Coal mine vertical shaft inspection device and laser scanning defect detection method

A shaft and shaft technology is applied in the field of inspection devices for shaft shafts in coal mines to achieve the effects of strong load capacity, good stability and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

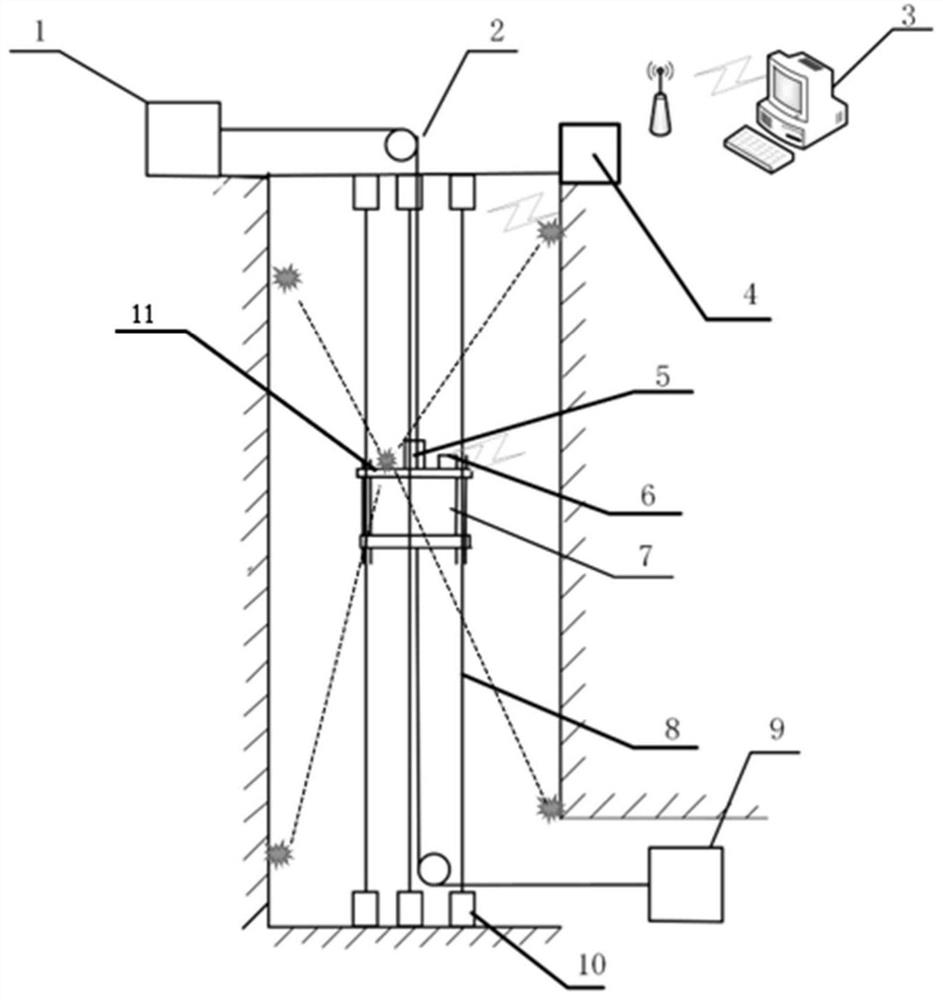

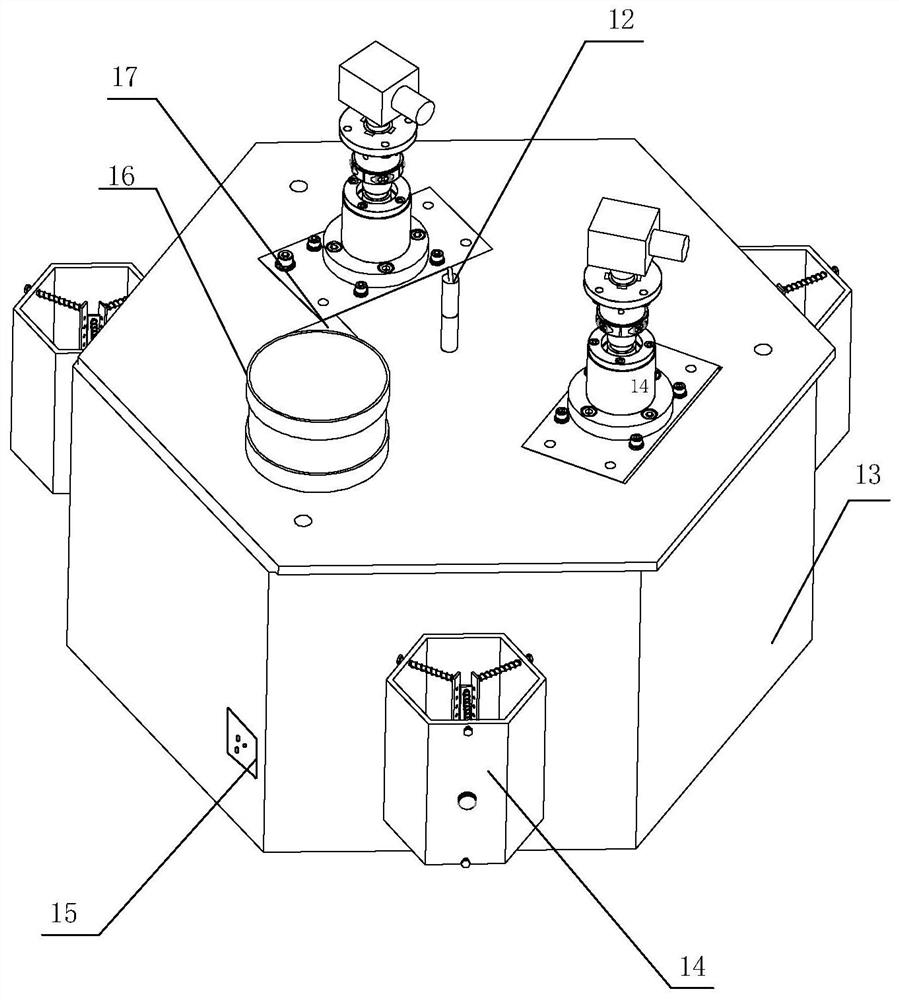

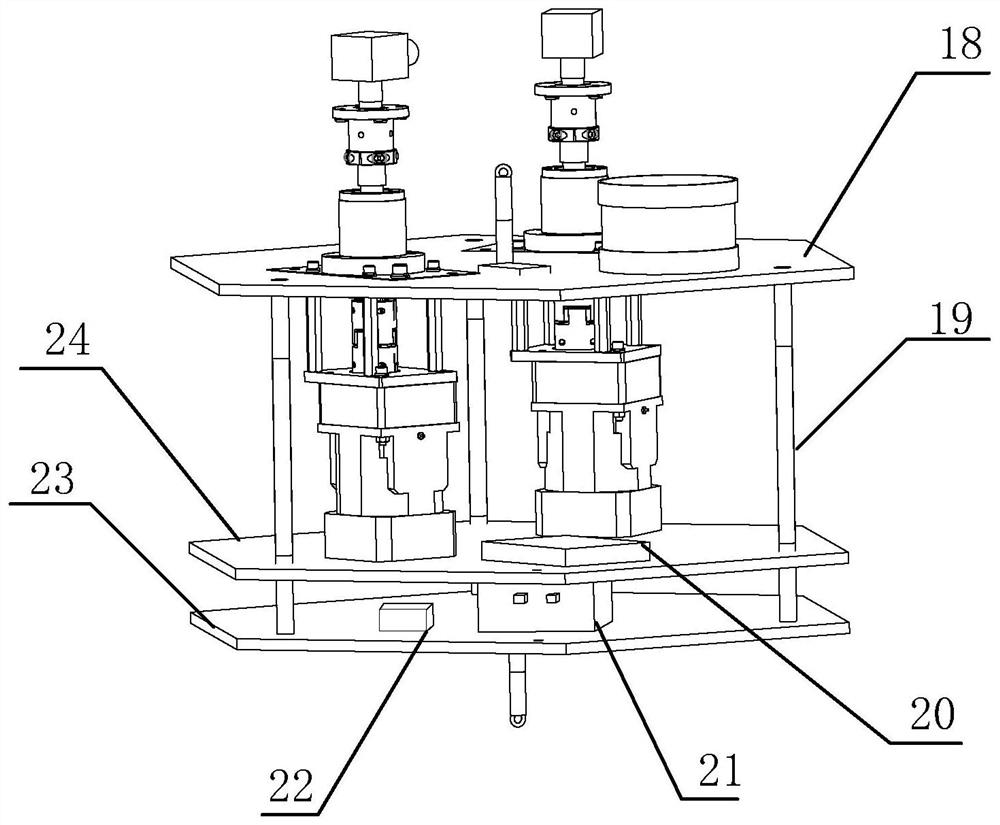

[0040] Such as figure 1 As shown, the coal mine shaft inspection device of the present invention mainly includes an upper driving device 1, a pulley 2, a ground data processing system 3, a ground charging pile 4, a laser radar and an image acquisition platform 5, a wireless communication module 6, a patrol Inspection device body 7, guide wire rope 8, lower driving device 9, tensioning device 10, positioning system 11.

[0041] The external driving device includes an upper driving device 1 and a lower driving device 9 , the upper driving device is located above the inspection device body 7 , and the lower driving device 9 is located below the inspection device body 7 . The upper driving device mainly includes a driving motor, a coupling, a winding drum, and a rope. The driving motor drives the winding roller to rotate through the shaft coupling, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com