Elastic clip type vending machine discharging device and method

A technology of automatic vending machine and shipping device, which is applied in the directions of coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc., which can solve the problem of reducing The sliding thrust of the push plate, unfavorable product promotion, increased friction between the bottle and the barriers on both sides of the cargo channel, etc., to achieve the effect of helping reset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

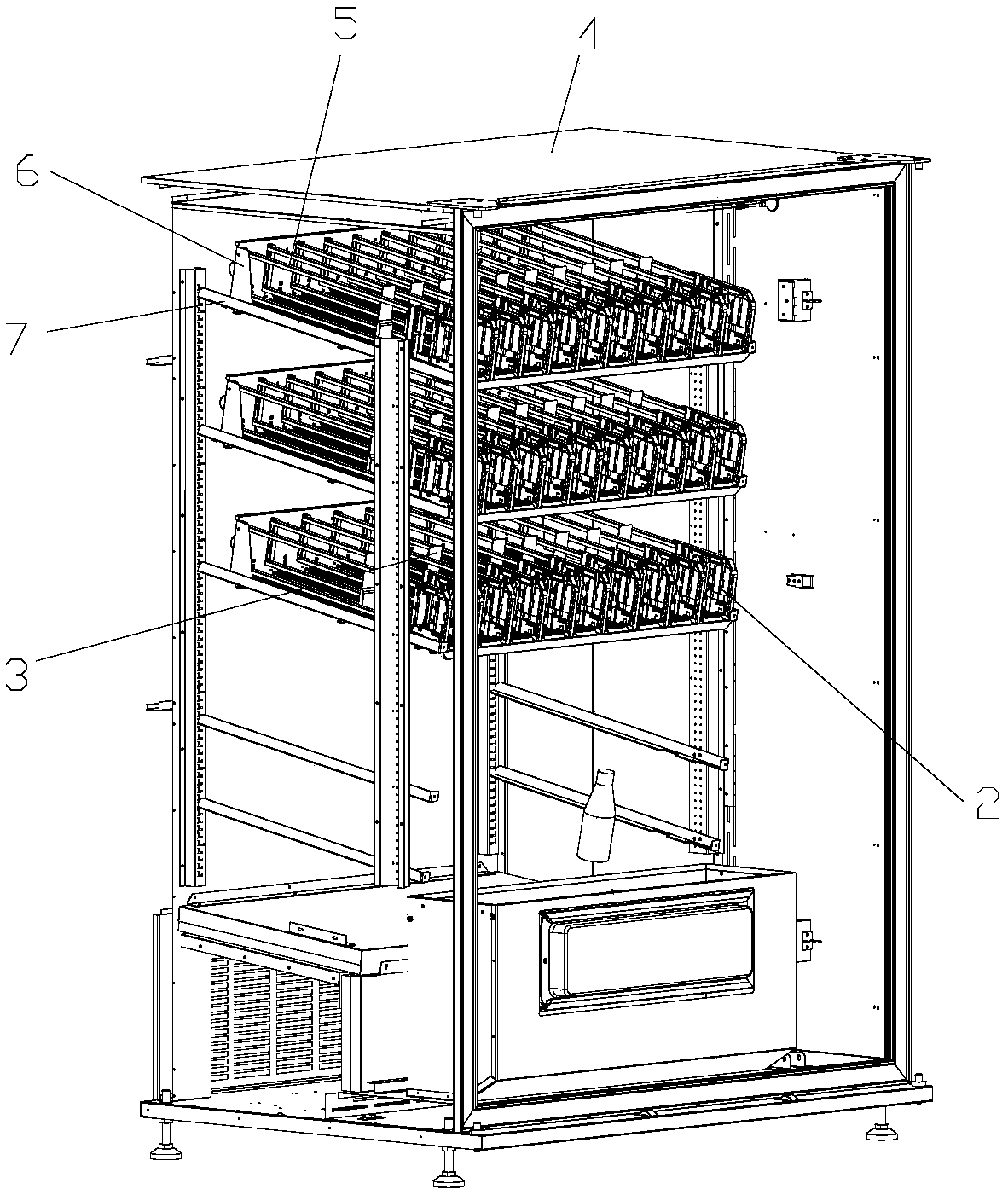

