Pipe dropping device for laser pipe cutter

A blanking device and pipe cutting machine technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of affecting the processing accuracy of steel pipes, inconvenient blanking, inapplicability, etc., to reduce labor intensity, blanking Convenience and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

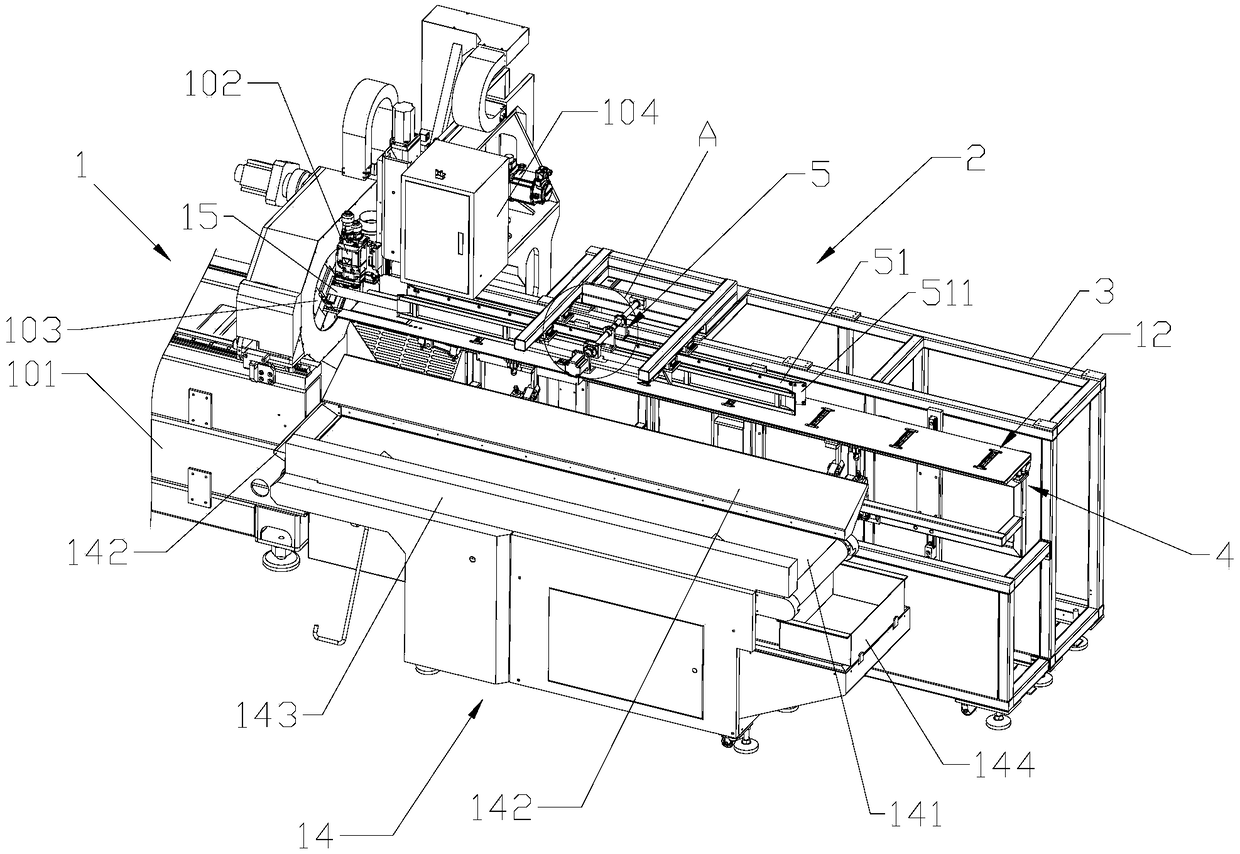

[0047] refer to figure 1 , this embodiment discloses a pipe blanking device for a laser pipe cutting machine, which is used in conjunction with a laser cutting machine 1, and includes a pipe support device 2 and a receiving and conveying assembly 14. One end of the material, the pipe support device 2 includes a mounting bracket 3 , a horizontal support assembly 4 and an anti-swing assembly 5 arranged on the mounting bracket 3 .

