Diffusion drainage device of range hood

A range hood and oil fume technology, which is applied in the field of pressure diffusion and drainage devices, can solve problems such as increased user complaints, backflow of smoke, high back pressure, etc., and achieve the effect of improving the diffusion of oil fume and improving the pressure distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

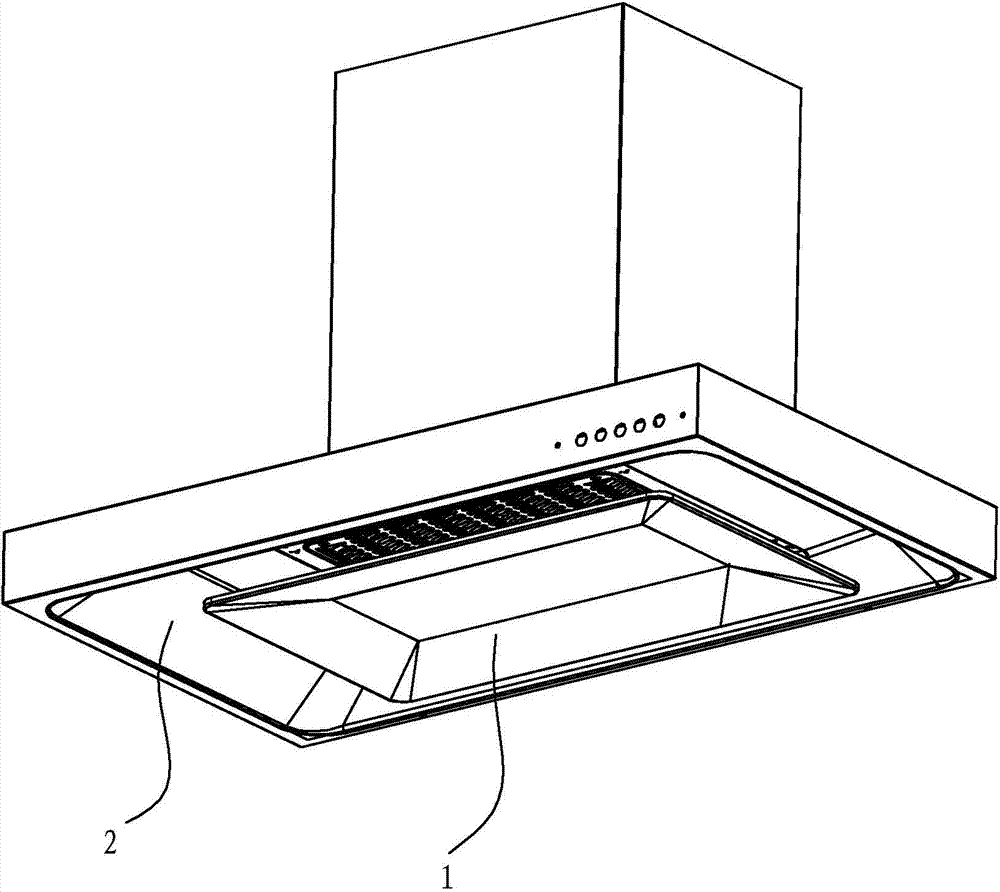

[0027] Such as figure 1 The shown smoke guiding device of the top suction range hood includes a diffuser and drainage smoke control plate 1 which is arranged facing the air inlet of the smoke collection hood of the top suction range hood, and the inside of the smoke collection hood 2 of the top suction range hood is A smoke collection cavity is formed, and the diffuser and drainage smoke control plate 1 has a concave structure with a high center and a low periphery, so that the diffuser and drainage smoke control plate 1 is combined with the smoke collection hood 2 to make the collection of the top suction range hood The smoke cavity is formed with two upper and lower double-layer concave cavities, which also makes the caliber of the oil fume channel formed between the diffuser and drainage smoke control plate and the smoke collection hood gradually shrink.

