Dual-power one-stage molding wall grooving machine

A dual-power, slotting machine technology, applied in construction, building construction, etc., can solve the problems of increased operator load, increased slotting process, poor power, etc., to ensure consistency, strong cutting power, and reduce load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the present invention, the present invention will be further described below with reference to the accompanying drawings and specific embodiments.

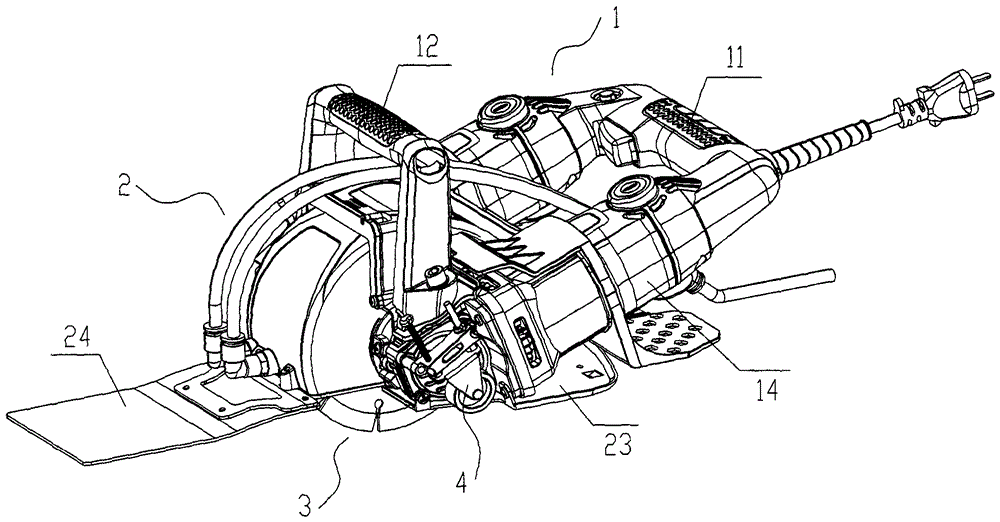

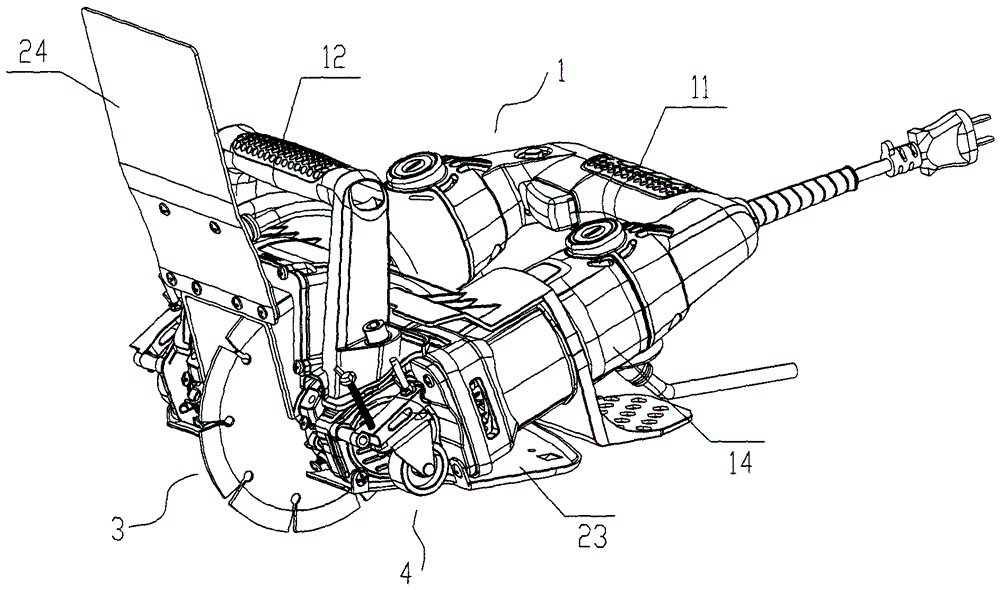

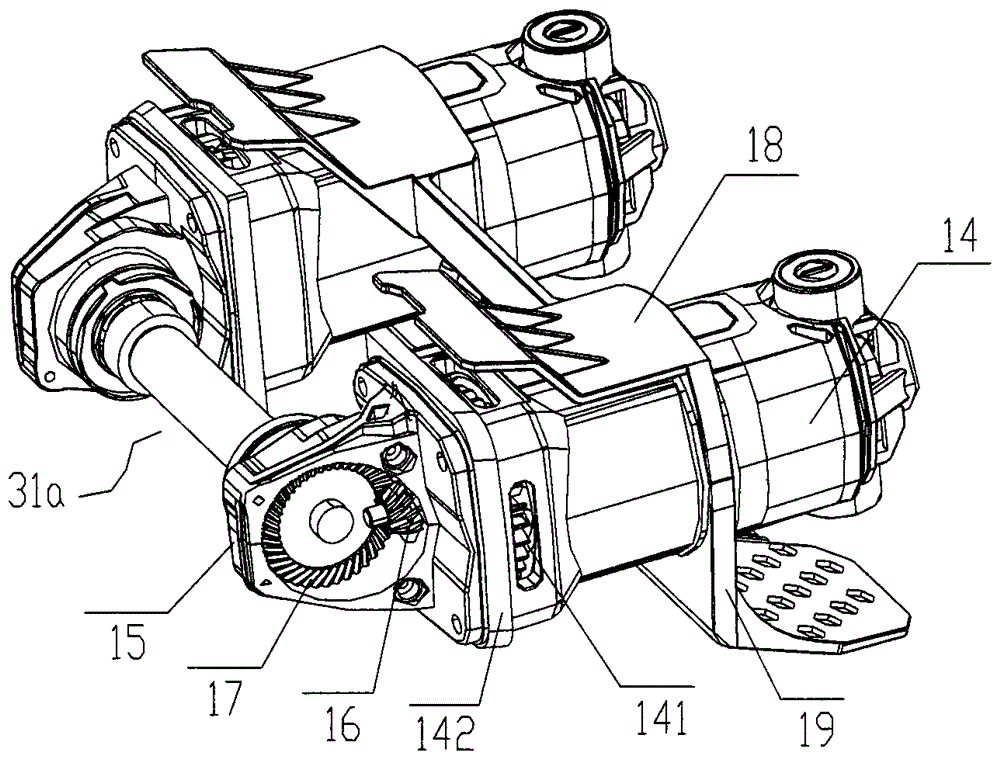

[0026] Such as Figure 1 to Figure 9 As shown, a wall slotting machine with dual power and one-time molding includes two motor covers 14 that are side by side and spaced apart. The motor cover 14 is provided with a motor 13, and the tail of the motor cover 14 passes through a horizontal handle 11 in the horizontal direction. connect. The front end of motor cover 14 is provided with front cover 142, and front cover 142 is provided with axle seat 15, is provided with the cutting assembly 3 that is made of cutter shaft 31a and blade 33 between left and right axle seats 15, the motor shafts of left and right two motors 13 respectively Engaged with the two ends of the cutter shaft 31a, the upper ends of the left and right shaft seats 15 are connected by the vertical handle 12 in the vertical direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com