Method for synchronously roughening both surfaces of electrolytic copper foil and equipment thereof

An electrolytic copper foil and roughening technology, which is applied in the field of electrolytic copper foil, can solve the problems of high energy consumption and high production cost, and achieve the effects of uniform and fine surface contour, improved volume-to-capacity ratio, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings, but it does not constitute any limitation to the present invention.

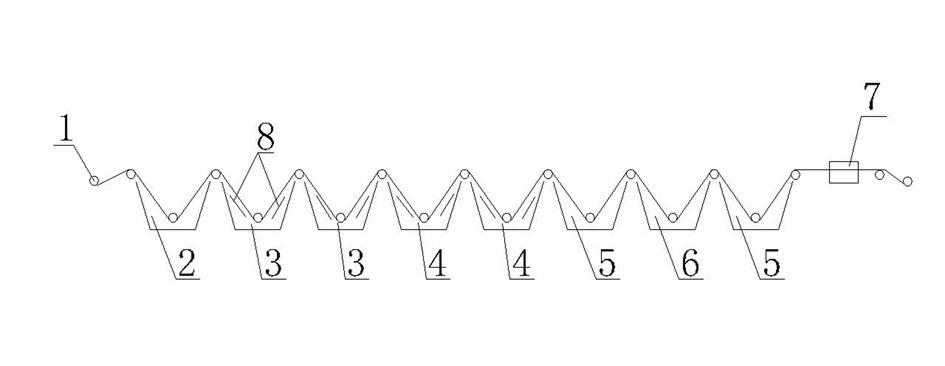

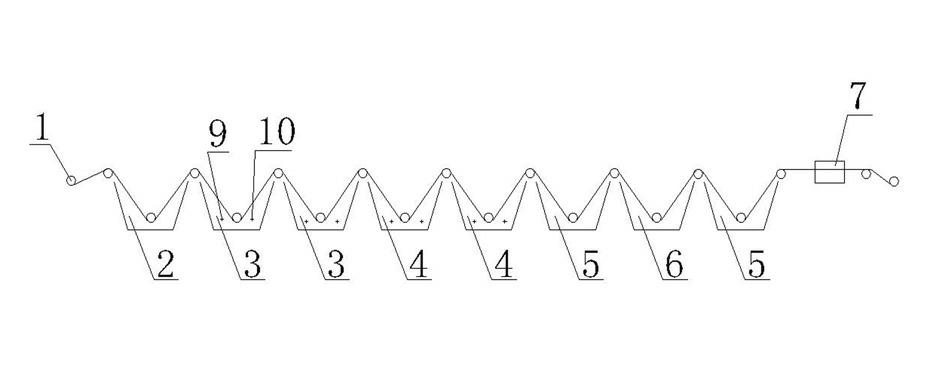

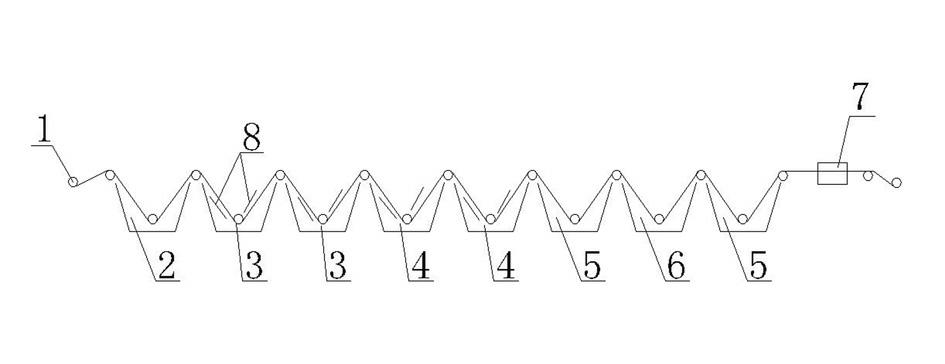

[0020] refer to image 3 , Figure 4 As shown in FIG. 1 , a device for double-sided synchronous roughening of electrolytic copper foil includes pickling tank 2, roughening tank 3, curing tank 4, water washing tank 5 and oxidation prevention tank 6. Among them, the bottoms of the roughening tank 3 and the curing tank 4 are respectively provided with a first electrolyte PVC inlet pipe 9 and a second electrolyte PVC inlet pipe 10, and a third electrolytic solution is provided at a position 10 cm away from the upper end of the roller in the liquid. The liquid PVC inlet pipe 11 is used to change the flow structure of the solution in the roughening tank and the solidification tank, to ensure the flow process requirements of the roughening solution and the solidification solution, and to make the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com