Automatic telescopic movable platform vehicle

An automatic retractable and platform trolley technology, applied in the field of mobile platform trolleys, can solve problems such as laborious, time-consuming moving and inconvenient use of ladders, and achieve the effects of stable movement, smooth up and down movement, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

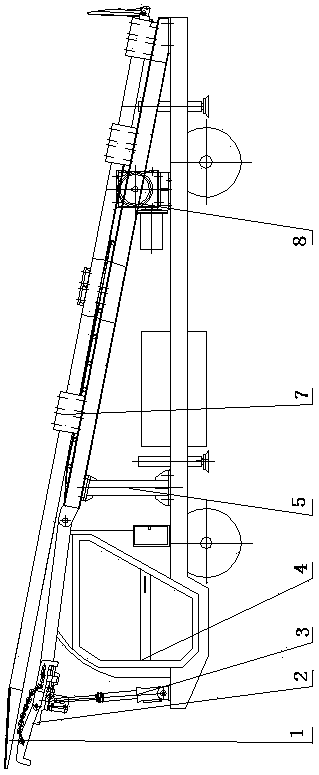

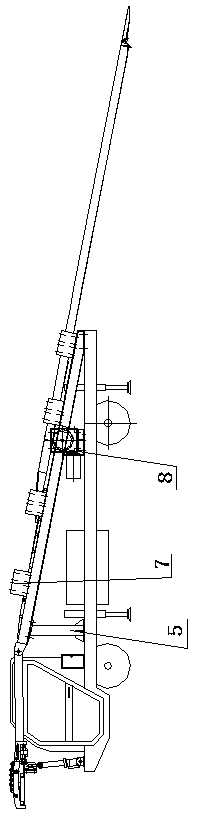

[0036] An automatic telescopic mobile station trolley, which consists of: a telescopic ladder composition 1 and a special electric vehicle 4, the two ends of the telescopic ladder composition are respectively installed on eight guiding device compositions 7 arranged side by side in the front and back, and the described The telescopic ladder composition is connected with the telescopic transmission device 8, the lower part of the guide device composition is fixedly connected with the support composition 5, and the front end of the support composition is equipped with a swing ladder composition 2, and the telescopic transmission device and the support composition are composed of are all installed on the special electric vehicle, the swing ladder composition is connected with the swing ladder lifting mechanism composition 3, and the swing ladder lifting mechanism composition is installed on the front end of the special electric vehicle;

[0037] The telescopic ladder composition c...

Embodiment 2

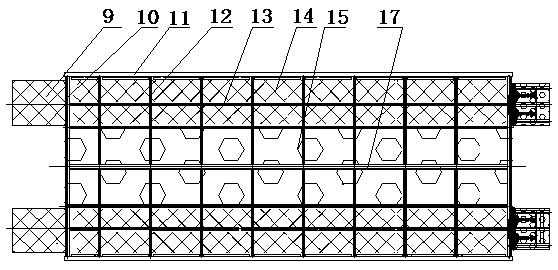

[0041]According to the automatic telescopic mobile station trolley described in embodiment 1, the telescopic ladder composition includes a side beam composition 11, and the side beam composition is fixedly connected with a plurality of crossbeams 12, and a plurality of the crossbeams are connected with a plurality of longitudinal beams. The beams 13 are fixedly connected, and the grid formed by the longitudinal beams and the beams on both sides of the telescopic ladder is covered with a first steel mesh 14, and the middle grid area formed by the telescopic ladder is paved with The first cover plate 15 can be disassembled and repaired. The front large crossbeam 10 on the telescopic ladder composition is fixedly connected to the fixed crossing board 9, and the rear large crossbeam on the telescopic ladder composition is composed of a movable crossing board 19. Connect, the bottom of the large crossbeam at the rear end on the composition of the telescopic ladder is equipped with a...

Embodiment 3

[0043] According to the automatic telescopic mobile station trolley described in embodiment 1 or 2, the guide device comprises a C-shaped guide seat 22, and a vertical guide device 20 and a horizontal guide device distributed up and down are arranged in the described C-shaped guide seat 21. The vertical guide device is provided with 4 sets of upper and lower limit guide linear motion roller support devices, and the horizontal guide device is provided with 2 sets of horizontal limit guide linear motion roller support devices.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tooth width | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com