Novel picture frame hanging rack

A new type of technology for picture frames, applied to picture frames, mirrors, household utensils, etc., can solve the problems of inconsistency and inconsistency of hanging hole spacing, etc., and achieve the effect of strong practicability, novel structure and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

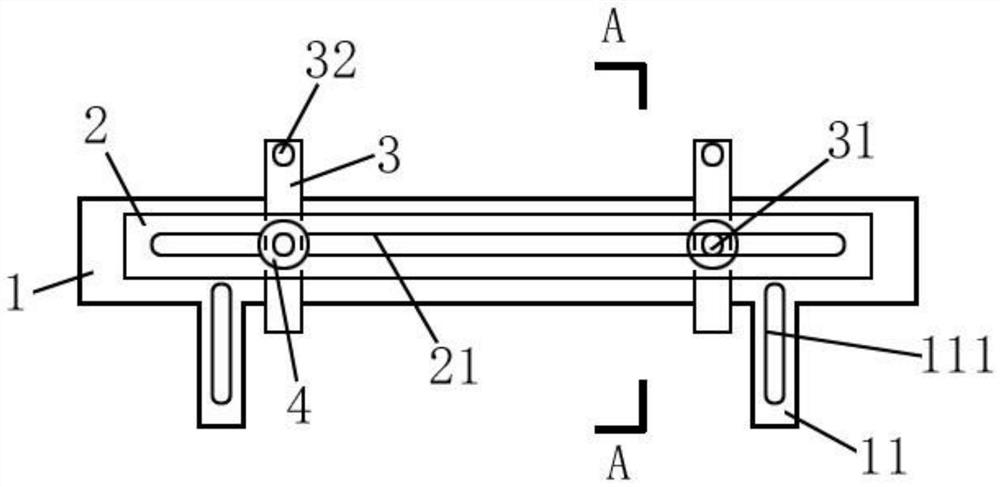

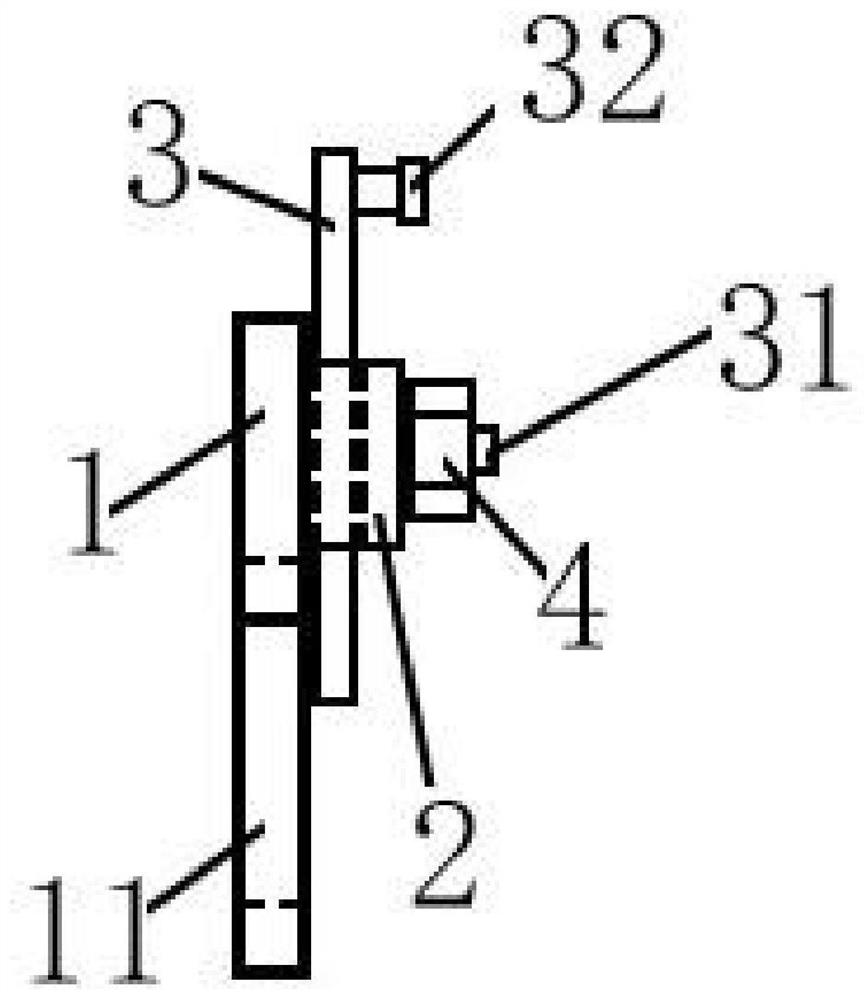

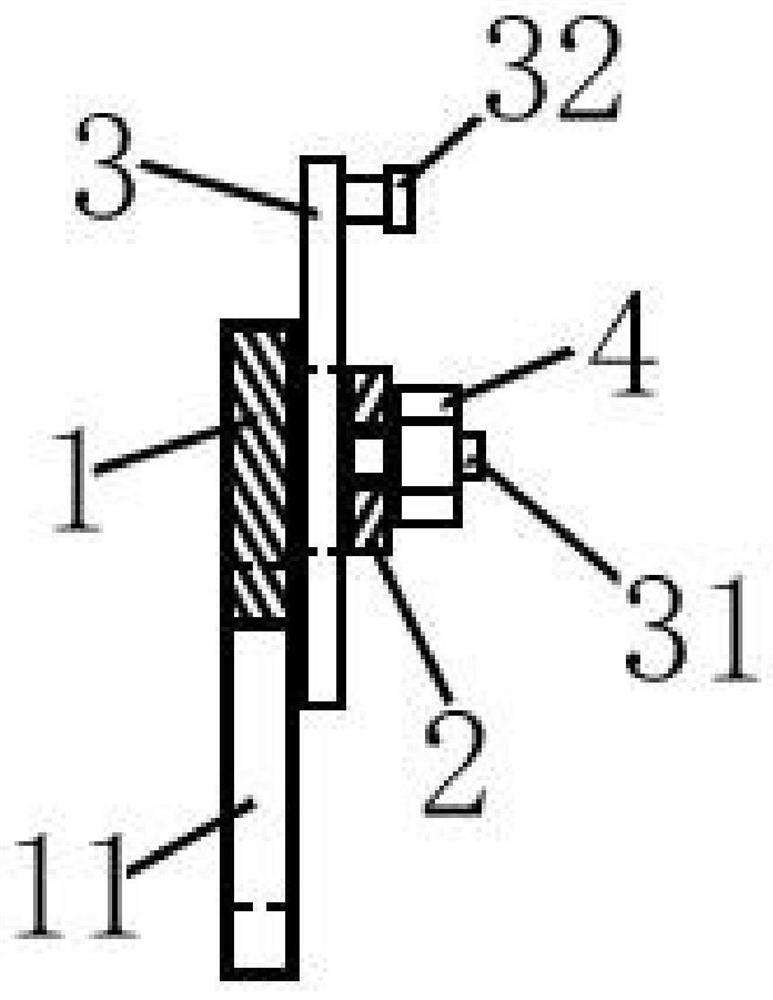

[0023] Such as figure 1 , figure 2 , image 3 As shown, a novel picture frame hanger is composed of a rectangular seat piece 1, a vertical adjustment piece 11, an arched sliding piece 2, a traverse piece 3, and a tightening nut 4. It is characterized in that,

[0024] The bottom of the rectangular seat piece 1 is integrally formed by stamping with two left and right vertical adjustment pieces 11, and the middle part of each vertical adjustment piece 11 is punched with a vertical strip-shaped through hole 111;

[0025] The rectangular seat piece 1 and the vertical adjustment piece 11 are combined to form a horizontal height adjustment mechanism;

[0026] Each vertical elongated through hole 111 can realize the purpose of fastening the level height adjustment mechanism on the wall by tightening the screw;

[0027] The middle part of the front side of the rectangular seat 1 is welded with an arched sliding piece 2, and the middle part of the arched sliding piece 2 is punched ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com