Copper dissolving resisting stannum-copper lead-free brazing filler metal alloy

A lead-free solder, tin-copper technology, applied in the direction of metal processing equipment, welding/cutting media/materials, welding media, etc., can solve the problem of less research work on improving the resistance to dissolution of copper, and the lack of quantitative research on the inhibition of solder copper dissolution Test comparison data and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

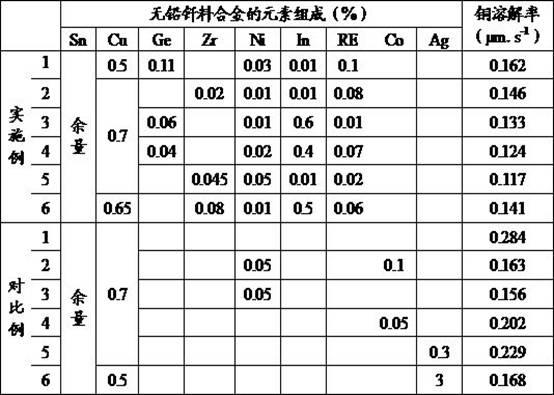

[0012] Examples of the present invention, comparative examples and copper dissolution rates are shown in Table 1, and the contents of all elements are weight percentages.

[0013] Table 1 Examples, Comparative Examples and Copper Dissolution Rate of Resistant Copper-Sn-Cu Lead-Free Solder Alloy

[0014]

[0015] In order to prove the performance of the examples of the present invention in terms of resistance to copper dissolution, the examples and comparative examples were compared under the same test conditions.

[0016] Test method for copper dissolution rate: 【1、2】 Use the copper wire with a diameter of 1mm to be immersed in the solder pool for a certain period of time and then take it out. Refer to the following formula to calculate the change in diameter of the copper wire before and after immersion:

[0017] V=1 / 2(d 0 -d f / t)

[0018] Among them, V is the copper dissolution rate; t is the time when the copper wire is immersed in the solder pool, d 0 is the origi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com