Novel type gripping mechanism with interval size being adjustable

An adjustable and spacing technology, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of inability to adjust the grasping distance, inflexible adjustment, small application range, etc., and achieve good market application value, compact structure, and adaptable range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

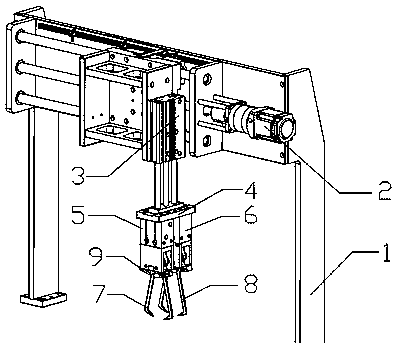

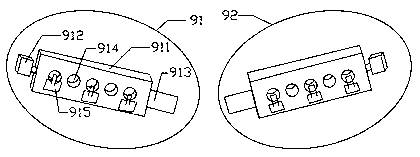

[0021] Embodiment 1, a new grabbing mechanism with adjustable pitch size, including a support frame 1, and also includes a horizontal displacement assembly 2 located on the support frame 1, an assembly lifting cylinder 3, an assembly mounting plate 4, a first grab Take the power assembly 5, the first positioning assembly 9, the second grasping power assembly 6, the second positioning assembly, the first jaw set 7 and the second jaw set 8; the fixed end of the horizontal displacement assembly 2 Installed on the crossbeam of the support frame 1, the working end of the horizontal displacement component 2 is connected to the fixed end of the assembly lifting cylinder 3, and the working end of the assembly lifting cylinder 3 is connected to the upper wall of the assembly mounting plate 4 downwards. The fixed ends of the first grabbing power assembly 5 and the second grabbing power assembly 6 are installed on the lower part of the assembly mounting plate 4 and arranged front and rear...

Embodiment 2

[0024] Embodiment 2, the lower part of the assembly mounting plate 4 is located between the first grabbing power assembly 5 and the second grabbing power assembly 6, and a horizontal adjustment cylinder is provided, and the fixed end of the first grabbing power assembly 5 Slidingly connected with the lower part of the assembly mounting plate 4, the working end of the horizontal positioning cylinder is connected with the fixed end of the first grabbing power assembly 5 through a connecting slide plate; further, the horizontal positioning cylinder works to push the first grabbing power assembly 5 along the The assembly mounting plate 4 slides horizontally, thereby adjusting the distance between the first jaw set 7 and the second jaw set 8, so as to clamp products of different sizes.

Embodiment 3

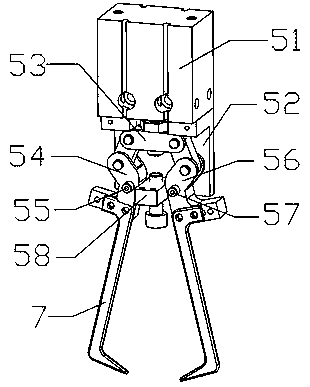

[0025] Example 3, such as image 3As shown, the first grabbing power assembly 5 includes a first lifting cylinder 51, a first mounting bracket 52, a first connecting rod assembly 53, a first arc-shaped rotating member 54, a first rotating shaft 55, and a second arc-shaped rotating 56, the second rotating shaft 57 and the first spring buffer 58, the fixed end of the first lifting cylinder 51 is fixedly connected with the bottom of the assembly mounting plate 4, the upper end of the first mounting frame 52 is connected with the first lifting cylinder 51 The lower part of the fixed end is connected, and the working end of the first lifting cylinder 51 is connected with the upper end of the first connecting rod assembly 53. The upper end of the arc-shaped rotating part 56 is pivotally connected, and the middle parts of the first arc-shaped rotating part 54 and the second arc-shaped rotating part 56 are installed on the first mounting frame 52 by the first rotating shaft 55 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com