Body of horizontal rolling machine

A body, cross-rolling technology, applied in the direction of metal rolling mill stand, metal rolling stand, metal rolling, etc., can solve the problems of weak impact resistance, large area and high cost, and achieve strong impact resistance, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is specifically described below by the embodiment, only for further illustrating the present invention, can not be interpreted as the limitation of protection scope of the present invention, the technical engineer of this field can make some non-essential improvements and improvements to the present invention according to the content of the above-mentioned invention Adjustment.

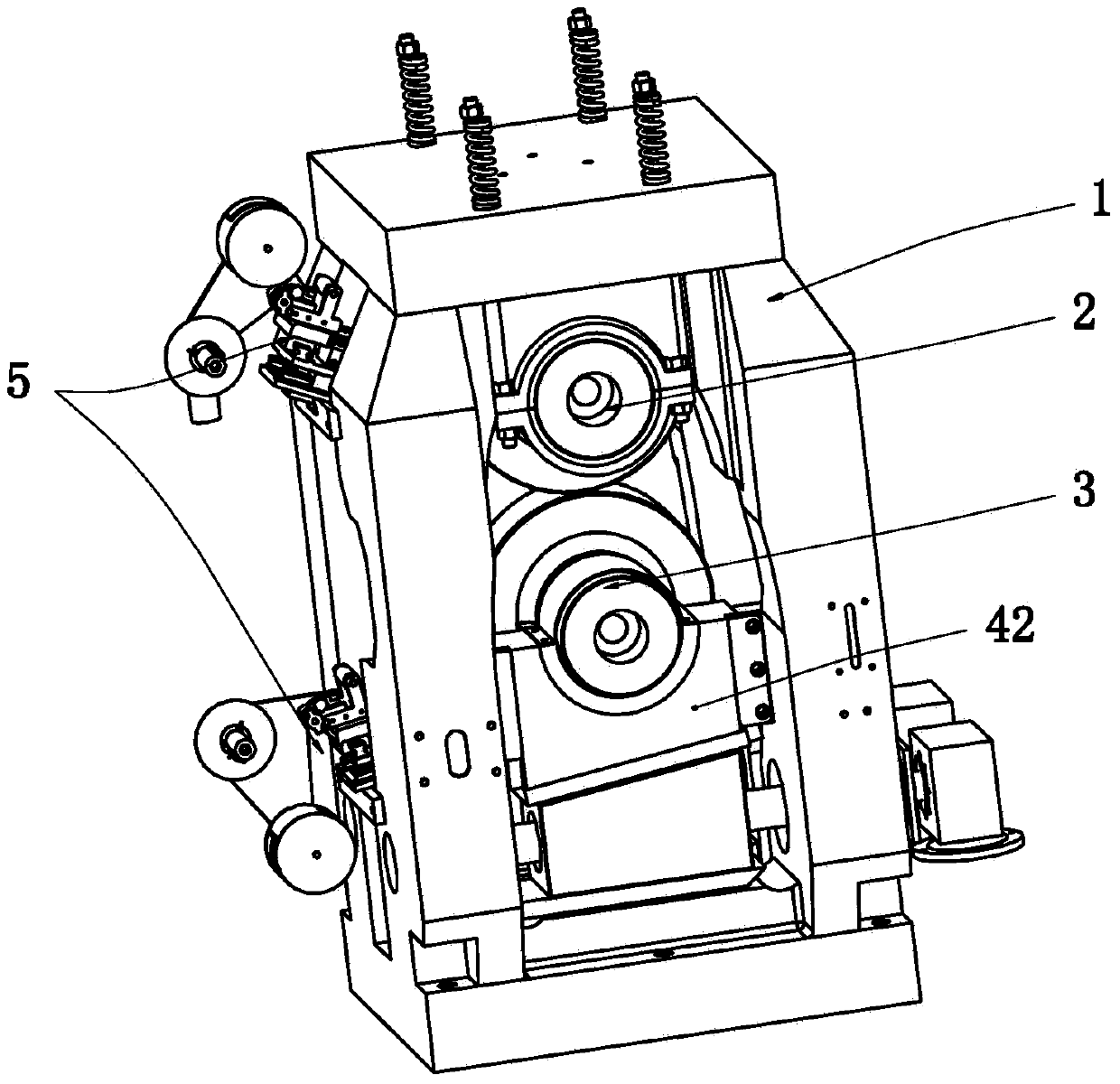

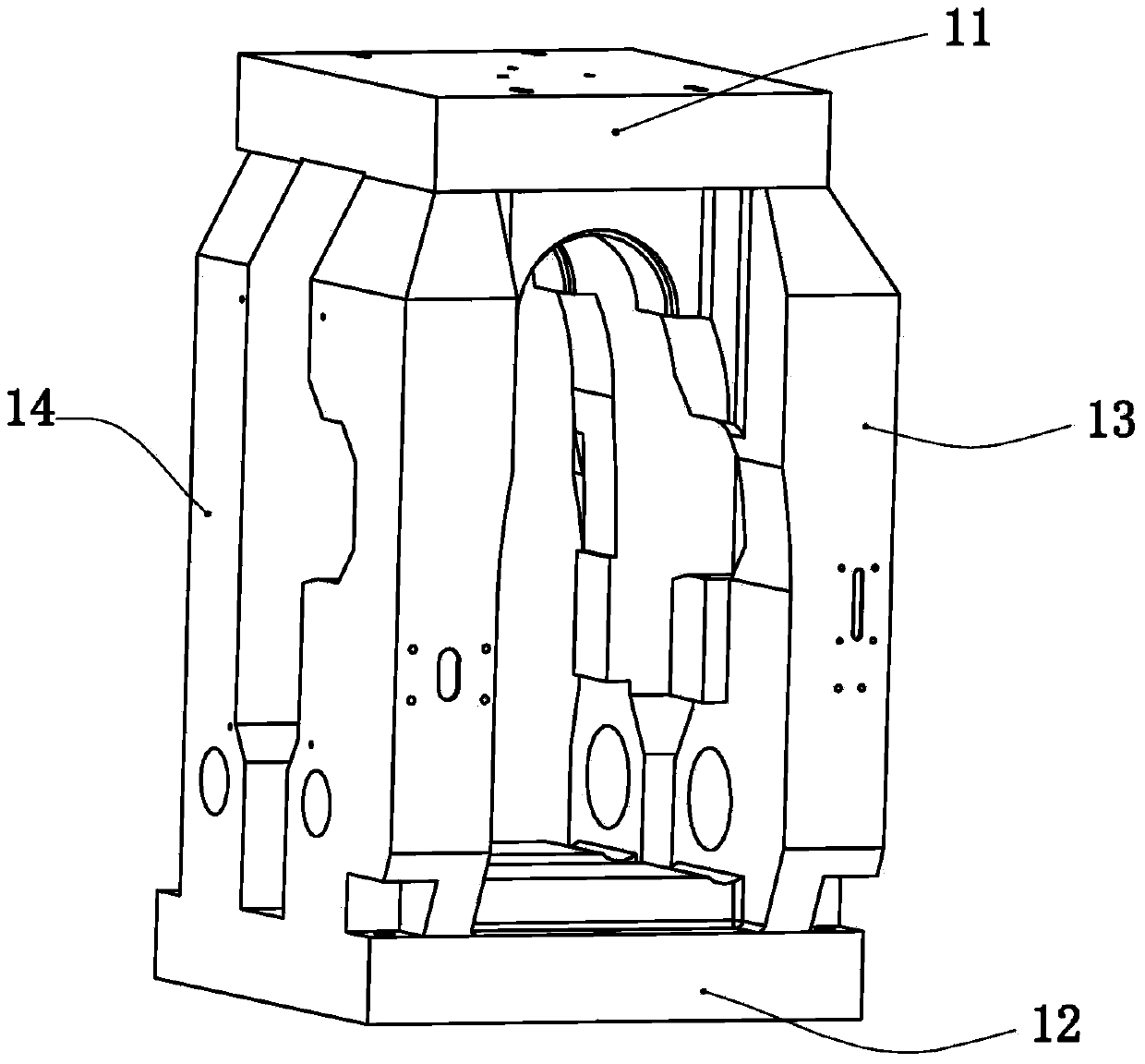

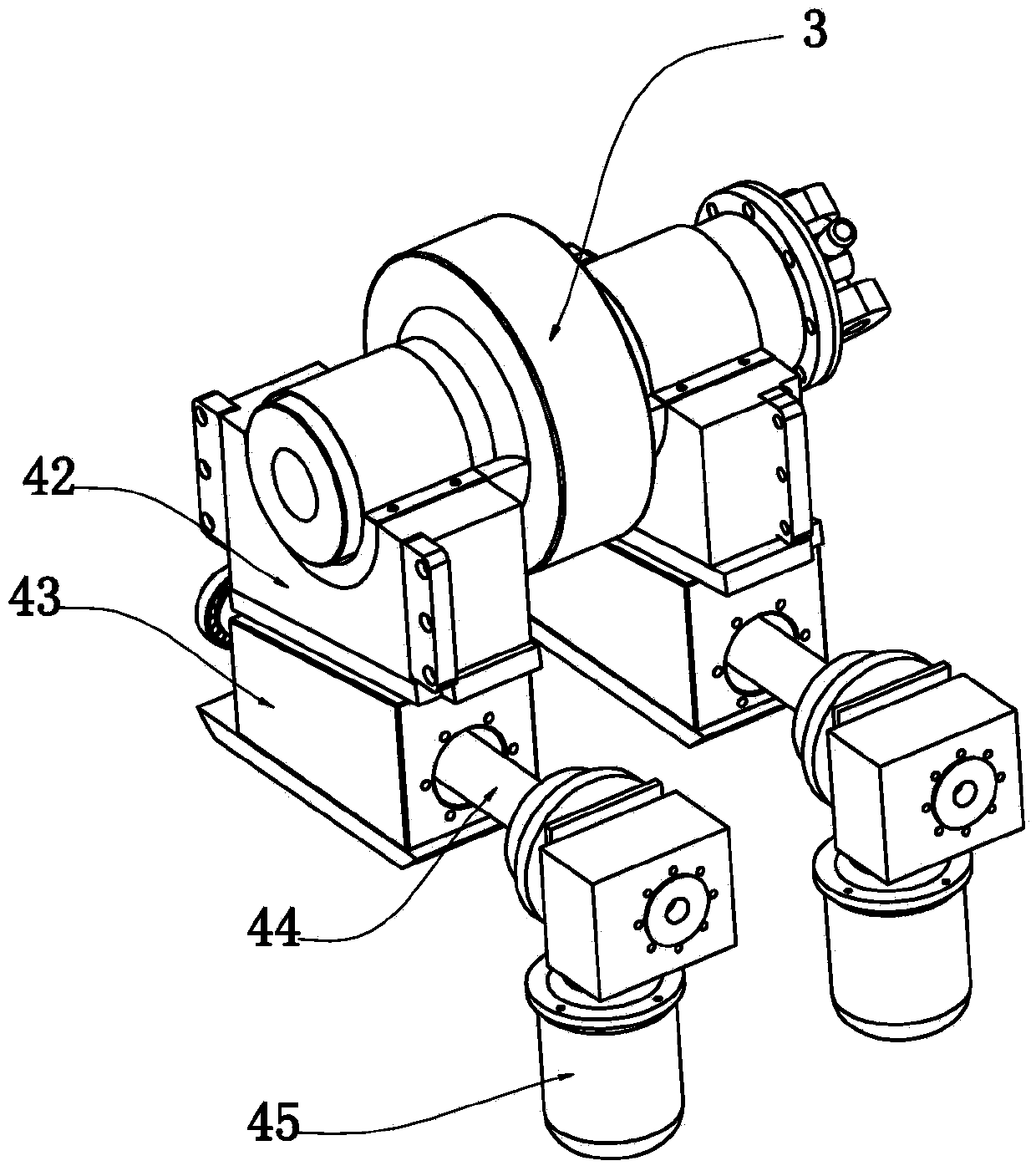

[0025] Such as Figure 1-8 The shown embodiment of the present invention includes a frame 1, which includes a top beam 11, a column and a base 12, and an upper pressure roller 2 and a lower pressure roller 3 are rotated in the frame, and the The axes of the upper pressure roller 2 and the lower pressure roller 3 are parallel to each other and arranged at intervals up and down. The uprights include a pair of front uprights 13 and a pair of back uprights 14, which are supported at four corners. Distributed between the top beam 11 and the base 12, the pair of front uprig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com