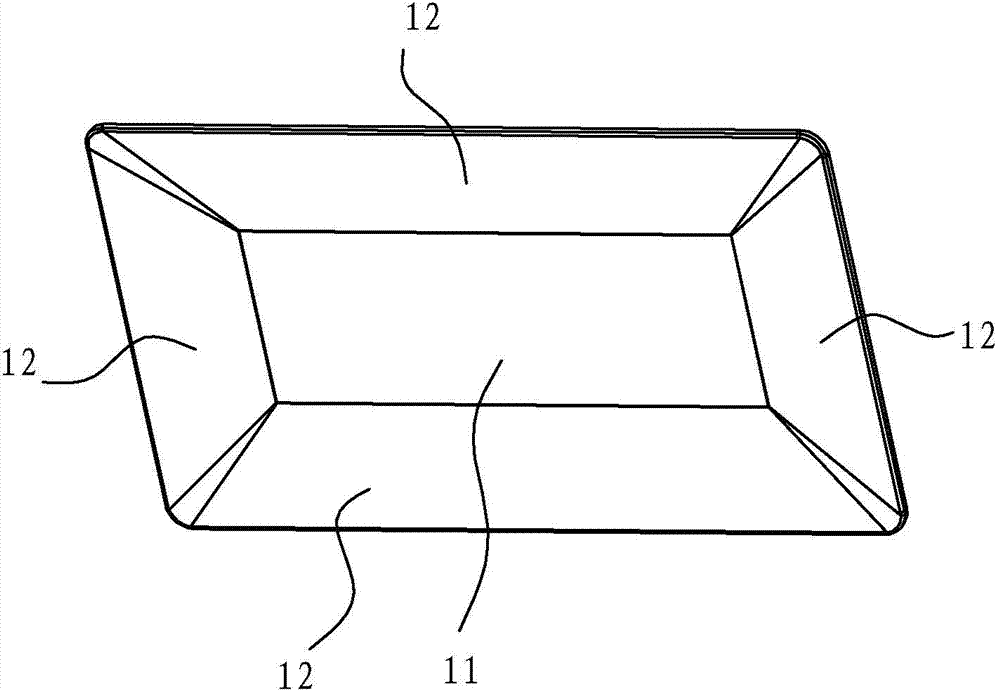

[0028] In this embodiment, the diffuser and drainage smoke control plate 1 includes a middle plane 11 and surrounding s...

Embodiment 2

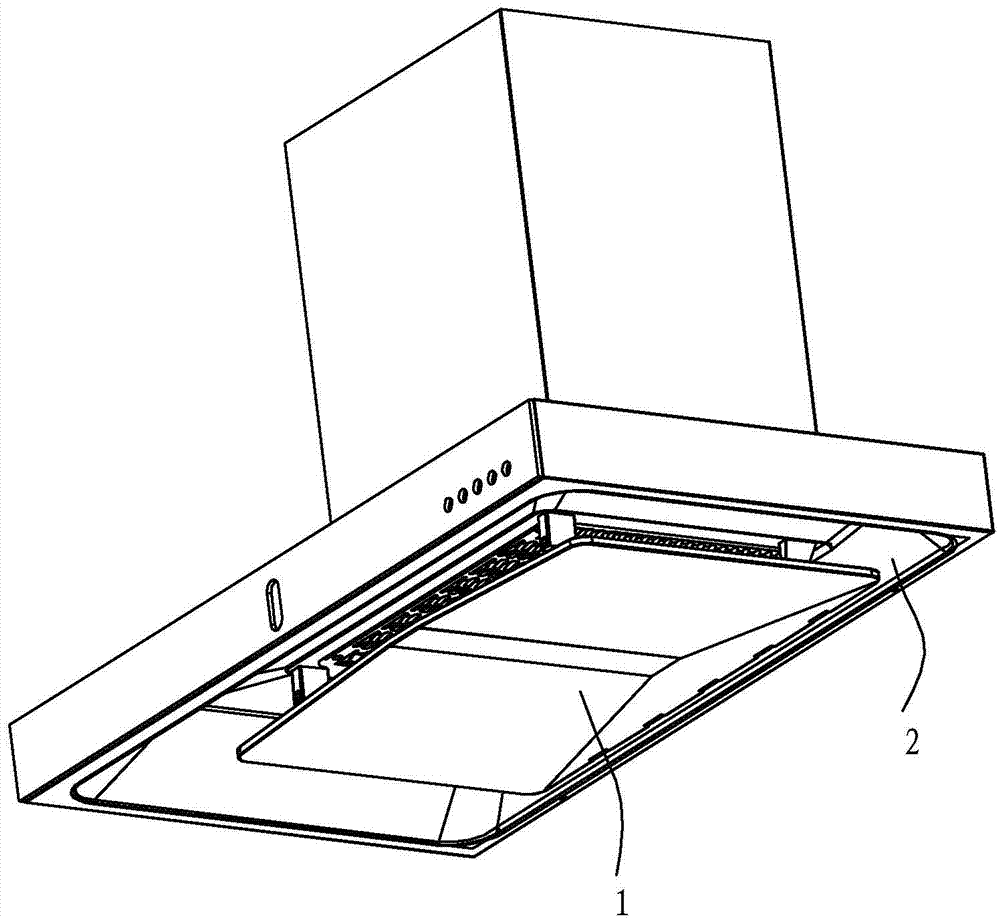

[0031] The difference from Embodiment 1 is that the rear side of the diffuser and drainage smoke control plate 1 is hinged on the smoke collection hood 2, and the front side of the diffuser pressure drainage smoke control plate 1 is connected with the smoke collection hood 2 through buckles 3, see image 3 , 4 As shown, and in this embodiment, the area of the middle plane 11 of the diffuser and drainage smoke control plate 1 is smaller than the area of the middle plane in Embodiment 1, see Figure 5 shown.

Embodiment 3

[0033] The difference from Embodiment 1 is that when the diffuser and drainage smoke control plate 1 is installed, the front side is higher and the rear side is lower, and the diffuser and drainage smoke control plate 1 is provided with a strip-shaped oil cup 4 at the rear, see Figure 6 shown. The diffuser, drainage, and smoke control plate 1 is inclined backward, and a strip-shaped oil cup is arranged on the rear side, which is convenient for guiding oil and accepting and storing oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com