Anode electroplating device

An anode device, anode technology, applied in the direction of electrodes, current conduction devices, etc., can solve the problems of product scorch, coating thickness, affecting product quality and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

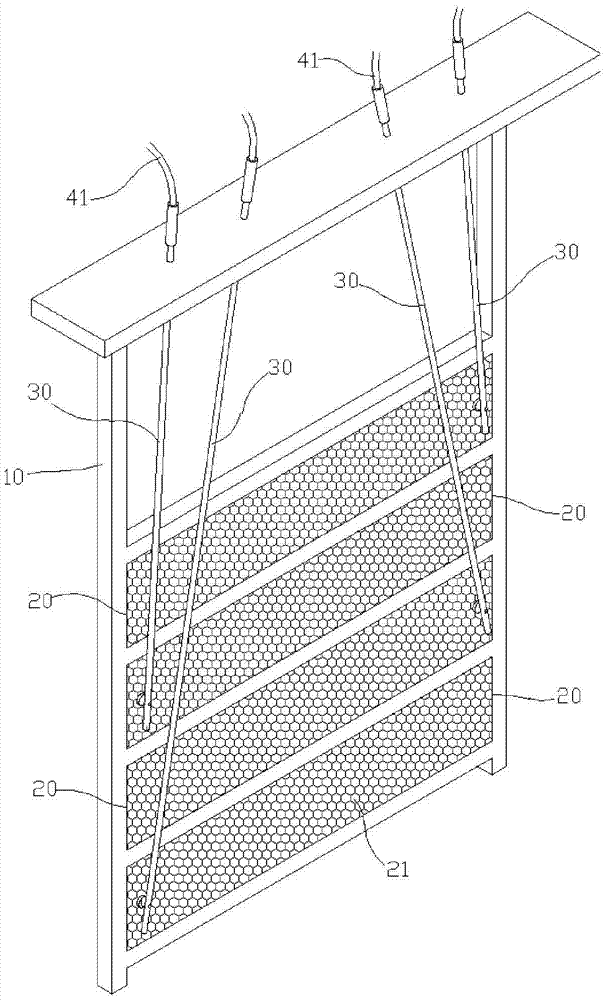

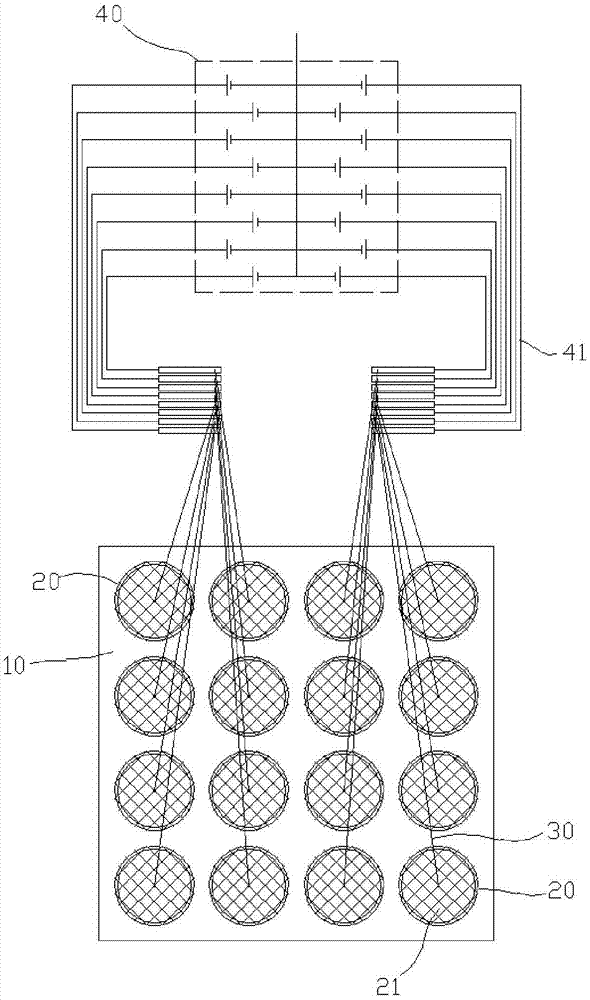

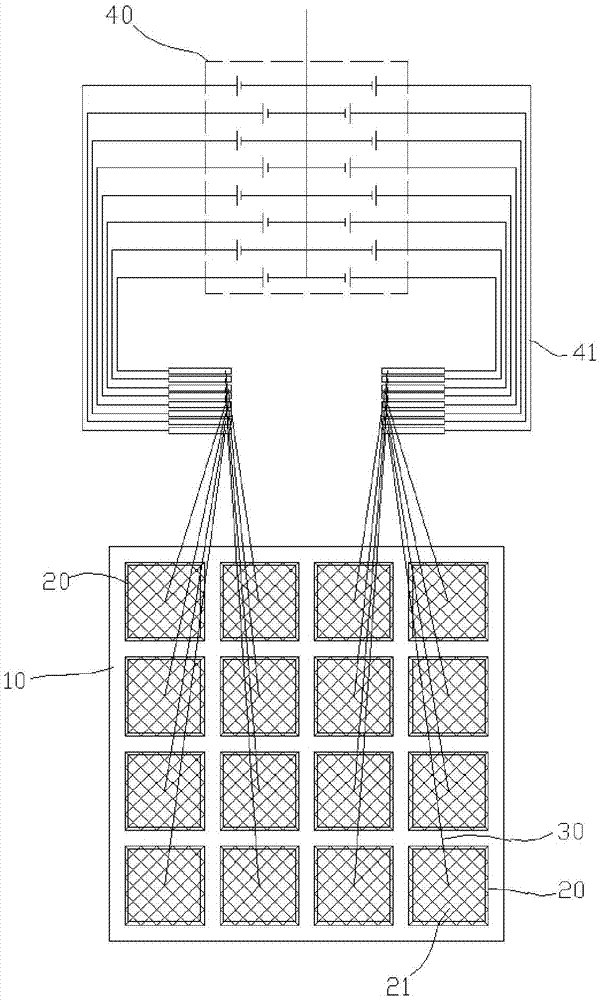

[0036] The present invention mainly provides an electroplating anode device that can adjust the power distribution state according to the product shape or product hanging configuration, such as figure 1 As shown, the electroplating anode device of the present invention has a frame body 10, and a plurality of anode parts 20; wherein, each of the anode parts 20 is arranged on the frame body 10 in a mutually insulated state, and a plurality of conductive parts 30 are also provided. They are respectively electrically connected to each of the anode parts 20 .

[0037] In principle, for the electroplating anode device of the present invention, in practical application, the paired electroplating anode devices can be placed on both sides of the electroplating tank relative to the cathode, and the products to be electroplated are hung on the cathode, so that they are respectively on the anode end. Under the state of inputting current to the cathode terminal, the electroplating solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com