Compound electrode plate and PECVD deposition box and PECVD system

A composite electrode, deposition box technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problem of difficulty in flexible adjustment of electrode plate spacing, and achieve the effect of uniform discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

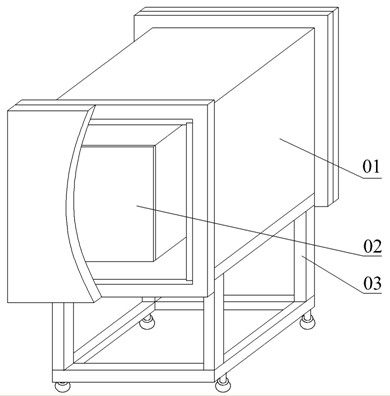

[0020] figure 1 It is a schematic diagram of the appearance of the PECVD system equipment of the first embodiment. Such as figure 1 As shown, the PECVD system related to the present invention is mainly composed of a vacuum chamber 01 , a deposition box 02 and a support 03 .

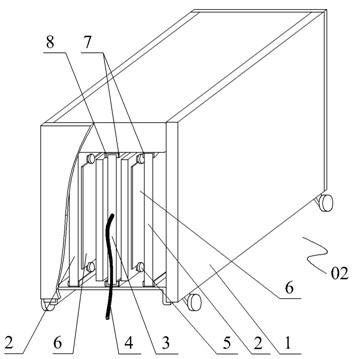

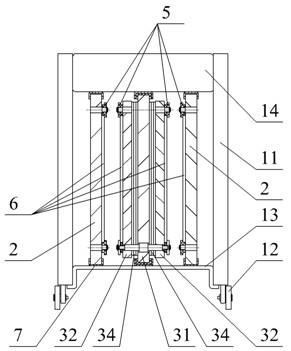

[0021] figure 2 It is a schematic diagram of the appearance of the PECVD deposition box of the first embodiment. As shown in the figure, the deposition box 02 is composed of a deposition box casing 1 , an anode electrode plate 2 , a composite electrode plate 3 as a cathode, a fixing slot 7 and an insulating slot 8 . The composite electrode plate 3 and the anode electrode plate 2 as the cathode are placed in the middle of the upper fixing plate 14 and the lower fixing plate 13 of the deposition box shell 1, respectively fixed in the fixing slots 7 welded thereon. An insulating groove 8 is installed in the fixing groove 7 where the fixing piece 31 contained in the composite electrode plate 3 is plac...

Embodiment 2

[0025] The PECVD system of the present embodiment, the PECVD deposition box and the composite electrode plate are the same as those of Embodiment 1, the difference is that the movable sheet of the composite electrode plate remains non-parallel to a certain extent (such as Figure 7 As shown), so that the anode plate and the cathode plate are not parallel, the distance between the upper electrode plate is 25mm, and the distance between the lower electrode plate is 20mm. The uneven performance of the electrode plate discharge balances the inhomogeneity of the air flow, and finally a relatively uniform film is prepared.

Embodiment 3

[0027] The PECVD system of the present embodiment, the PECVD deposition box and the composite electrode plate are the same as those of Embodiment 1, the difference is that a plurality of composite electrode plates 3 as cathodes can be arranged alternately with a plurality of anode electrode plates 2 to form an electrode plate array ( Such as Figure 8 shown). The electrode plate array technology can significantly improve the efficiency of PECVD film preparation and reduce the cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com