Method and device for sorting wood according to colors and wood grains

A technology of wood and wood grain, applied in the field of equipment for realizing the method, can solve problems such as loss of enterprise economy and reputation, unstable quality of sorting, and decline in product quality, so as to improve accuracy and avoid individual differences and inconsistencies. , the effect of easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: a kind of method of sorting timber according to color and grain, it comprises the following steps:

[0021] a) Create category data: According to the factors of wood color, wood grain inclination angle and color spot ratio, create a category data of wood images to be classified. The color factor distinguishes three levels of color difference, and selects three representative wood samples and calibrates them with a video imaging device. The calibration colors are: FF9900 (R=255, G=153, B=0), F8CC34 (R=248, G = 204, B = 52), E3CF63 (R = 227, G = 207, B = 99); the inclination angle of wood grain is divided into two levels, the inclination angle is less than or equal to 5° for straight grain, and the angle is greater than 5° for twill grain; The factor of spot ratio is divided into three levels, the proportion of stain (wood grain color) is less than or equal to 1% of the board surface, the proportion of stain is 1-10% of the board surface, and the proportion ...

Embodiment 2

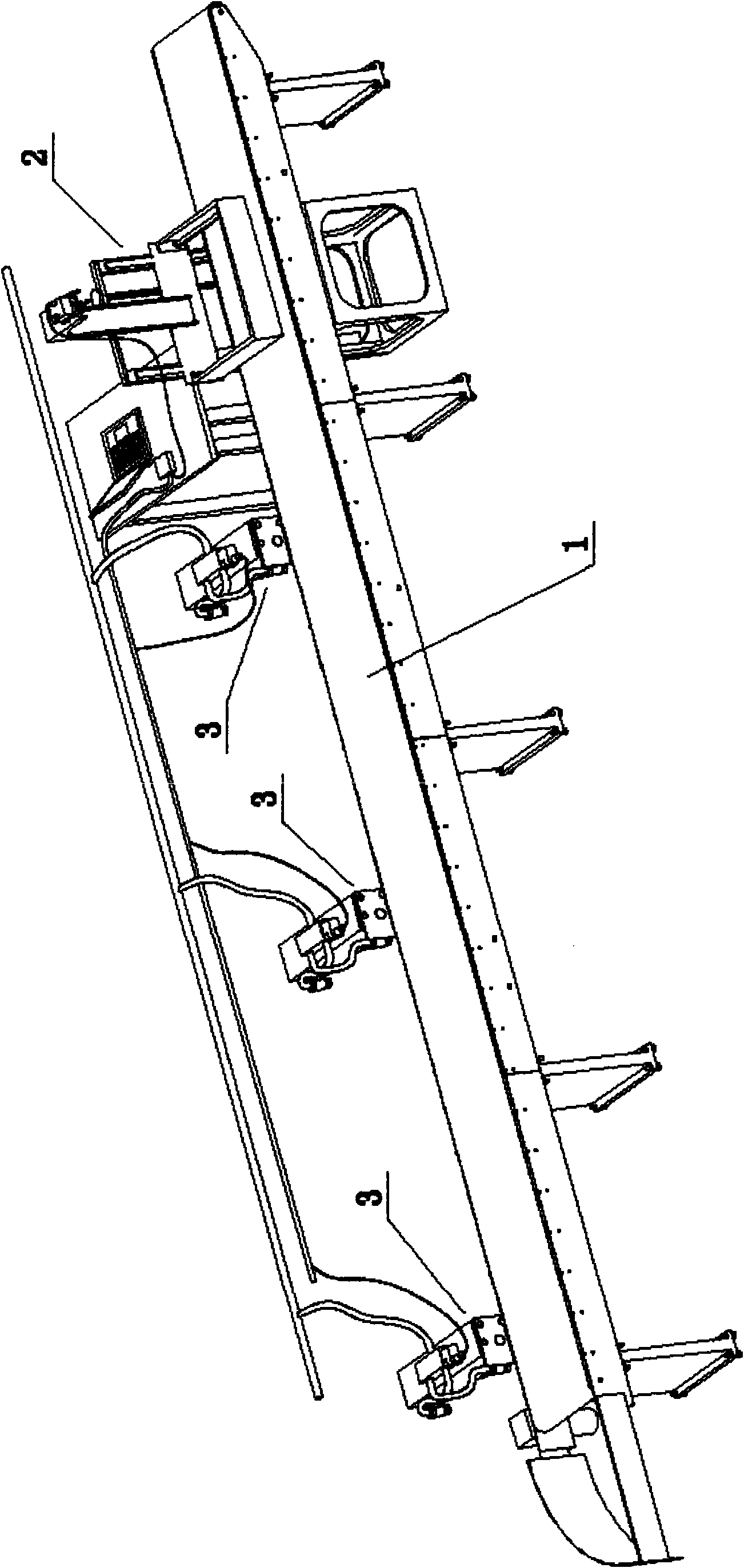

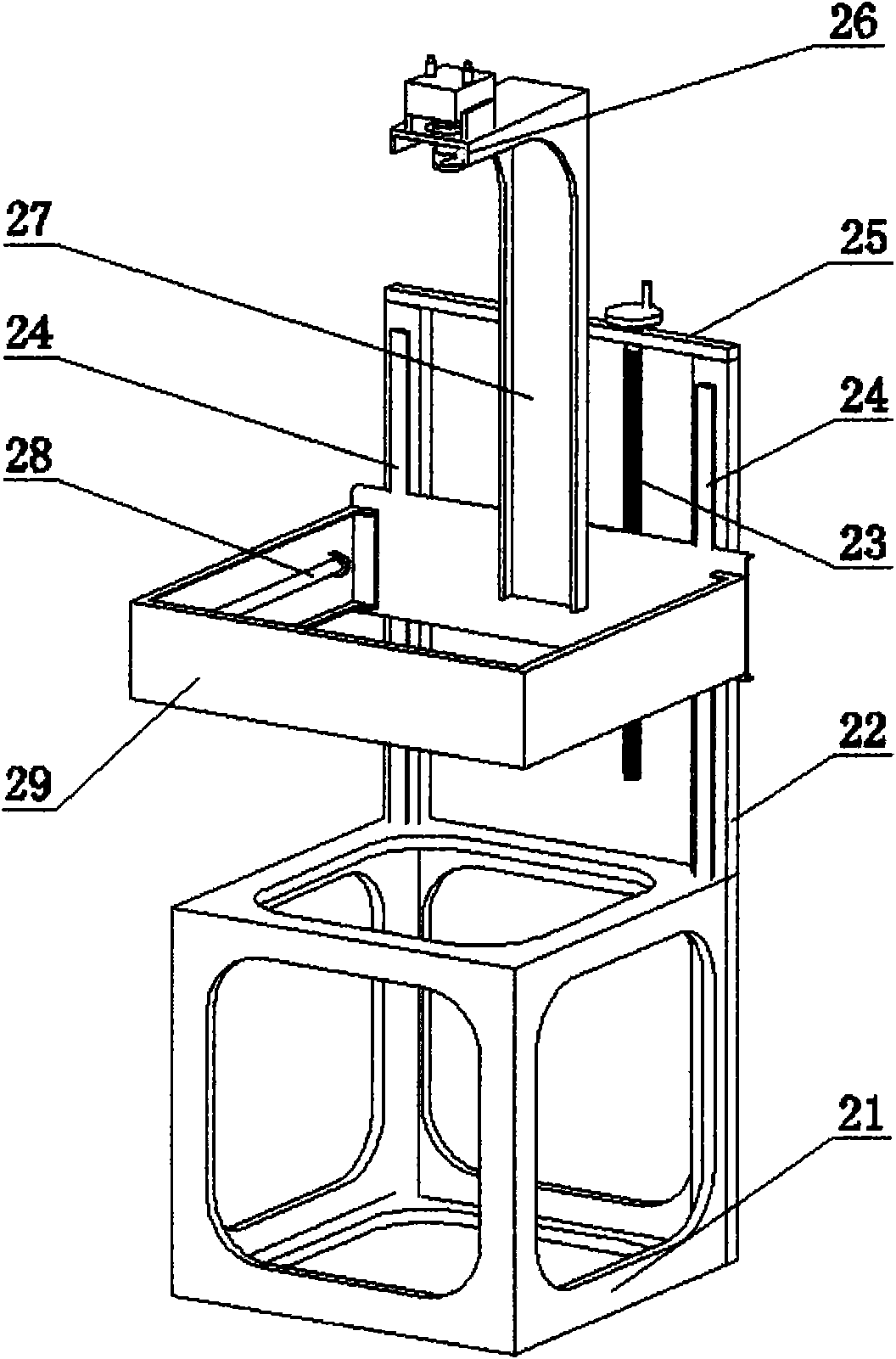

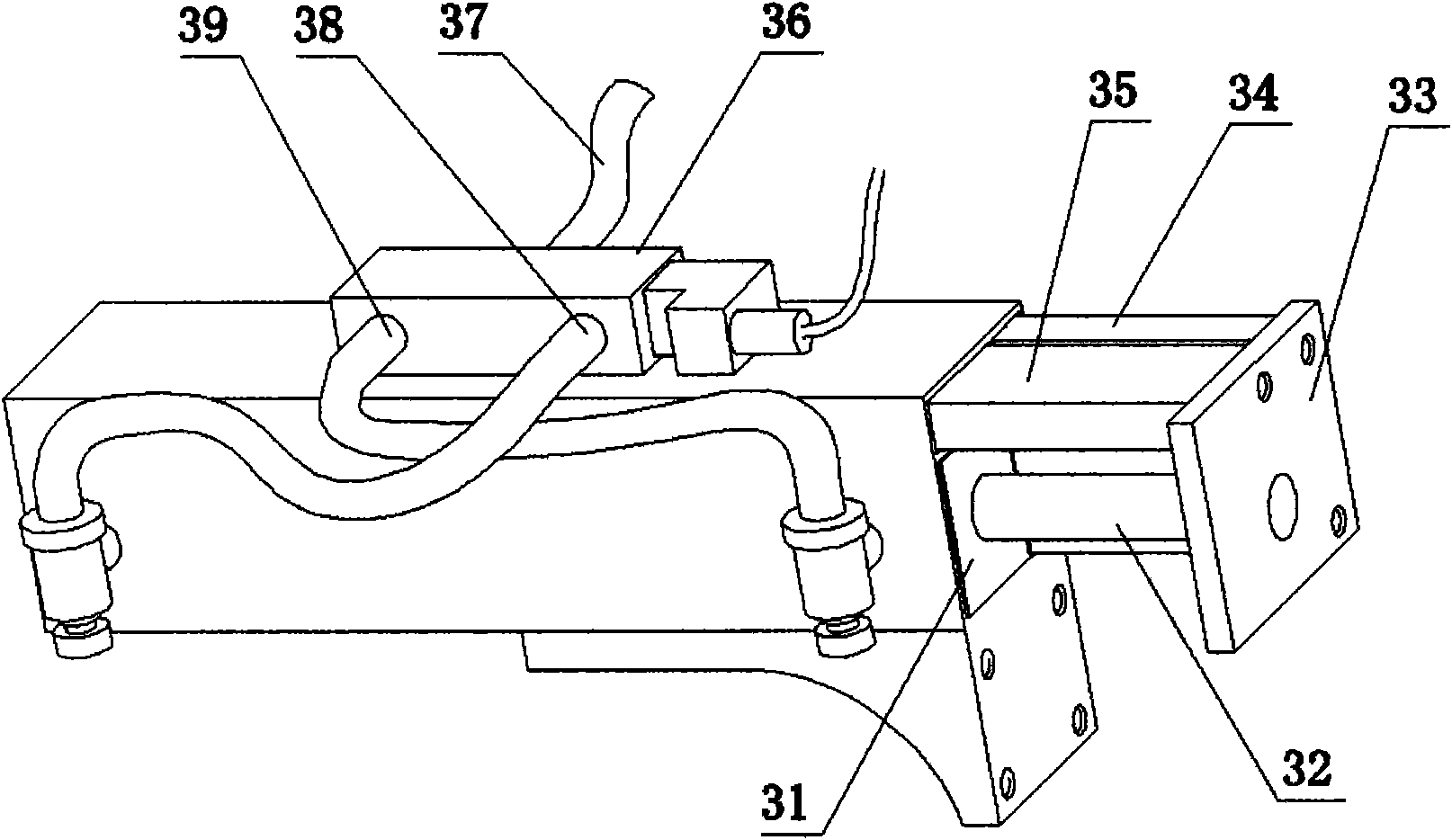

[0032] Embodiment 2: as figure 1 As shown, a device for sorting wood according to color and wood grain, it includes a wood conveyor belt 1, a wood video imaging device 2, several wood sorting devices 3 and a program control system, and the video imaging device 2 is installed at the beginning of the wood conveyor belt 1 At the end, a number of wood sorting devices 3 are equidistantly installed on the side of the wood conveyor belt 1 downstream of the video imaging device 2, and the video imaging device 2 and a number of wood sorting devices 3 are respectively connected to the program control system circuit. Such as figure 2 Shown, described video imaging device 2, it comprises a base 21, and a door font frame 22 is installed on one side of base 21, slideway 24 is arranged on the two columns of frame 22, and a shading cover 29 is slidably installed on the slideway 24 Lighting lamp 28 is installed on the inside of hood 29, a support 27 is fixed above the hood 29, a camera 26 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com