Steel wire drawing and winding mechanism

A technology for a wire winding mechanism and a steel wire is applied in the field of wire drawing and winding mechanism, which can solve the problems of a single winding mechanism, unable to prevent the steel wire from being wound in one place, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

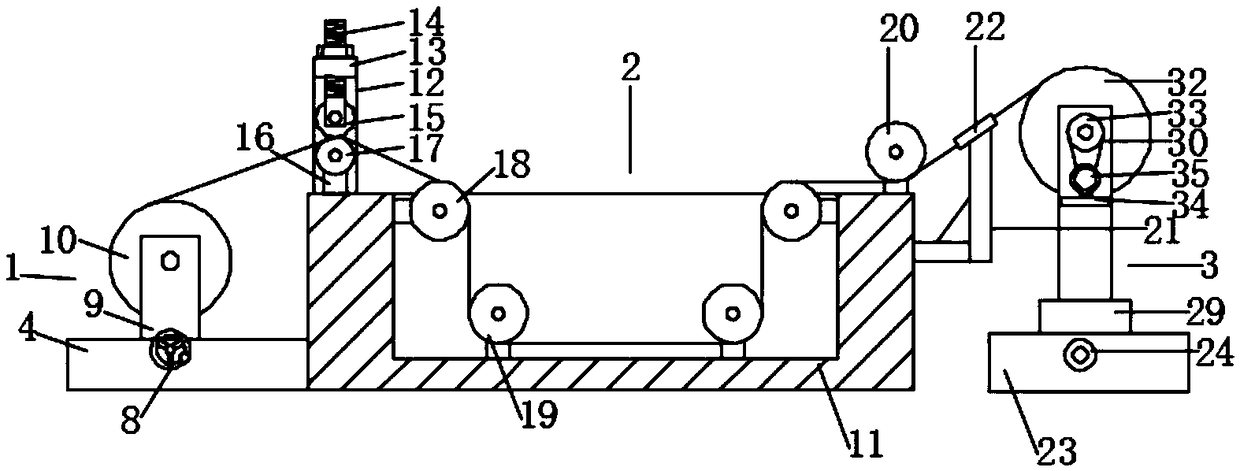

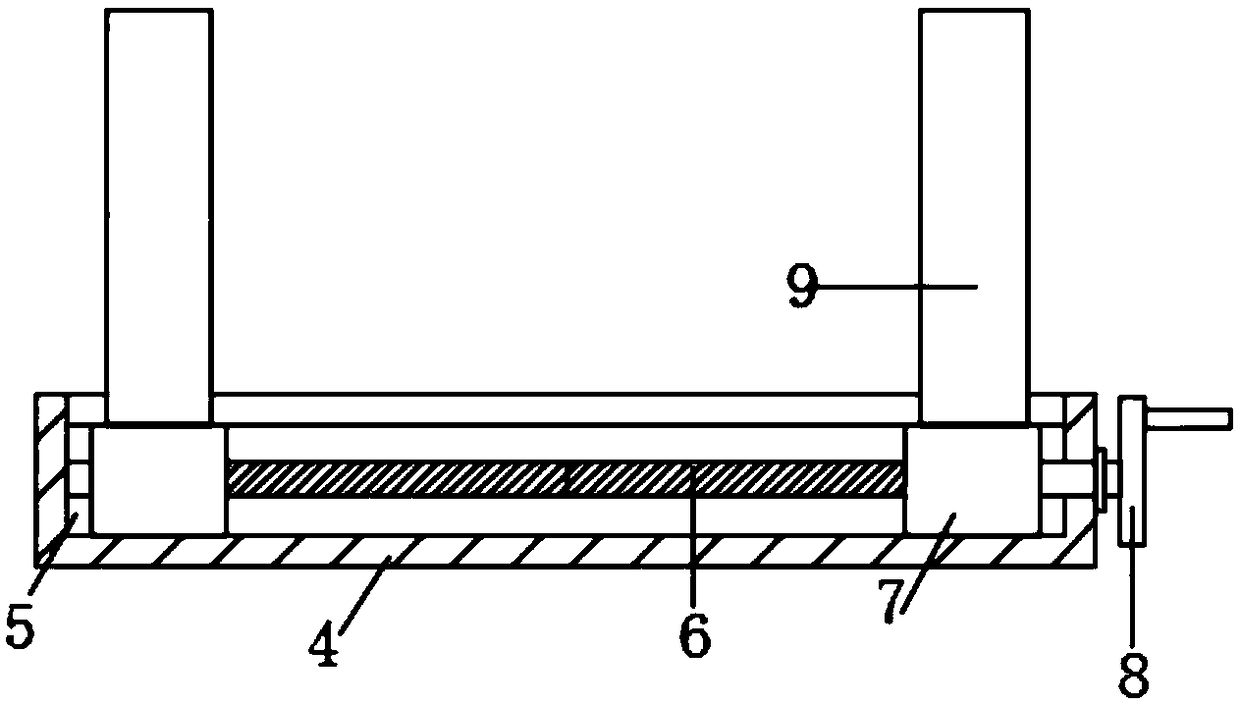

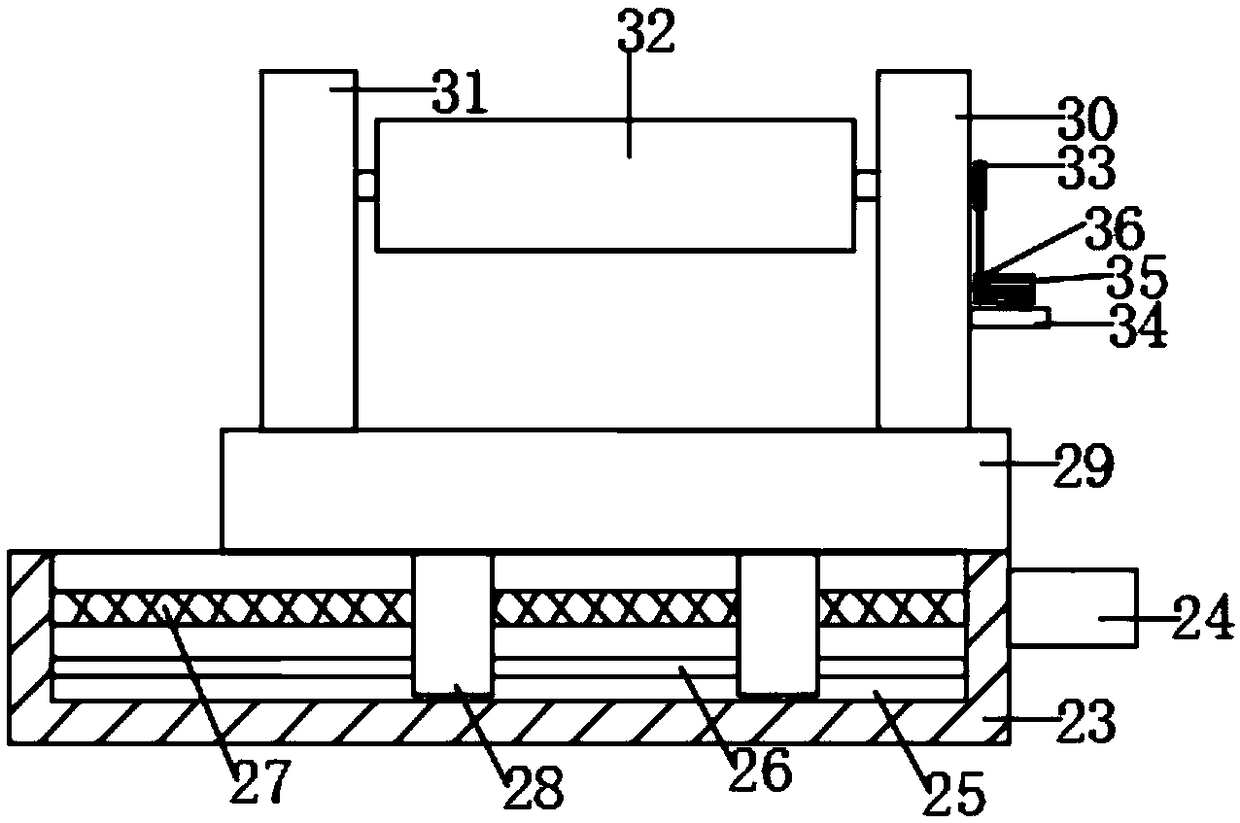

[0019] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a steel wire drawing and receiving mechanism, including a wire releasing mechanism 1, a drawing mechanism 2 and a wire receiving mechanism 3, and one side of the wire releasing mechanism 1 is provided with a drawing Mechanism 2, and the side of the drawing mechanism 2 away from the wire releasing mechanism 1 is provided with a wire receiving mechanism 3, and the wire releasing mechanism 1 is composed of a first fixed seat 4, a distance adjusting chute 5, a distance adjusting screw rod 6, The distance adjustment slider 7, the distance adjustment handwheel 8, the fixed pillar 9 and the pay-off roller 10 are composed of a distance adjustment chute 5 at the middle position of the top of the first fixed seat 4, and the distance adjustment chute 5 inner wall A distance-adjusting screw rod 6 is rotationally connected between the corresponding two sides, and the outside of the dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com