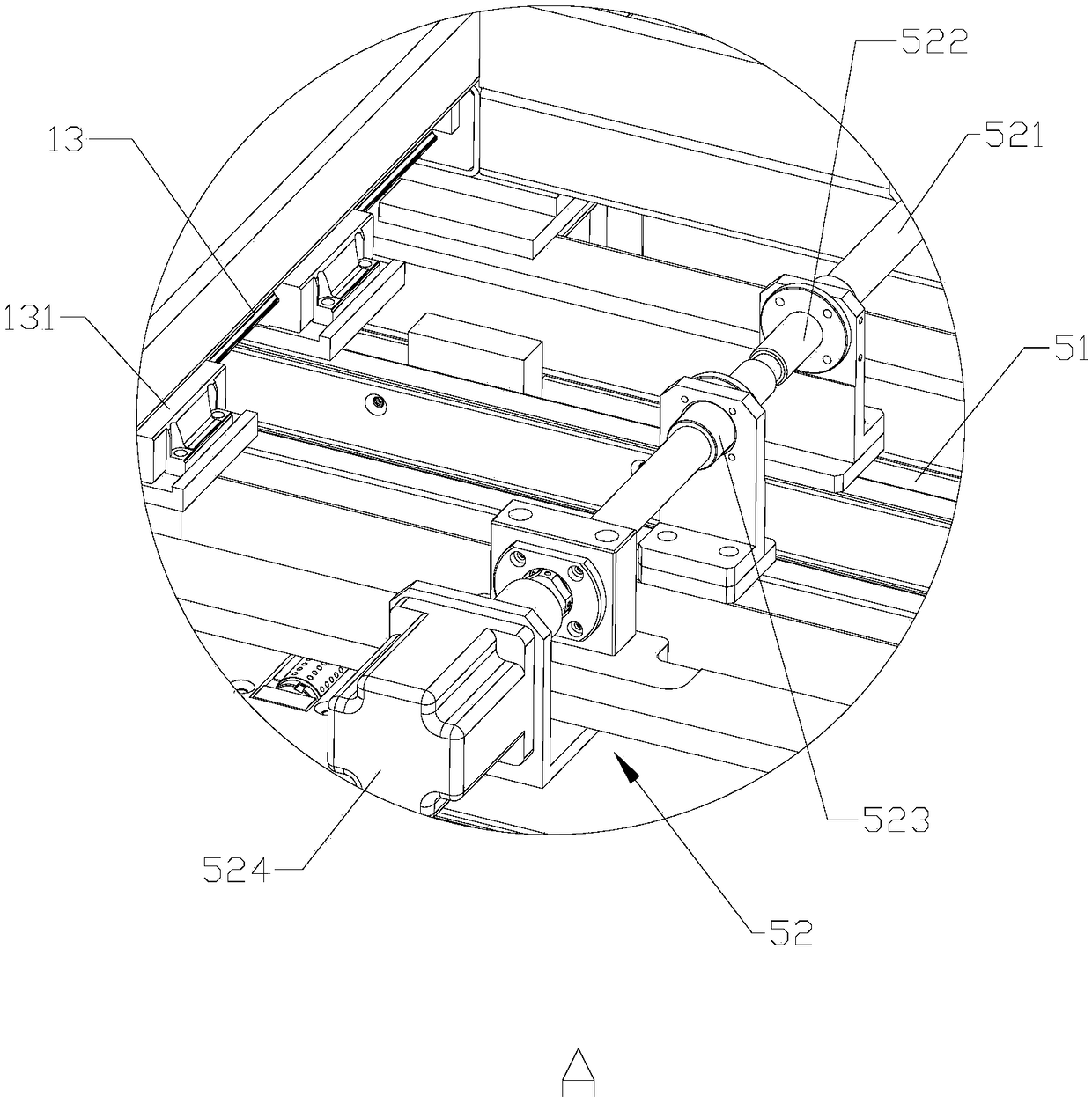

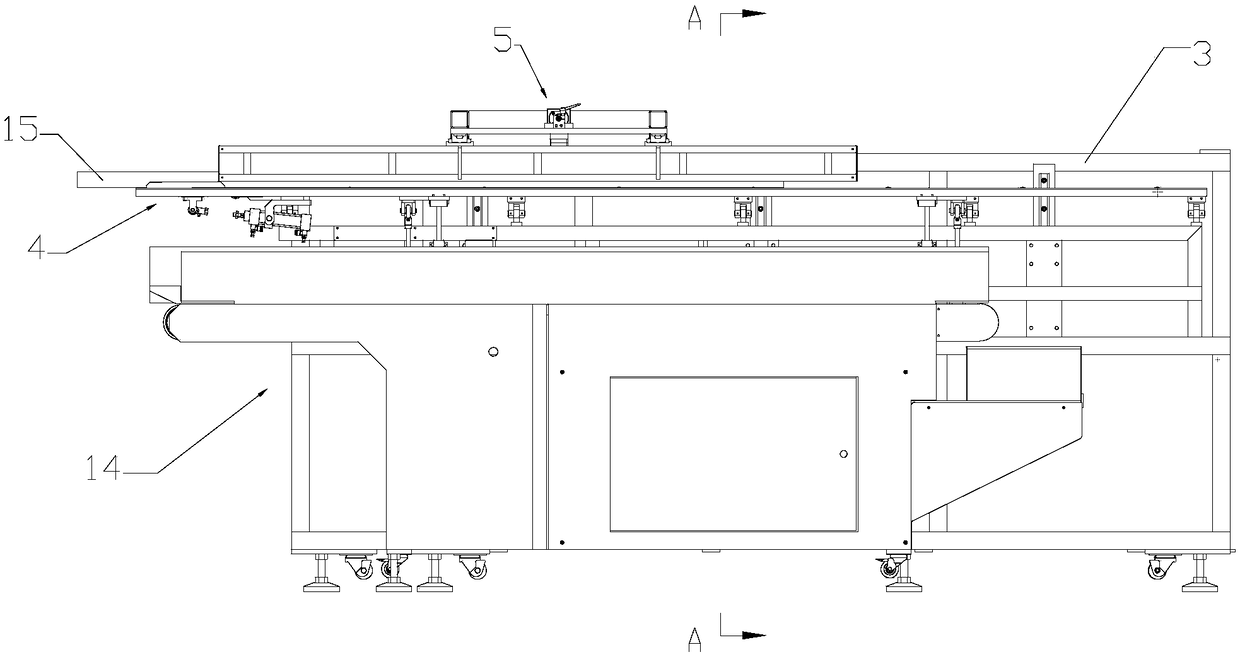

[0048] refer to image 3 as well as Figure 4 The mounting bracket 3 is provided with a lifting drive assembly 6 that drives the horizontal support assembly 4 to lift vertically. The horizontal support assembly 4 includes a support base plate 41 and a support platform 42. The support base plate 41 is movable in the vertical direction relative to the mounting bracket 3. At least one vertical guide rail 8 is fixedly arranged on the mounting bracket 3, at least one vertical slider 81 is fixedly arranged on the support base plate 41, and the vertical sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com