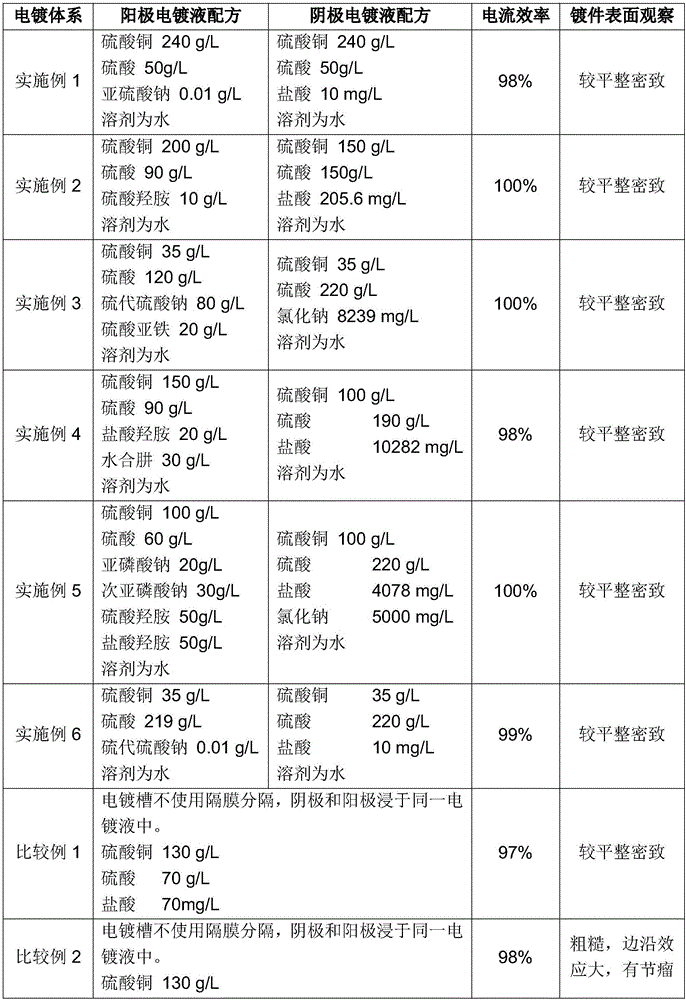

[0071] The components of the anolyte plating solution and the catholyte plating solution used in this example are shown in Table 1.

[0072] Step 1: Dissolve the components specified in Table 1 in water according to the proportioning ratio, and prepare anodic plating solution and cathodic plating solution respectively; use a diaphragm to separate the electroplating tank into a cathode tank and an anode tank, and an insoluble anode plate is provided at the bottom of the anode tank;

[0073] Step 2: Pour the anode plating solution obtained in step 1 into the anode tank of the electroplating tank, pour the cathodic plating solution into the cathode tank of the electroplating tank, and weigh the initial weight of the cathodic plated piece, and measure its weight to be 500.5g;

[0074] Step 3: Put phosphorus-free copper powder into a titanium metal hanging basket, and wrap the titanium metal hanging basket with a chemical fiber cloth bag as an anode; immerse the anode in the anode p...

Embodiment 2

[0077] The components of the anolyte plating solution and the catholyte plating solution used in this example are shown in Table 1.

[0078] The steps of this embodiment are the same as those of Embodiment 1. The initial weight of the cathode-plated piece measured in step 1 is 499.7g, and after the electroplating finishes, the measured plated piece weighs 1834.3g.

Embodiment 3

[0080] The components of the anolyte plating solution and the catholyte plating solution used in this example are shown in Table 1.

[0081] The steps of this embodiment are the same as those of Embodiment 1. The initial weight of the cathodic plated piece measured in step 1 is 500.2g, and after the electroplating finishes, the measured plated piece weighs 1820.4g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com