Solid-oxide fuel battery and manufacturing method thereof

A solid oxide and fuel cell technology, used in solid electrolyte fuel cells, fuel cells, and final product manufacturing, etc., can solve the problems of inconsistent temperature coefficients of connectors, reduced efficiency, and increased loss, and achieve stable and reliable production processes. Stable and reliable performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

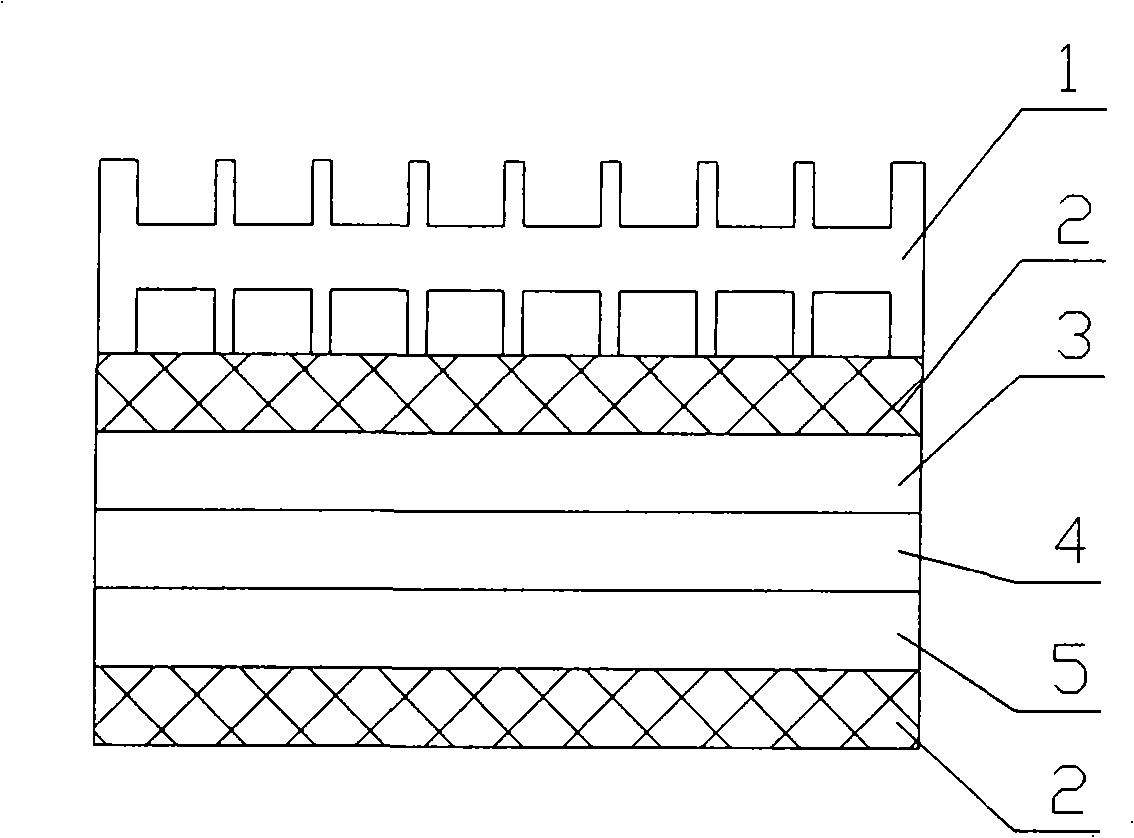

[0049] A flat-plate solid oxide fuel cell supported by a metal mesh, including a panel, a pole, and a battery cell group. The battery cell group is assembled from a battery cell and a connector 1. The battery cell has a stainless steel metal mesh 2 on both sides. It consists of anode 3, electrolyte 4 and cathode 5. The battery core is in the shape of a cuboid.

Embodiment 2

[0051] A method for manufacturing a low-cost planar solid oxide fuel cell, the battery core group is assembled by battery cores and connectors, and the preparation of the battery cores includes the following process:

[0052] 1. Metal mesh plating

[0053] The anode metal copper, nickel, zirconium, iridium, scandium, electrolyte metal zirconium, iridium, scandium and cathode metal lanthanum, manganese are sequentially plated layer by layer on the stainless steel metal mesh, with a thickness of 10 microns.

[0055] After electroplating, the stainless steel metal mesh is welded on the other side by friction welding;

[0056] 3. Preparation of ceramic battery cells by micro-arc oxidation

[0057] The anode metal, the electrolyte metal and the cathode metal are oxidized by a micro-arc oxidation method to prepare bare ceramic battery cores. When micro-arc oxidation is used to prepare ceramic battery cores, the metal mesh on both sides is used as th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com