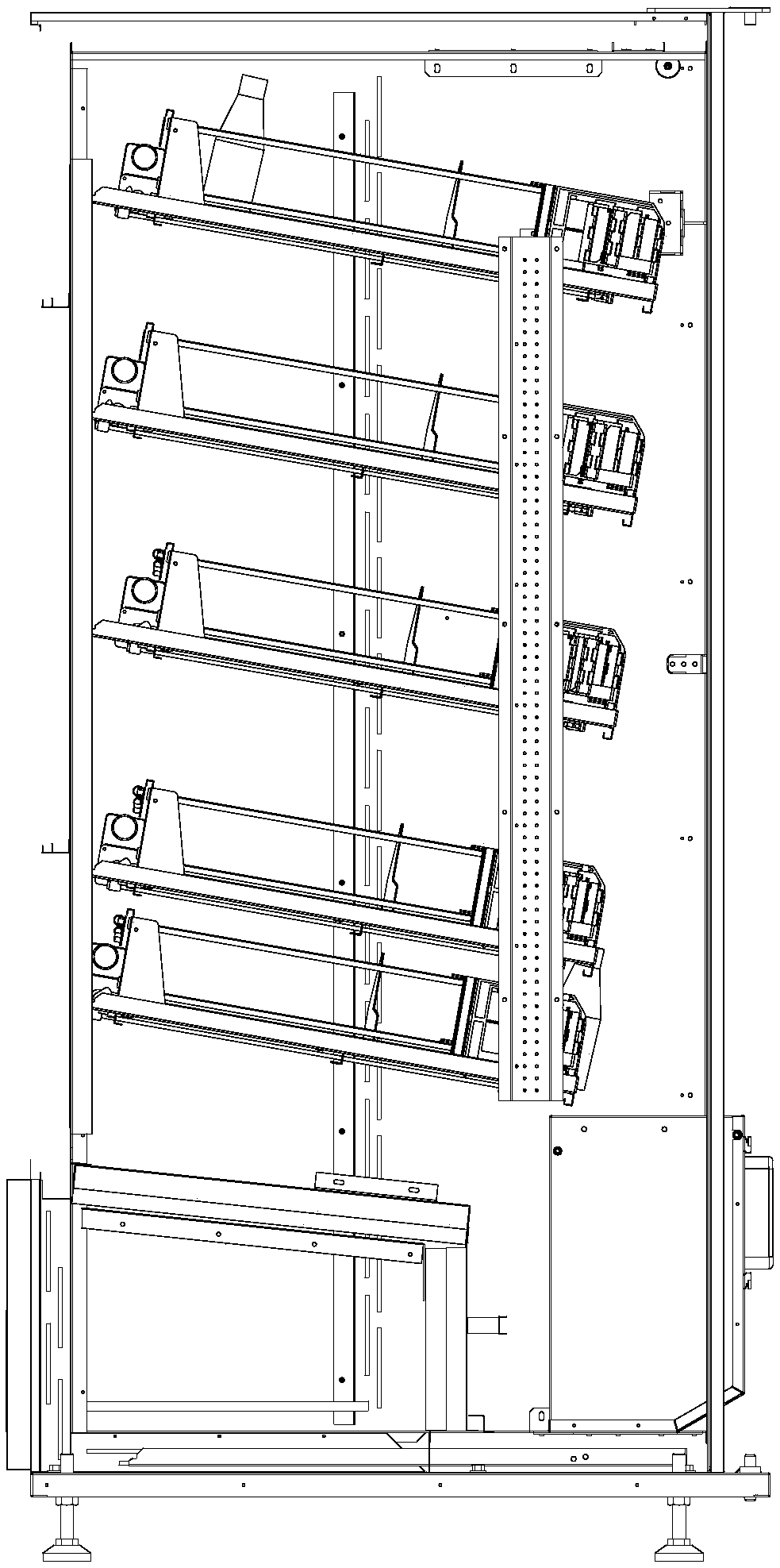

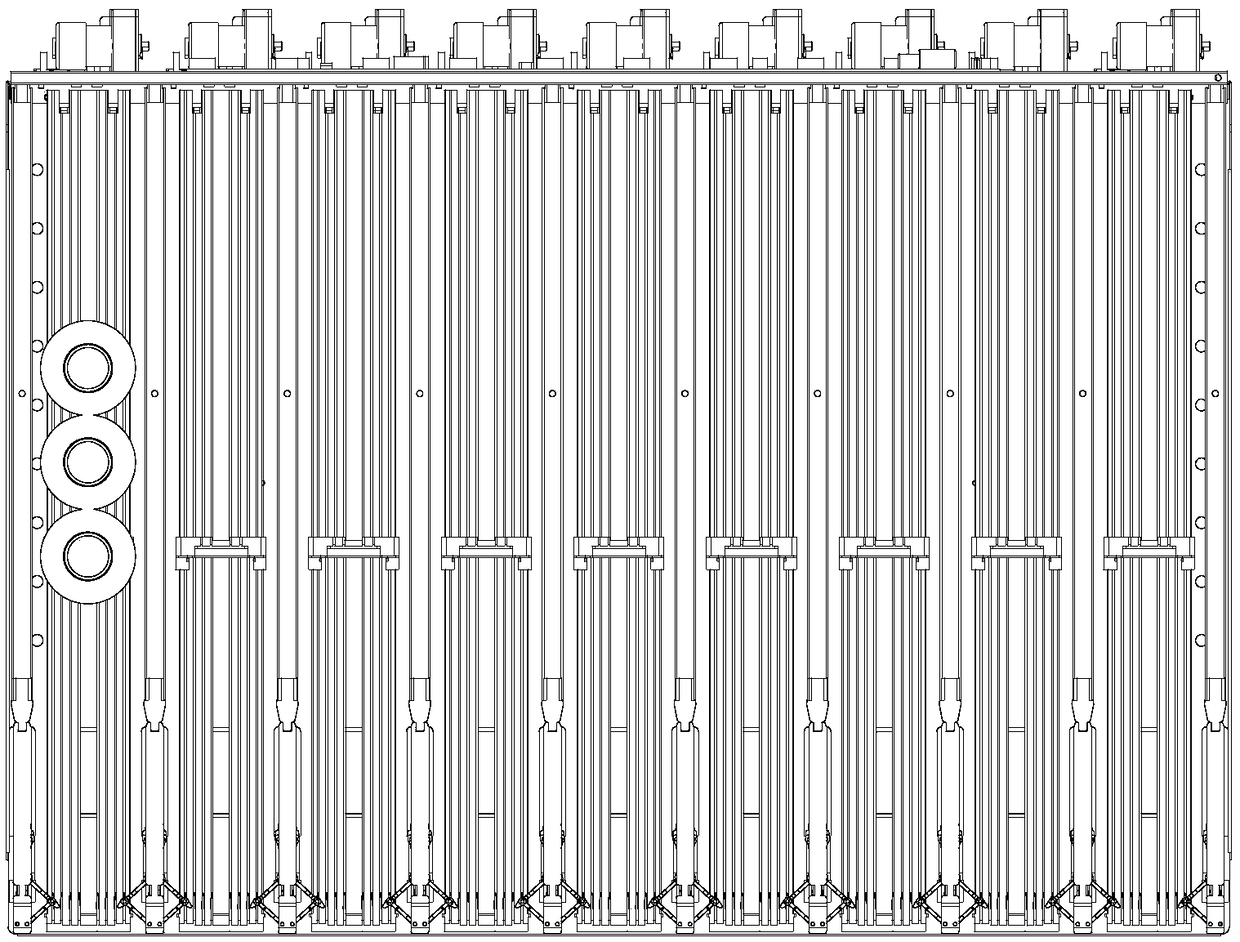

[0095] Such as Figure 1-12 A clip-type automatic vending machine delivery device, including a push plate mechanism, a gate mechanism and a gate driving mechanism, the gate mechanism is a hinged gate mechanism;

[0096] The push plate mechanism is used to provide outward thrust for the items on the cargo lane;

[0097] The gate mechanism is arranged at the delivery port of the shelf, which is closed to prevent the items from being pushed out when not being shipped, and opened to allow the items to be pushed out when the goods are shipped;

[0098]The gate driving mechanism is used to drive the switch of the gate mechanism;

[0099] The gate driving mechanism is a combination of a cam-based driving mechanism and a manual pressing-based driving mechanism;

[0100] The driving mechanism based on manual pressing includes a push rod and a button; the button is connected with the hinged gate mechanism through the push rod.

[0101] The hinged gate mechanism includes two hinges ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com